A grease composition resisting temperature fluctuation and a preparing method thereof

An oil composition and oil technology, which is applied in the fields of edible oil/fat, food science, application, etc., can solve problems such as poor resistance to temperature fluctuation, and achieve the effect of good resistance to temperature change and small hardness change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

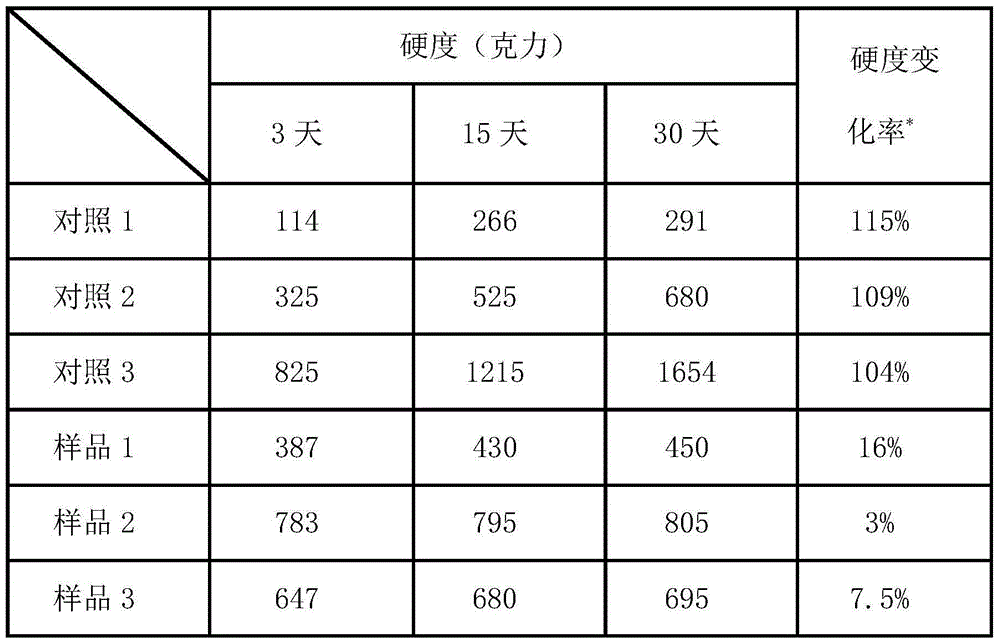

Examples

preparation example Construction

[0128] The fifth aspect of the present invention provides a method for preparing margarine. The method includes the steps of: mixing and stirring the oil composition of the present invention, quenching and kneading, and aging treatment.

[0129] In the present invention, without special instructions, the rapid cooling is to make the oil material generate crystal nuclei as soon as possible; the kneading refers to further crushing and mixing the crystal nuclei generated during the rapid cooling process, and further crystallizing the oil material.

[0130] In the present invention, the method of stirring is conventional, and those skilled in the art can directly determine the specific constants of stirring according to the description of the present invention combined with the prior art, so as to make the oils and fats mix evenly.

[0131] Rapid cooling and kneading are carried out by conventional methods in this field. For example, in a specific embodiment, the oil composition c...

Embodiment 1

[0157] Comparative Example 1: Preparation of Reference Product 1

[0158] The palm olein (IV56) was subjected to random transesterification, the catalyst used in the random transesterification treatment was sodium methoxide, and the reaction temperature of the transesterification treatment was 105°C.

[0159] After the grease composition after the transesterification is sent into the blending tank, it is stirred and mixed (stirred at 200rpm for 30min), then sent into the quencher for conventional quenching treatment (cooling at a rate of 8°C / min for 5 minutes), and then sent into the kneader The conventional kneading treatment (kneading treatment at 200 r / min for 4 minutes), and finally the conventional aging treatment (2 days at 20° C.), the prepared product was used as control 1.

Embodiment 2

[0160] Comparative example 2: preparation of reference product 2

[0161] Random transesterification of palm stearin with an iodine value of 45 and palm kernel liquid oil with an iodine value of 18 is carried out. The catalyst used in the random transesterification treatment is sodium ethoxide, and the reaction temperature of the transesterification treatment is 105°C.

[0162] After the grease composition after the transesterification is sent into the blending tank, it is stirred and mixed (stirred at 200rpm for 30min), then sent into the quencher for conventional quenching treatment (cooling at a rate of 8°C / min for 5 minutes), and then sent into the kneader The conventional kneading treatment (kneading treatment at 200 r / min for 4 minutes), and finally the conventional aging treatment (aging at 20° C. for 2 days), the prepared product was used as control 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com