Demulsifiers for oil soluble polyalkylene glycol lubricants

A technology of copolymers and random copolymers, used in lubricating compositions, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

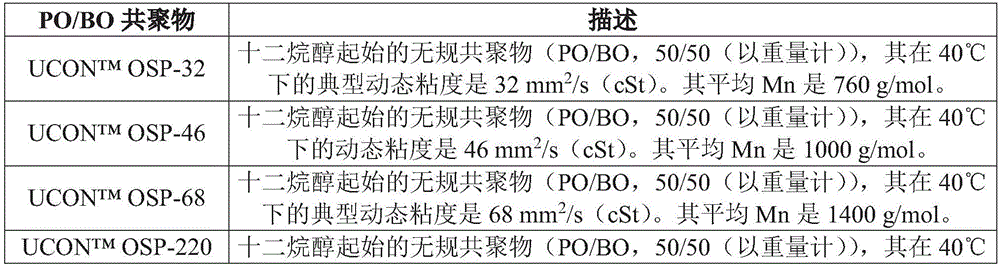

[0034] Table 1 lists the PO / BO copolymers used in the following examples. UCON is a trademark of The Dow Chemical Company.

[0035] Table 1

[0036]

[0037]

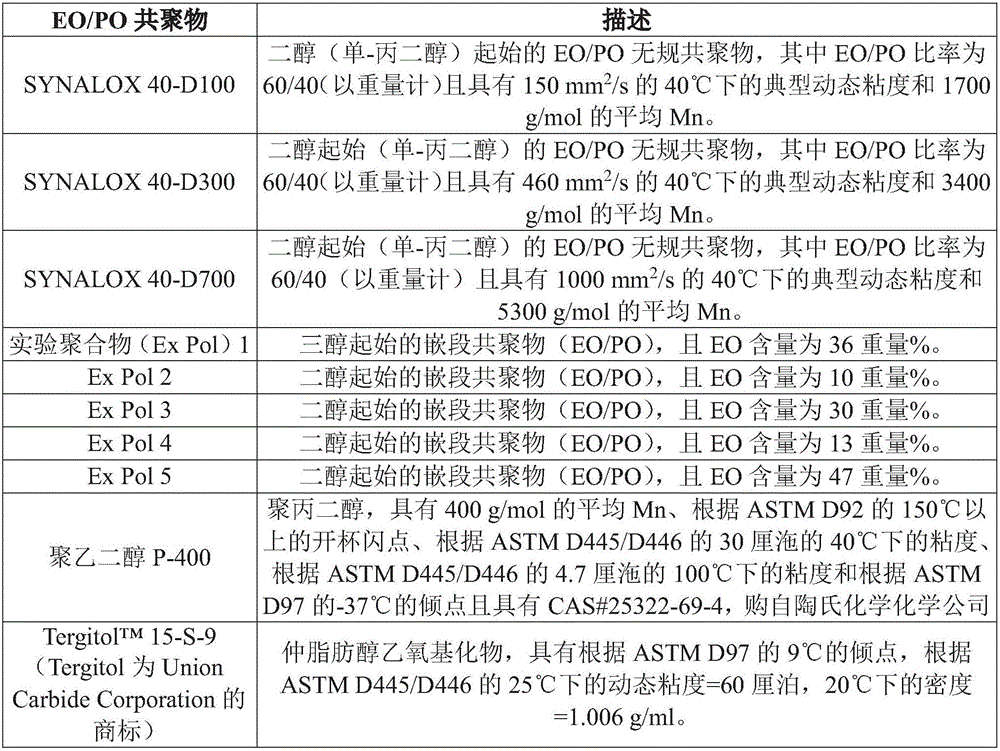

[0038] Table 2 lists the EO / PO copolymers used in the following examples. SYNALOX is a trademark of The Dow Chemical Company.

[0039] Table 2

[0040]

[0041] Prepare ExPol1

[0042] Into the reactor purged with nitrogen, an amount of starter 1 (775 grams (g)) was added to the reactor vessel (starter 1 was an ethoxylated derivative of glycerol with Mn=625). This was followed by the addition of Potassium (KOH, 25 g, 45% by weight) in water and the temperature raised to 115° C. and excess water removed in vacuo at a pressure of about 30 millibar (mbar) until the level was less than (<) as relative to the total composition 2500 parts per million (ppm) by weight. The reaction vessel was heated to 135°C and EO (1121 g) was added. Once the feeding step was complete, the reactants were digested at 135°C for a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com