Electronic smoke atomizer based on hot airflow non-contact heating

An electronic cigarette vaporizer and non-contact heating technology, applied in the field of electronic cigarettes, can solve problems such as the generation of harmful substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

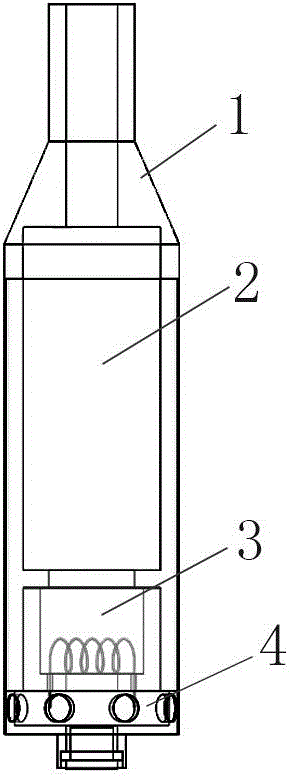

[0019] refer to figure 1 , an electronic cigarette atomizer structure based on non-contact heating of hot air flow, including a mouthpiece 1, an atomizing chamber 2, a heating component 3 and a battery connection component 4.

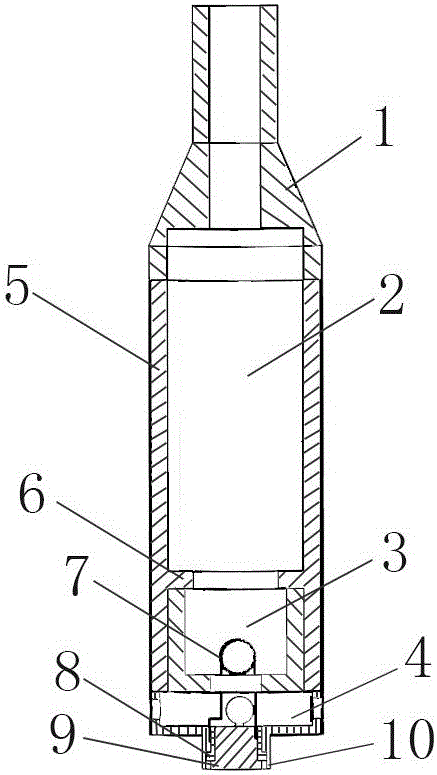

[0020] refer to figure 2 , a cross-sectional structure of an electronic cigarette atomizer based on non-contact heating of hot air flow, including a mouthpiece 1, an atomizing chamber 2, a heating component 3 and a battery connection component 4.

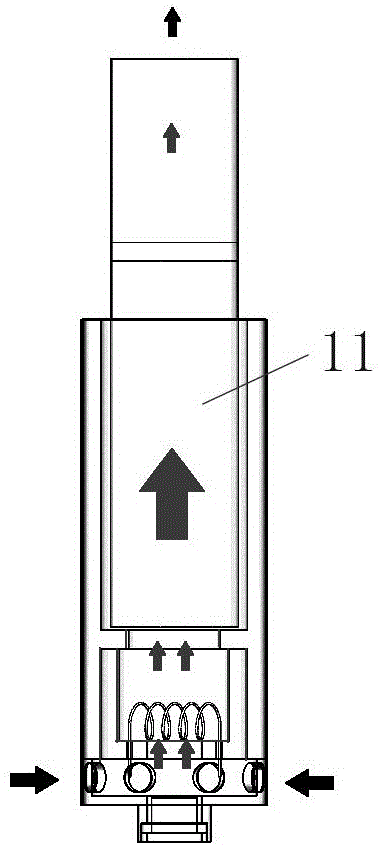

[0021] refer to image 3 , a schematic diagram of the air flow of the electronic cigarette vaporizer in use. When in use, the cigarette holder 1 does not need to be included, but the low-temperature cigarette 11 needs to be inserted into the atomizing chamber, and the direction of the arrow indicates the flow direction of the air.

[0022] The heating assembly 3 and the battery connection assembly 4 are connected in the following manner: one end of the heating wire 7 is tightly pressed with the fixing sea...

specific Embodiment 2

[0027] refer to figure 1 , an electronic cigarette atomizer structure based on non-contact heating of hot air flow, including a mouthpiece 1, an atomizing chamber 2, a heating component 3 and a battery connection component 4.

[0028] refer to figure 2 , a cross-sectional structure of an electronic cigarette atomizer based on non-contact heating of hot air flow, including a mouthpiece 1, an atomizing chamber 2, a heating component 3 and a battery connection component 4.

[0029] refer to Figure 4 , a schematic diagram of the air flow of the electronic cigarette vaporizer in use. When in use, it is necessary to use a solid pod 12 made of aromatic plant powder and put it into the atomization chamber, and the direction of the arrow indicates the flow direction of the air.

[0030] The heating assembly 3 and the battery connection assembly 4 are connected in the following manner: one end of the heating wire 7 is tightly pressed with the fixing seat 10 through the outer side o...

specific Embodiment 3

[0035] refer to figure 1 , an electronic cigarette atomizer structure based on non-contact heating of hot air flow, including a mouthpiece 1, an atomizing chamber 2, a heating component 3 and a battery connection component 4.

[0036] refer to figure 2 , a cross-sectional structure of an electronic cigarette atomizer based on non-contact heating of hot air flow, including a mouthpiece 1, an atomizing chamber 2, a heating component 3 and a battery connection component 4.

[0037] refer to Figure 5 , a schematic diagram of the air flow of the electronic cigarette vaporizer in use. When in use, the cigarette holder 1 does not need to be included, but the pod 13 based on the plant rattan core containing the cigarette holder needs to be inserted into the atomizing chamber, and the direction of the arrow indicates the flow direction of the air.

[0038] The heating assembly 3 and the battery connection assembly 4 are connected in the following manner: one end of the heating wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com