Improved integrated oxidation ditch

An oxidation ditch, an improved technology, applied in chemical instruments and methods, aerobic and anaerobic process treatment, water/sludge/sewage treatment, etc., can solve the problems of low oxygenation power efficiency, small water depth of oxidation ditch, and land occupation Large area and other problems, to achieve stable treatment effect, stable effluent water quality, and reduce the occupied area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

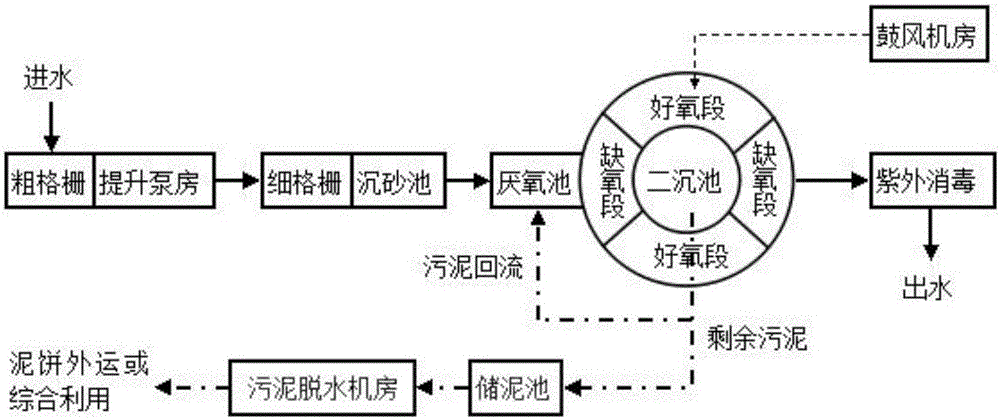

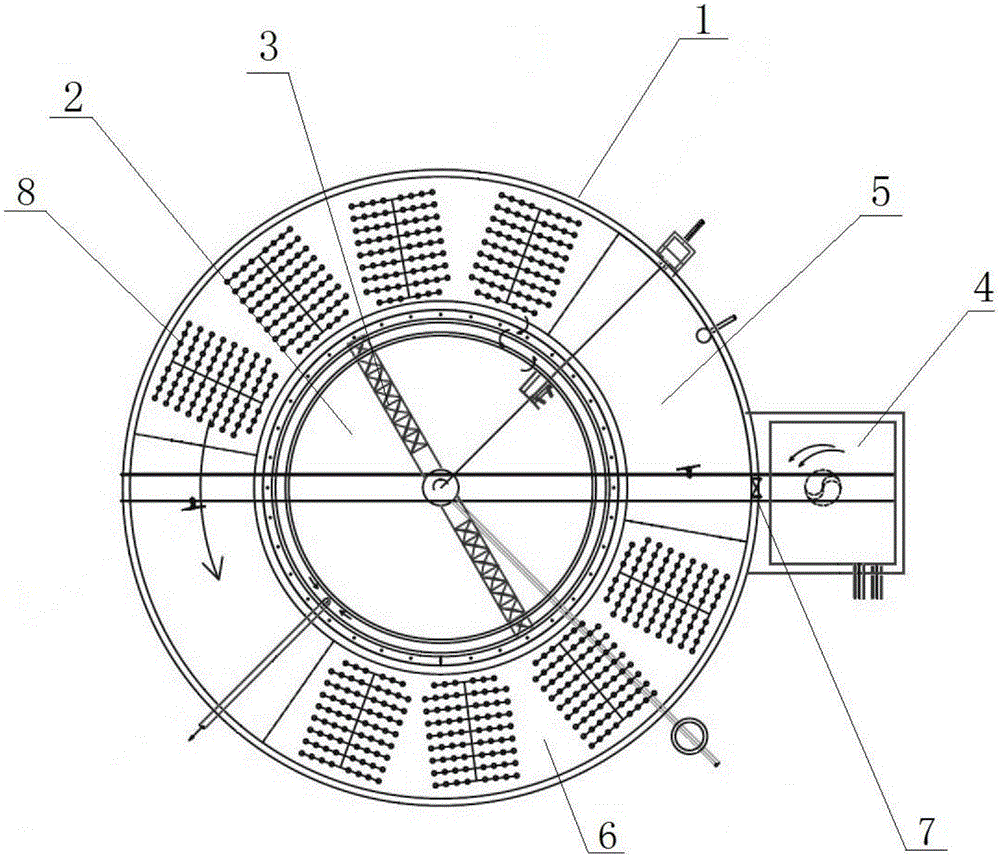

[0019] Zhenxiong County Sewage Treatment Plant, Zhaotong City, Yunnan Province: The construction scale is 25,000 m in the near future 3 / d, the main process of the sewage treatment plant adopts an improved integrated oxidation ditch process of the present invention such as figure 1 As shown, the hydraulic retention time of the biochemical reaction section is 11.5h, of which the anaerobic zone is 1.5h, the anoxic zone is 2.5h, and the aerobic zone is 7.5h. Dimensions of the integrated oxidation ditch: Φ48.0m×5.6m (two), the effective volume of the single-tank biochemical reaction section is 5270m 3 , the effective water depth is 5m, the ditch width is 9m, and the size of the secondary settling tank located in the center of the integrated oxidation ditch: Φ30.0m×4.7m. Design sludge concentration MLSS=4000mg / L, sludge load is 0.053kgBOD 5 / (kgMLSS·d), the sludge return ratio is 100%.

[0020] The wastewater treatment plant is designed to have influent BOD of 100mg / L, COD of 22...

Embodiment 2

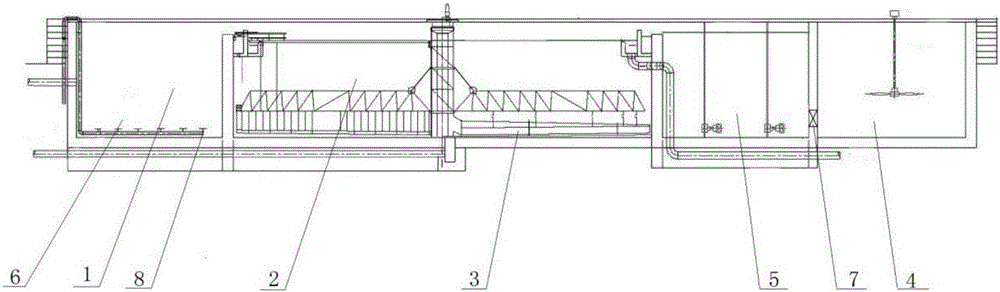

[0024] Embodiment 2: as Figure 1 ~ Figure 3 As shown, an improved integrated oxidation ditch management device includes an oxidation ditch, a secondary settling tank, and a single-pipe dredger 3. The single-pipe dredger 3 is built in the bottom of the secondary settling tank, and the oxidation ditch is distributed in a ring shape. Around the ring-shaped secondary sedimentation tank, the oxidation ditch includes an anaerobic tank, anoxic section 5, and aerobic section 6. The oxidation ditch and the secondary sedimentation tank are connected to each other, and the water from the inner circle of the oxidation ditch enters the secondary sedimentation tank, and the secondary sedimentation tank The bottom sludge is discharged through the single-pipe suction dredger 3, which combines the dual flow characteristics of push flow and complete mixing. The mixed liquid of sewage and activated sludge circulates in the oxidation ditch, which makes the oxidation ditch in the direction of wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com