Packing machine

A packaging machine and feeding machine technology, applied in packaging, transportation packaging, packaging protection, etc., can solve the problems of potential safety hazards, large packaging machine body, inconvenient handling, etc., and achieve the effects of easy promotion, high work efficiency, and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

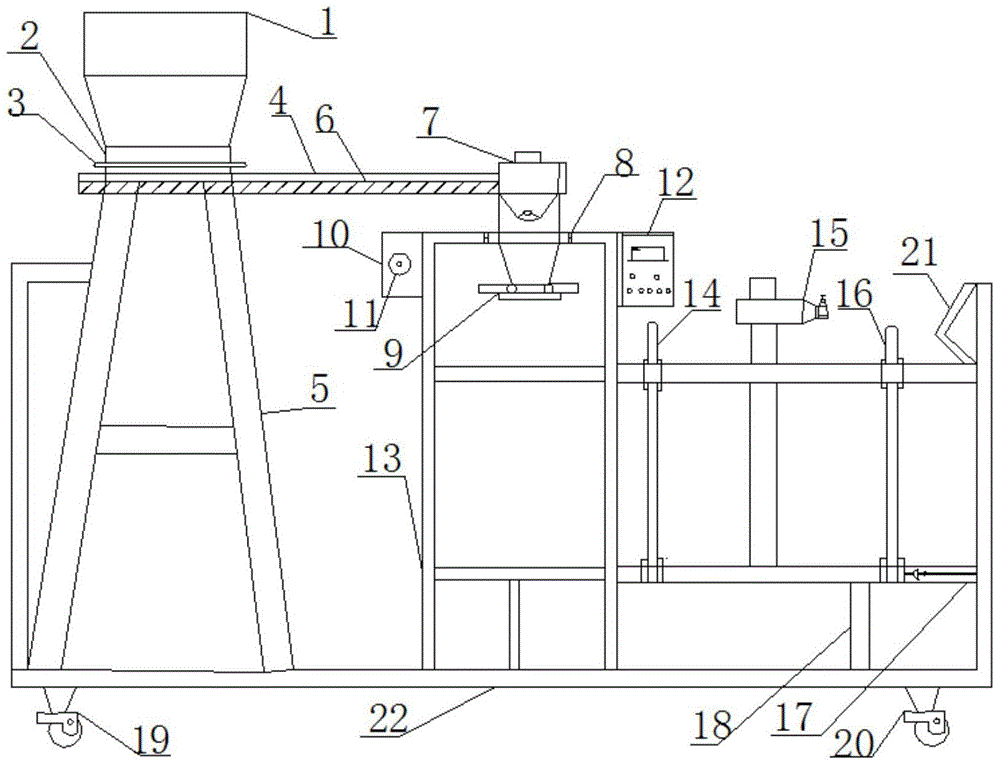

[0023] Such as figure 1 A packaging machine as shown, including a preparation hopper 1, a discharge port 2, an inspection gate 3, a feeder 4, a feeder bracket 5, a discharger 6, a cutting device 7, an electromagnetic connection box 10, and an electrical control Cabinet 12, weighing entrainment device 9, sewing machine 15, belt conveyor 17 and steel structure support 13, the lower part of the preparation hopper 1 is fixedly connected with the feeding port 2, and the middle part of the feeding port 2 is provided with an inspection gate 3, and the feeding port 2. A feeder 4 is provided below the feeder 4. A discharge machine 6 is fixedly connected to the bottom of the feeder 4. A feeder support 5 is provided below the discharge machine 6. A cutting device 7 is provided at the right end of the feeder 4 and the discharge machine 6. A weighing entrainment device 9 is fixedly connected to the bottom of the cutting device 7, and a steel structure support 13 is fixedly connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com