Automatic coating device for automobile brake disc

A technology for automobile brakes and brake discs, which is applied to the field of automatic coating devices for automobile brake discs, can solve the problems of reducing the amount of blanks in the conveyor line, reducing the service life of the chain, and reducing the production capacity of the entire line, so as to reduce labor costs and improve efficiency. , the effect of reducing human injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

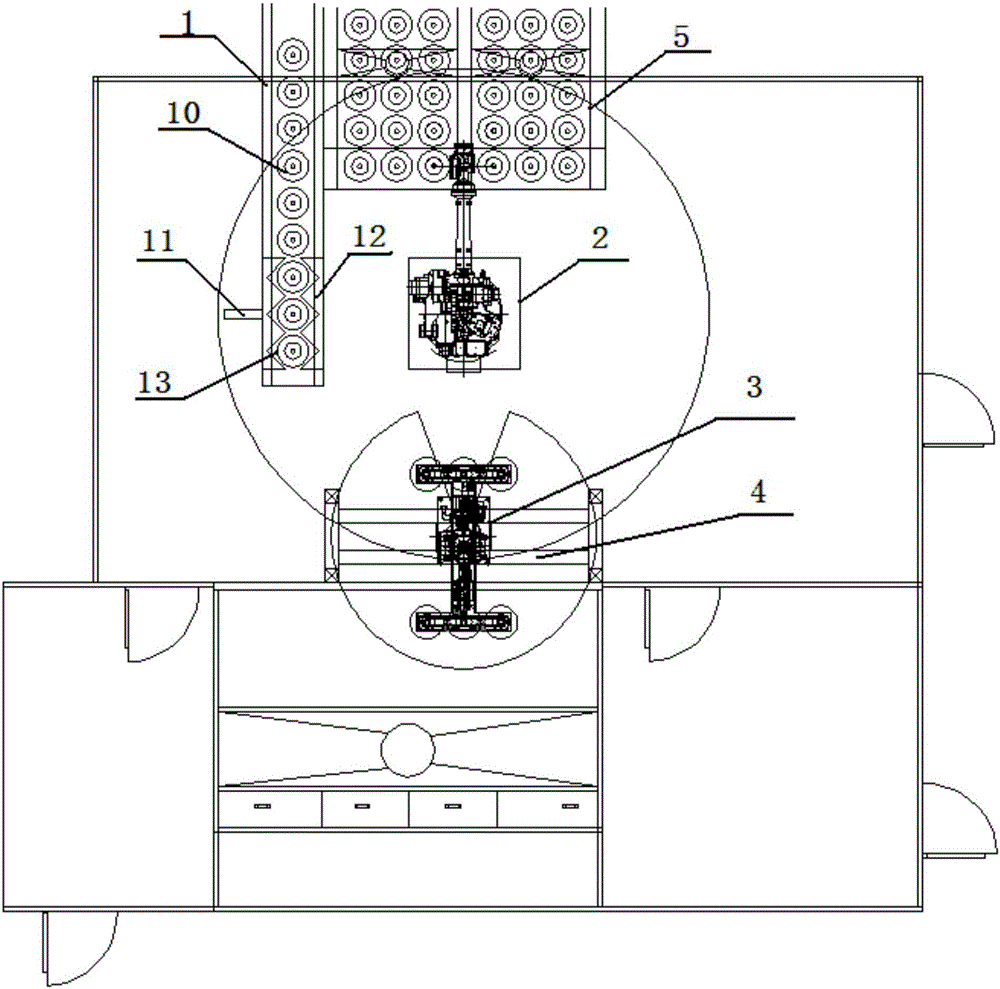

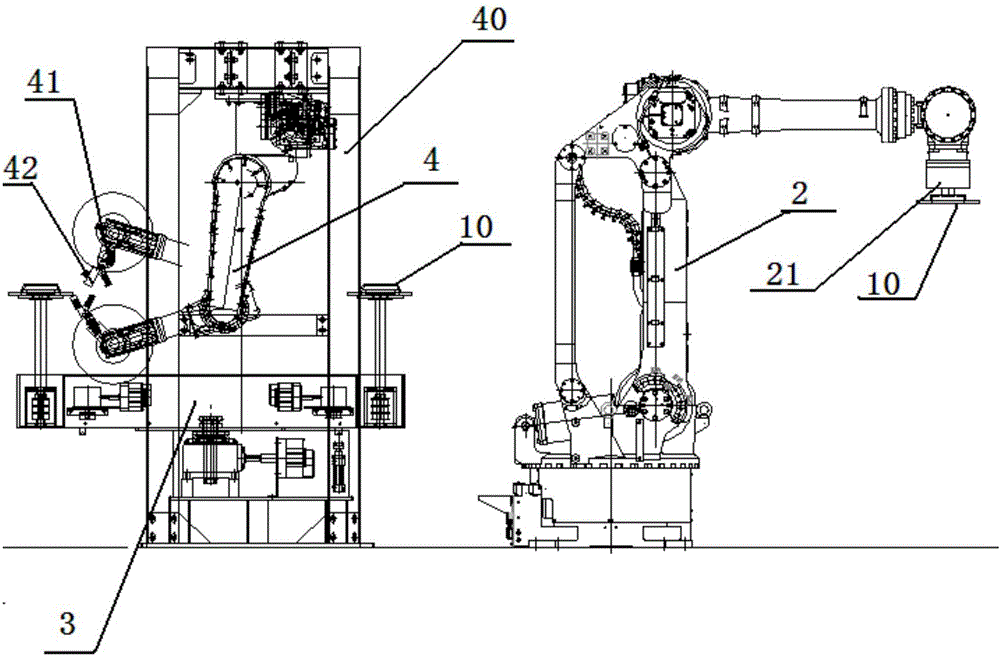

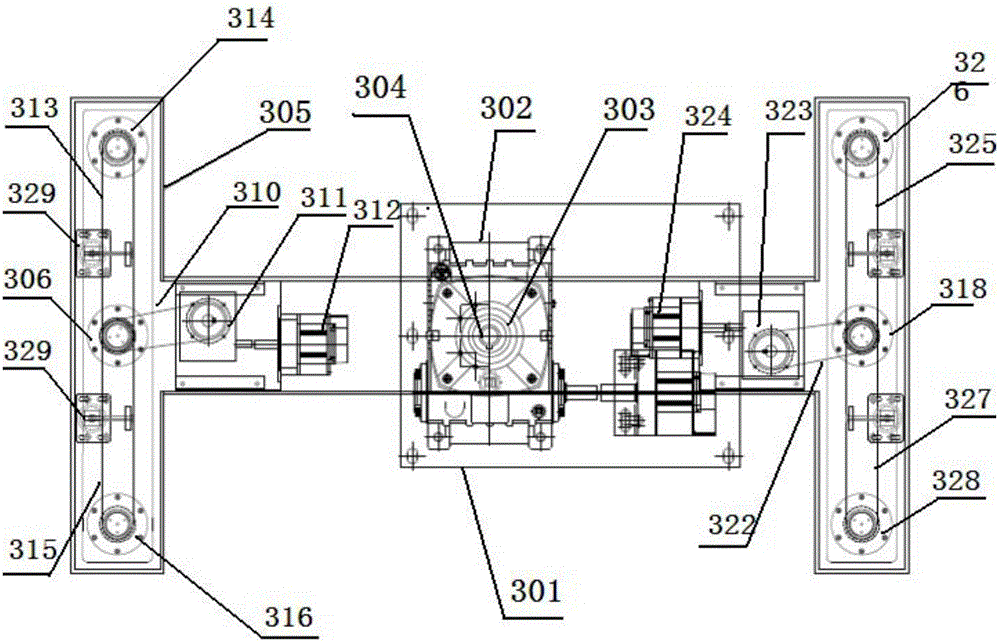

[0036] Disclosed in this embodiment is an automatic coating device for brake discs of automobiles, such as figure 1 and 2 As shown, the coating device mainly includes: feeding conveying chain 1 , handling robot 2 , turntable 3 , spraying robot 4 and discharging conveying line 5 .

[0037] The feeding conveying chain 1 is a conveying line, and the feeding conveying chain 1 is arranged at the feeding port of the device, and the feeding conveying chain 1 transports the brake disc workpiece 10 to the spray booth. In order to facilitate the handling robot 2 to carry the brake disc workpiece 10, a positioning mechanism and a jacking mechanism are arranged on the feeding conveying chain 1. The feeding station, the above-mentioned positioning mechanism includes a clamping cylinder 11 and two positioning plates 12, and the above-mentioned jacking mechanism is a jacking cylinder and a support plate driven by the jacking cylinder, because the device in this embodiment is an automatic de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com