Vacuum collector tube and process for preparing coating thereof

A vacuum heat collector tube and absorption layer technology, applied in metal material coating process, coating, vacuum evaporation coating and other directions, can solve the problems of easy aging, poor thermal insulation performance, high emissivity, and achieve good electrical and thermal conductivity, anti- The effect of improving the degree of aging and improving the heat absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

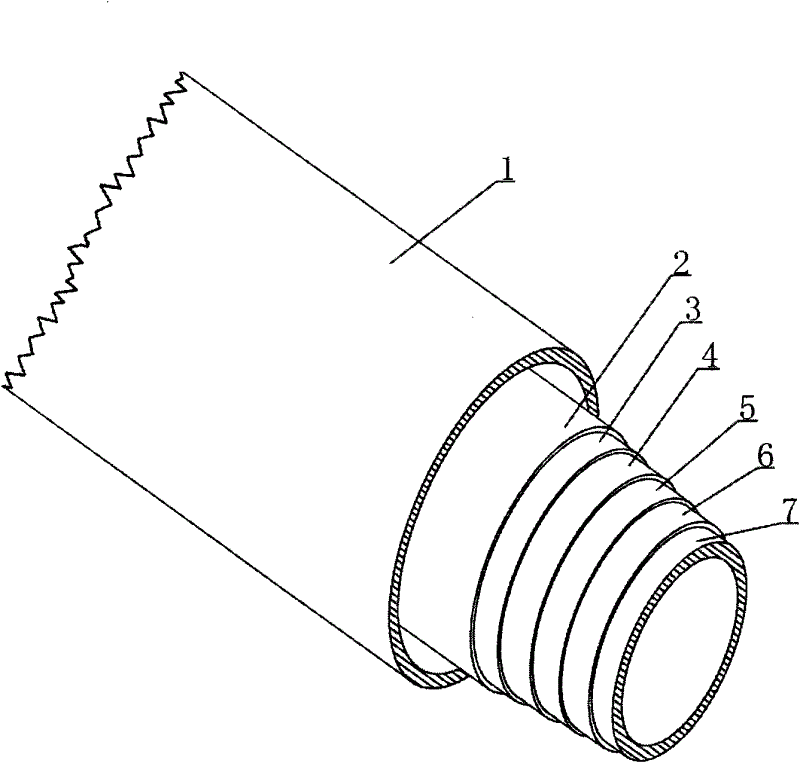

[0027] 1), put the cleaned glass inner tube 7 into the magnetron sputtering chamber;

[0028] 2) Vacuumize the magnetron sputtering chamber to 5.0E-3Pa;

[0029] 3), turn on the argon and nitrogen flowmeters, fill the magnetron sputtering chamber with high-purity nitrogen and argon, start the power supply of the aluminum target, sputter for 1 minute and 20 seconds, and coat a layer of AlN-Al on the outer surface of the glass inner tube 7 Adhesive layer 6;

[0030] 4), turn off the nitrogen gas flow meter, start the copper target power supply, sputter for 6 minutes, and coat a layer of pure copper high infrared reflection layer 5;

[0031] 5), stop the power supply of the copper target, turn on the nitrogen gas flowmeter, start the power supply of the aluminum target and the titanium target, sputter for 4 minutes and 30 seconds, and coat a layer of AlN-Ti high metal absorption layer 4;

[0032] 6) Reduce the titanium target current, change the nitrogen flow rate, sputter for ...

Embodiment 2

[0035] The other steps are the same as in the first embodiment, step 2) the magnetron sputtering chamber is evacuated to 3Pa, and the above-mentioned vacuum heat collecting tube coating structure can also be manufactured.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com