Sputtering target and production method

A sputtering target and deformation direction technology, applied in the field of sputtering targets, can solve the problems of high grain size, coarsening, and insufficient defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

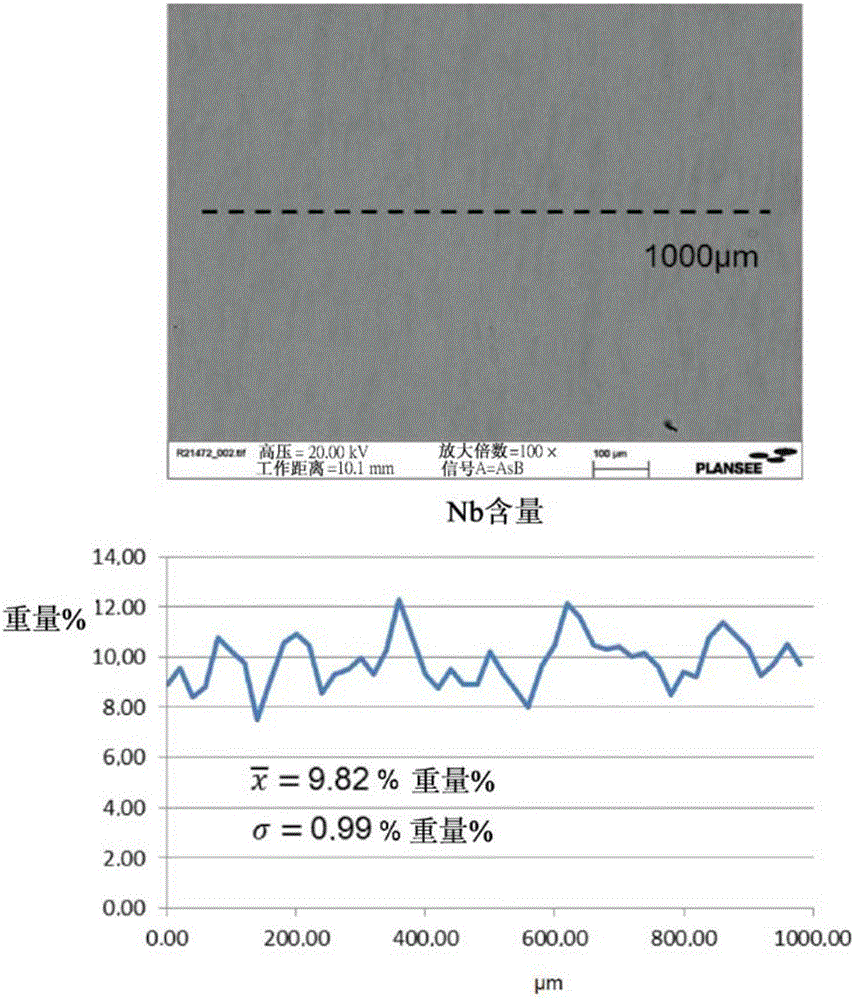

[0066] For this, use the following powders:

[0067] - Mo powder with a Fisher particle size of 4.5 μm, an oxygen content of 0.24 at % and a carbon content of 0.03 at %

[0068] - Nb powder with a Fisher particle size of 8 μm, an oxygen content of 1.26 at % and a carbon content of 0.46 at %

[0069] To obtain a Σc / Σo value of 0.7 at a Mo amount of 758 kg and a Nb amount of 81.6 kg, 0.336 kg of carbon black powder with a Fisher particle size of 0.35 μm was mixed with Mo and Nb powders in a mechanical mixer. Four flat plates were fabricated from this powder mixture by cold isostatic pressing at a pressing pressure of 180 MPa. The plates were sintered at a temperature of 2150°C and the heating process was carried out under vacuum for three hours up to a temperature of 1200°C. h 2 It is then used as a process gas. The density of the sintered body is 8.9g / cm 3 (88.6% of theoretical density), the C content is 0.022 at% and the O content is 0.018 at%. The C / O ratio was 1.22.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com