Coating with three functions of stray light elimination, molecular adsorption and thermal control as well as preparation method and application of coating

A technology of molecular adsorption and stray light elimination, applied in coatings and other directions, can solve the problems of poor molecular adsorption effect, general coating binding force, inability to improve coating adsorption capacity, etc., and achieve the effect of simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

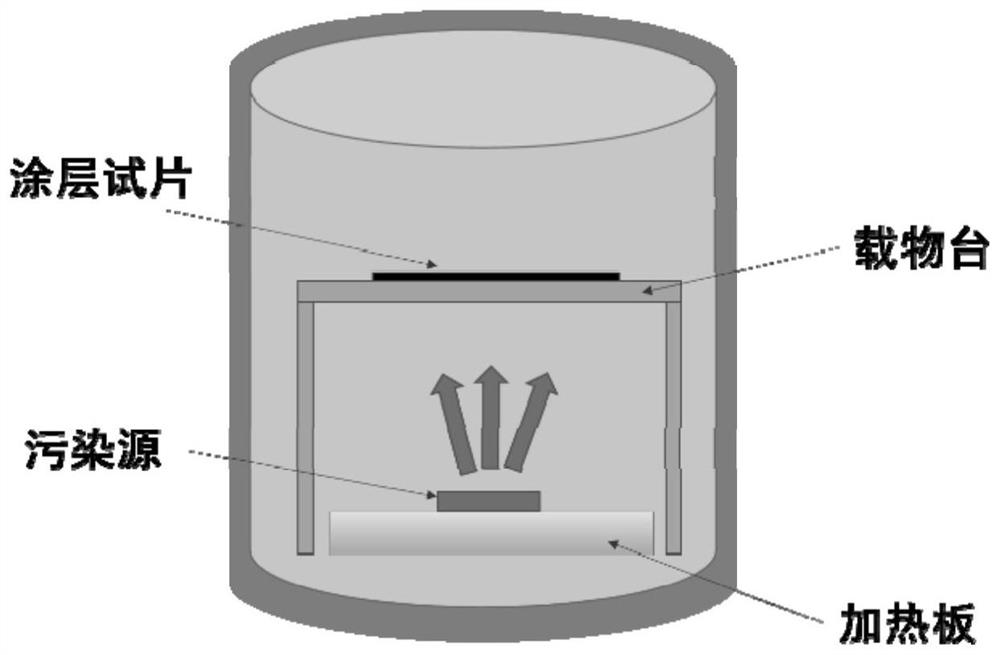

[0031] The invention overcomes the deficiencies of the prior art, and proposes a three-functional inorganic coating of stray light elimination-molecular adsorption-heat control, its preparation method and related applications. The coating first prepares a black slurry by ball milling and stirring, and then prepares an inorganic coating with three functions of stray light elimination-molecular adsorption-heat control by adding zeolite molecular sieve into the black slurry. Concrete preparation method and spraying method step include:

[0032] (1) Add carbon black into a ball-milling ceramic jar, add aluminum dihydrogen phosphate, and add an appropriate amount of deionized water for dilution, add a certain amount of ball-milling beads, and adopt a ball-milling method to obtain a black slurry.

[0033] (2) Transfer the black slurry to a beaker, add a certain amount of zeolite molecular sieve, and add an appropriate amount of deionized water, and stir evenly to obtain the coating. ...

Embodiment 1

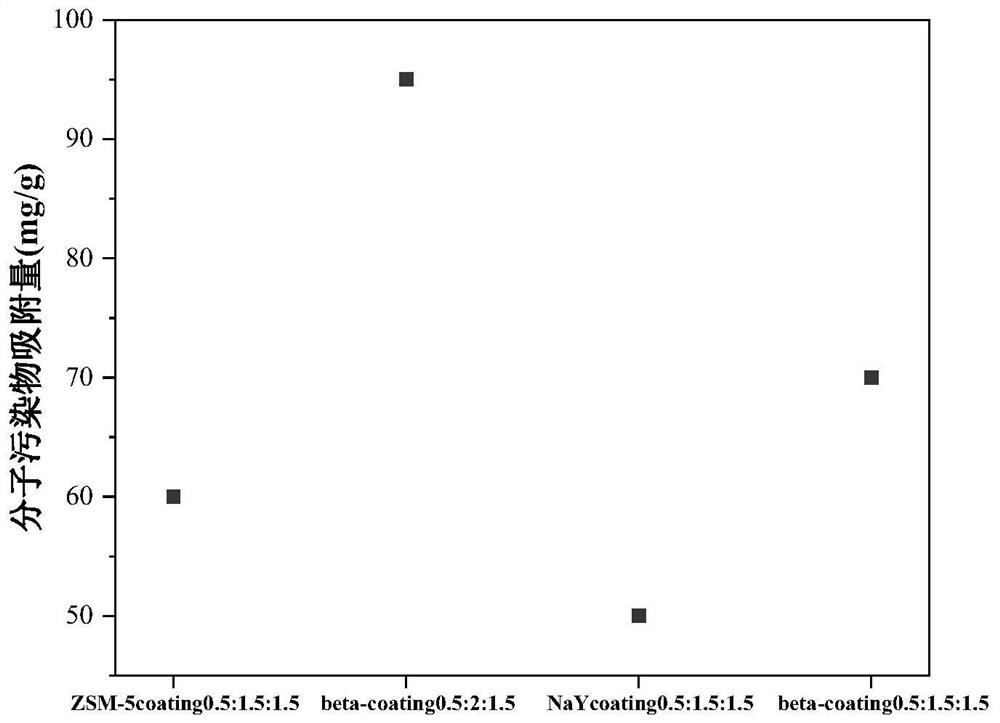

[0048] Embodiment 1: ZSM-5 zeolite molecular sieve prepares coating and sprays substrate coating

[0049] (1) Add 6g of carbon black into a ball-milling ceramic pot, add 45g of aluminum dihydrogen phosphate (40% solid content), and add 30g of deionized water to dilute, add 300g of ball-milling beads, and use ball milling to obtain black slurry.

[0050] (2) Transfer the black slurry to a beaker, add 18g of ZSM-5 zeolite molecular sieve, and add 15g of deionized water, and stir evenly to obtain the coating.

[0051] (3) Sandblasting the aluminum substrate.

[0052] (4) Molecular absorption paint is sprayed on the substrate after sandblasting.

[0053] (5) Dry the sprayed paint to obtain ZSM-5 stray light elimination-molecular adsorption-thermal control three-functional inorganic coating (ZSM-5coating0.5:1.5:1.5, the ratio is carbon black, molecular sieve and dihydrogen phosphate Aluminum (in terms of solid content) mass ratio).

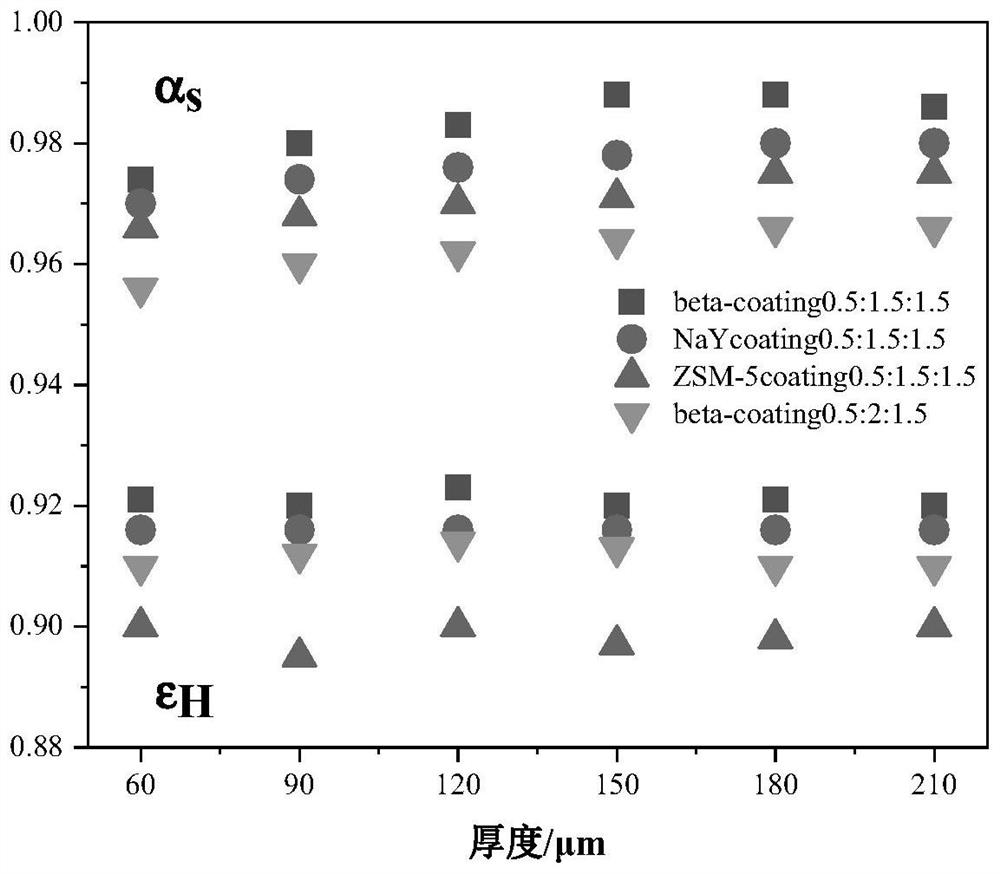

[0054] Specific technical indicators of the ...

Embodiment 2

[0055] Embodiment 2: beta zeolite molecular sieve prepares coating and sprays substrate coating

[0056] (1) The carbon black of 9g is added in the ceramic pot of ball milling, adds in 67.5g aluminum dihydrogen phosphate (40% solid content), and adds 50g deionized water and dilutes, adds the ball milling bead of 450g, adopts the mode of ball milling, obtains black paste.

[0057] (2) Transfer the black slurry to a beaker, add 36g of beta molecular sieve, and add 20g of deionized water, stir evenly to obtain the coating.

[0058] (3) Sandblasting the aluminum substrate.

[0059] (4) Spraying the paint on the sandblasting substrate.

[0060] (5) Dry the sprayed coating to obtain beta stray light elimination-molecular adsorption-thermal control three-functional inorganic coating (beta-coating0.5:2:1.5, the ratio is carbon black, molecular sieve and aluminum dihydrogen phosphate ( In terms of solid content) mass ratio).

[0061] The specific technical indicators of the beta st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com