High-temperature steam electrolytic hydrogen production system using medium-low-temperature heat source

A low-temperature heat source and high-temperature steam technology, which is applied in the field of high-temperature steam electrolysis hydrogen production system, can solve the problems of practical application limitations of solid oxide electrolyzers, increased process complexity and uncertainty, etc., so as to reduce heating costs and improve overall efficiency. Efficiency, the effect of avoiding oxygen corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

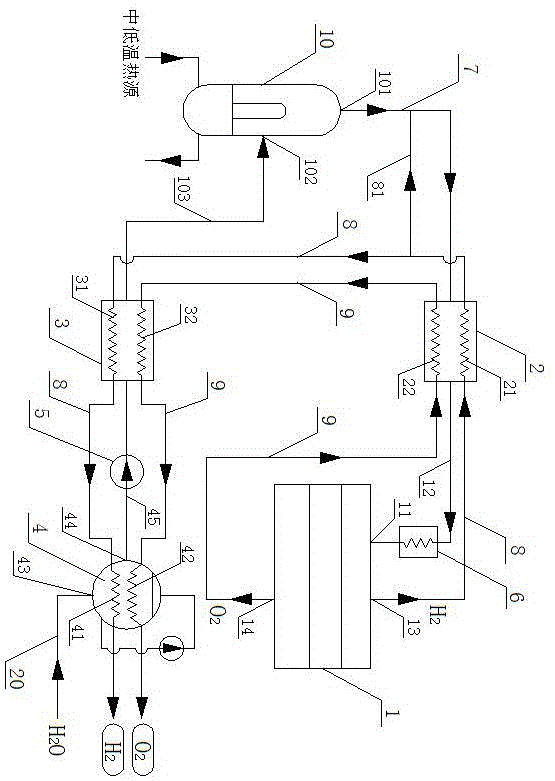

[0013] Such as figure 1 As shown, the present invention is a high-temperature steam electrolysis hydrogen production system using medium and low temperature heat sources, which includes a steam generator 10, a solid oxide electrolyzer 1, a regenerative superheater 2, a regenerative heater 3, and a deaerator 4 , Feed water pump 5, auxiliary electric heater 6, water vapor pipeline 7, hydrogen delivery pipeline 8, oxygen delivery pipeline 9, raw water pipeline 20; the steam outlet 101 of the steam generator 10 is connected to the return line through the steam pipeline 7 The shell side of the thermal superheater 2 is connected, the feed water inlet 102 of the steam generator 10 is connected to the shell side of the regenerative heater 3 through the first pipe 103; the cathode water vapor inlet 11 of the solid oxide electrolyzer 1 passes through the The second pipeline 12 is connected to the shell side of the heat recovery superheater 2, and an auxiliary electric heater 6 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com