Contactless power supply coupling device for magnetic-levitation train and magnetic-levitation train

A non-contact power supply, maglev train technology, applied in electric traction, electric vehicles, electric energy management and other directions, can solve the problems such as the inability to realize the movement of the magnetic flux relative to the generator coil, the inability of the permanent magnet to slot and lay the coil, and the unworkable linear power generation scheme. , to achieve the effect of reducing the weight of the car body and maintenance management, facilitating maintenance and saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

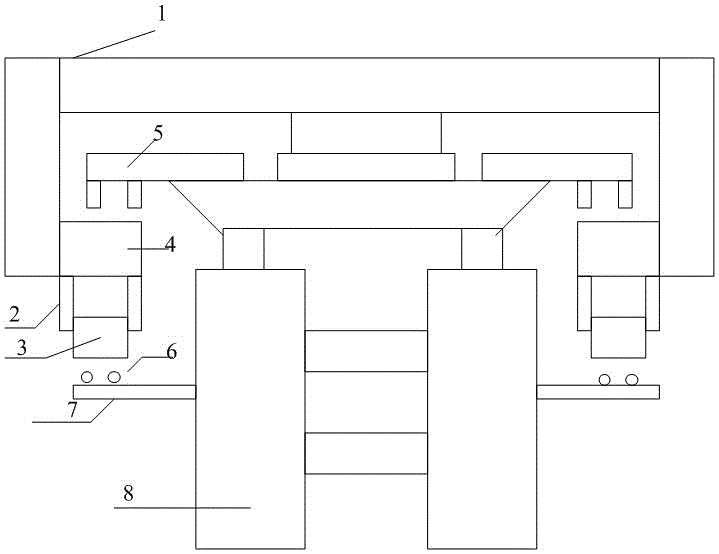

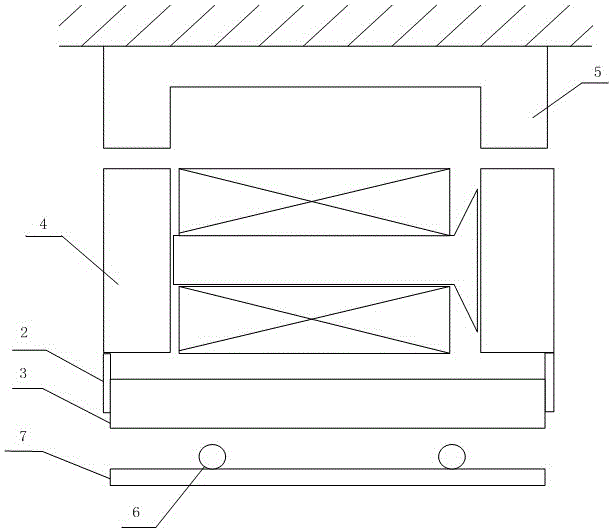

[0025] see figure 1 and figure 2 , figure 1 It is a schematic diagram of the installation of a non-contact power supply coupling device for a maglev train provided by the present invention, figure 2 for figure 1 left view of .

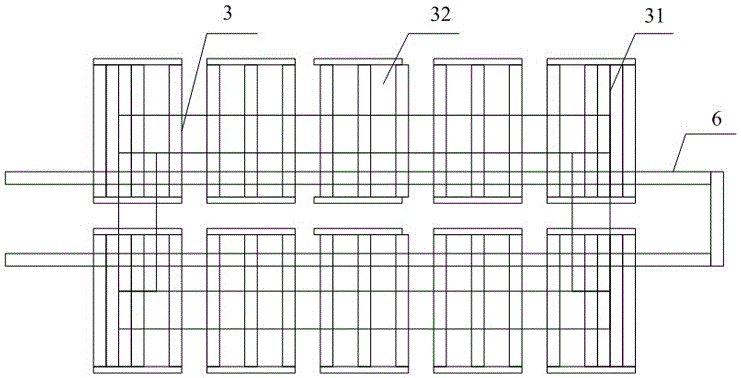

[0026] The non-contact power supply coupling device for maglev trains includes a transmitting end 6 and a receiving end 3, wherein: the receiving end 3 is installed under the suspension electromagnet 4 on one side of the train through the receiving end bracket 2 parallel to the ground, and the receiving end 3 is formed by a multi-turn rectangular coil It is formed in series in a spiral shape, and the two ends of the coil are connected with the lower-level power equipment, and the high-frequency current is converted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com