Organic-silicon-resin-base superhydrophobic oil-absorbing sponge and preparation method thereof

An oil-absorbing sponge and organosilicon technology, applied in the field of oil-absorbing sponges, can solve the problems of crude oil treatment that does not greatly improve the oil absorption performance, cannot meet the requirements of use, and cannot leak.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

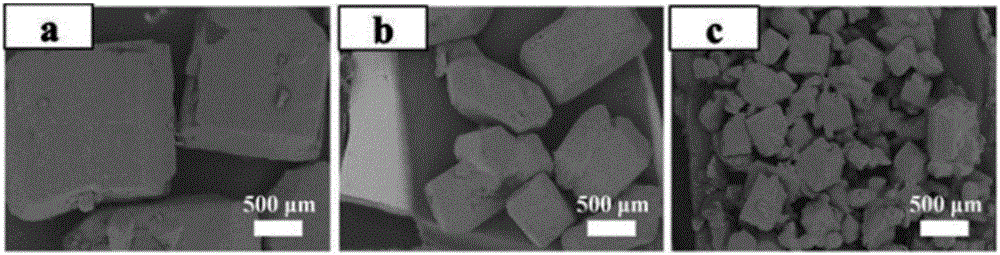

Image

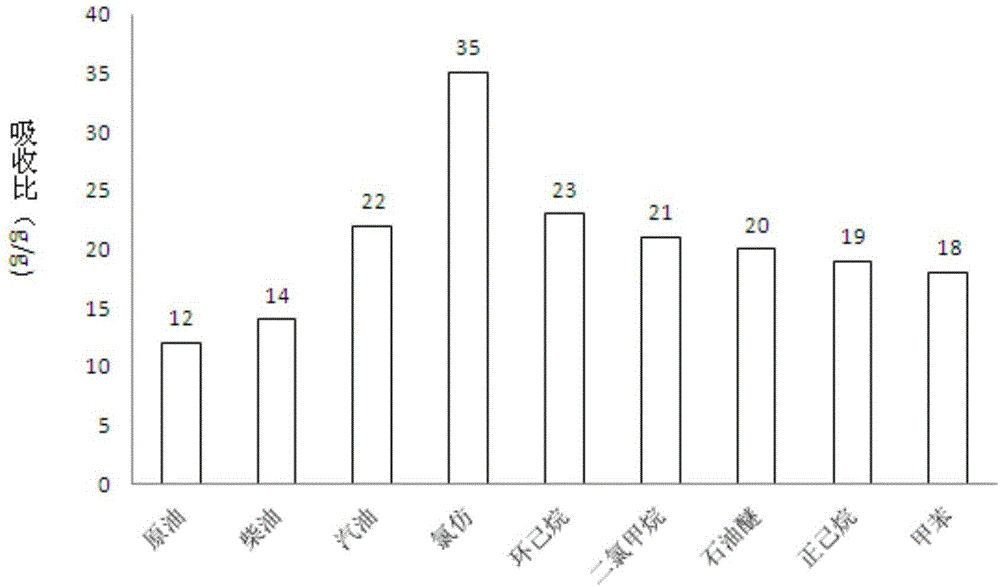

Examples

Embodiment 1

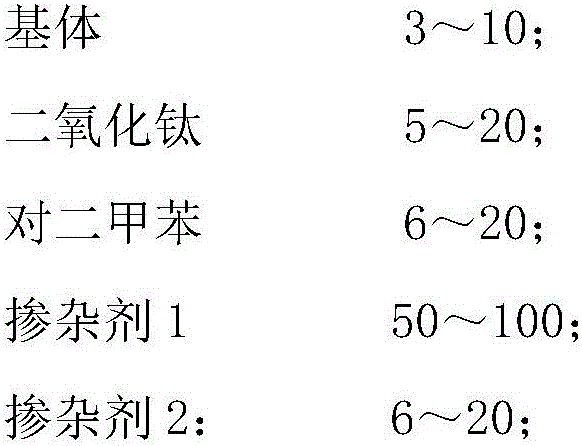

[0025] 1. Mix the raw materials evenly and centrifuge, the specific formula is:

[0026]

[0027] 2. After removing the supernatant, put the mixture into an oven, heat to 70° C. and keep it warm for 12 hours.

[0028] 3. Wash the sample with water and acetone and dry it to obtain a superhydrophobic oil-absorbing sponge, and test it.

Embodiment 2

[0030] 1. Mix the raw materials evenly and centrifuge, the specific formula is:

[0031]

[0032] 2. After removing the supernatant, put the mixture into an oven, heat to 70° C. and keep it warm for 12 hours.

[0033] 3. Wash the sample with water and acetone and dry it to obtain a superhydrophobic oil-absorbing sponge, and test it.

Embodiment 3

[0035] 1. Mix the raw materials evenly and centrifuge, the specific formula is:

[0036]

[0037] 2. After removing the supernatant, put the mixture into an oven, heat to 70° C. and keep it warm for 12 hours.

[0038] 3. Wash the sample with water and acetone and dry it to obtain a superhydrophobic oil-absorbing sponge, and test it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com