Welding sealing method for preventing crevice corrosion between iron anode and copper alloy flange

A welding sealing and crevice corrosion technology, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of complicated installation, water seepage, crevice corrosion of iron anode 1 and copper alloy flange, etc., to achieve the effect of solving crevice corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

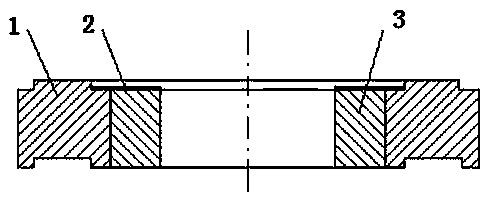

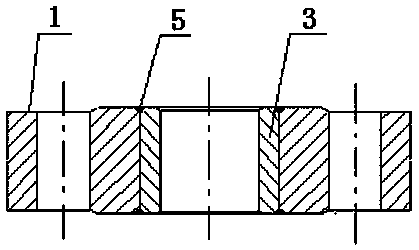

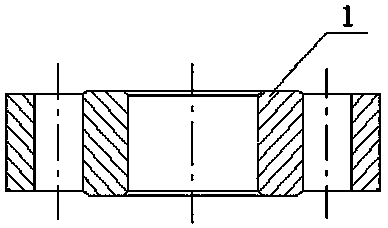

[0016] see Figure 2 ~ Figure 4 , The flanged iron anode of the present invention is assembled from a ring-shaped iron anode 1 and a copper (nickel) alloy flange 3 , and the iron anode 1 is embedded in the center hole of the copper alloy flange 3 . The iron anode 1 will preferentially dissolve in seawater, and play a role in protecting the copper pipeline of the ship connected with it. The present invention performs welding and sealing treatment on the contact ring surface (line) between the annular iron anode 1 and the copper alloy flange 3 . The weld 5 mainly plays the role of protection and sealing. Therefore, when selecting welding materials, materials with a natural potential in seawater close to the copper alloy flange should be selected as much as possible, so that the weld 3 will not be corroded by galvanic couples in seawater. Dissolves preferentially. In addition, since the physical properties of the iron anode 1 and the copper flange 3 are very different, defects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com