Robot system for feeding white spirit to cooking pot full automatically

A robotic system and fully automatic technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve problems such as inability to spread materials, achieve compact structure, improve labor productivity, and reduce labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

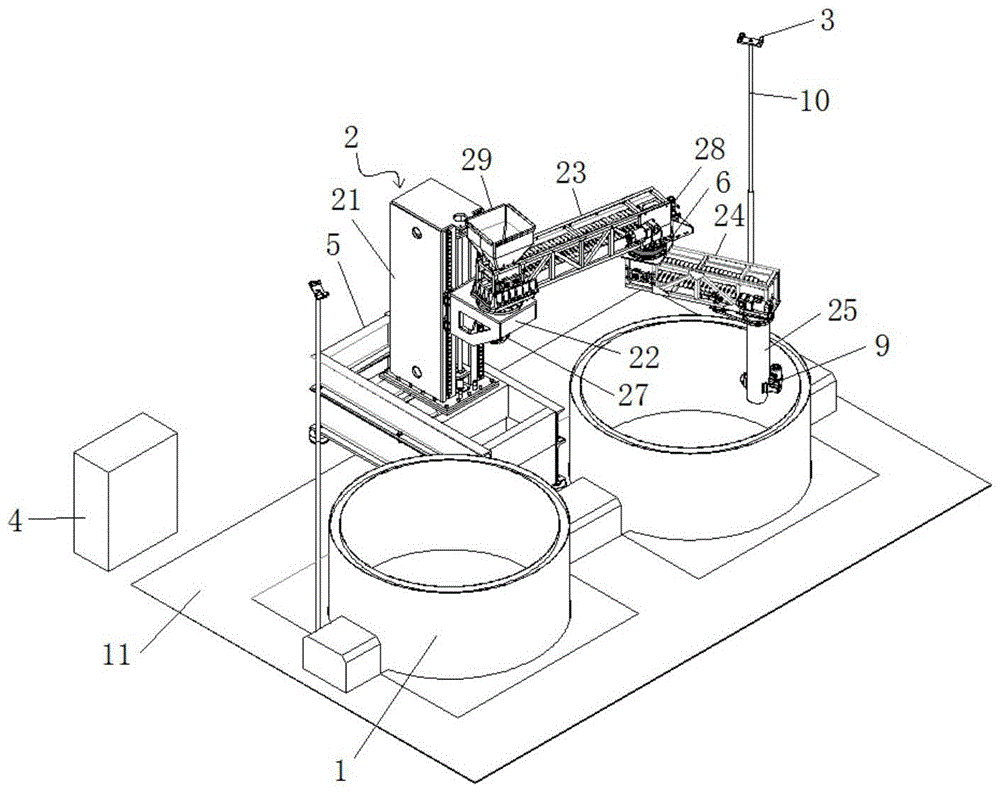

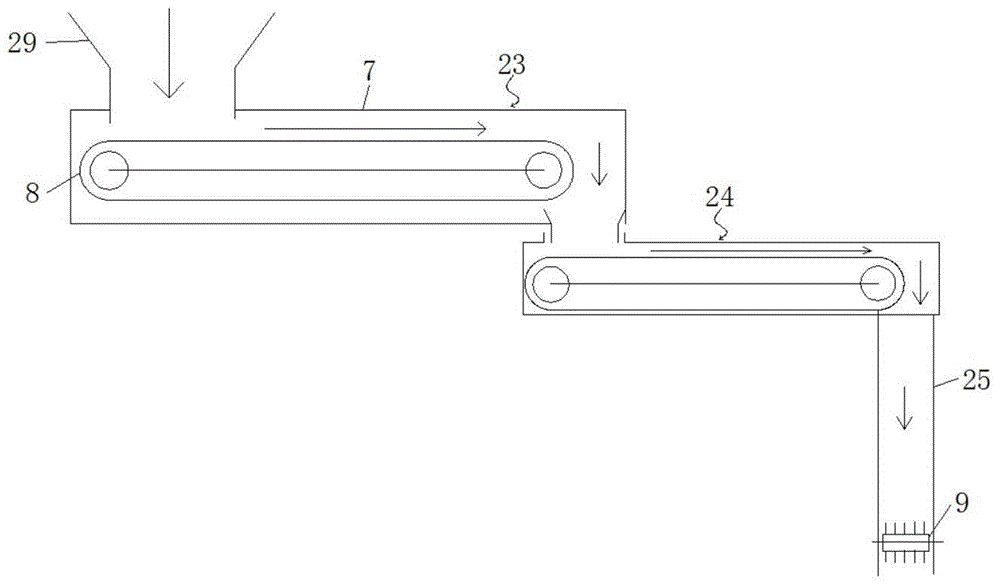

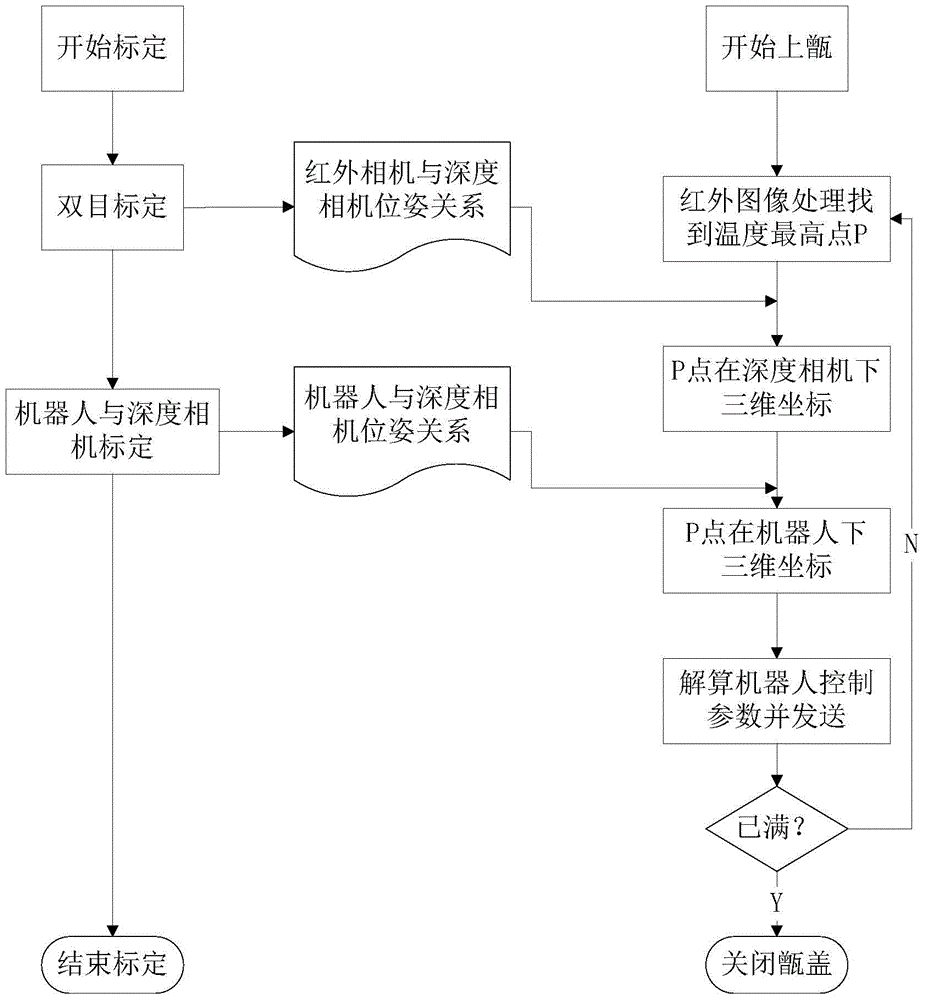

[0019] Such as figure 1 with figure 2 As shown, the structure schematic diagram of the automatic liquor filling robot system of the present invention includes a steamer pot 1, a SCARA robot 2, a sensor module 3 and a computer 4; the steamer pots 1 are arranged side by side on the bottom plate 11; On the bottom plate 11 between adjacent retorts 1, the base 5 is customized according to the situation of the on-site retorts. The effective working range of the SCARA robot 2 can just cover two adjacent retorts. The SCARA robot 2 includes a lifting arm 21, a lifting platform 22, a large Arm 23, small arm 24 and blanking cylinder 25, lifting arm 21 is fixed on the base 5, and lifting platform 22 is slidably installed on the lifting arm 21, and lifting platform 22 does vertical motion to realize the height adjustment of boom 23. 23 is hinged on the lift plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com