Preparation method of capacitor roughened film capable of long-term operation on UHV power grid

A high-voltage power grid and thin-film preparation technology, which is applied in the direction of fixed capacitor dielectric and fixed capacitor parts, can solve the problems of increasing product performance, product film rupture, and high scrap rate, so as to prevent dielectric loss, ensure utilization rate, good extrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

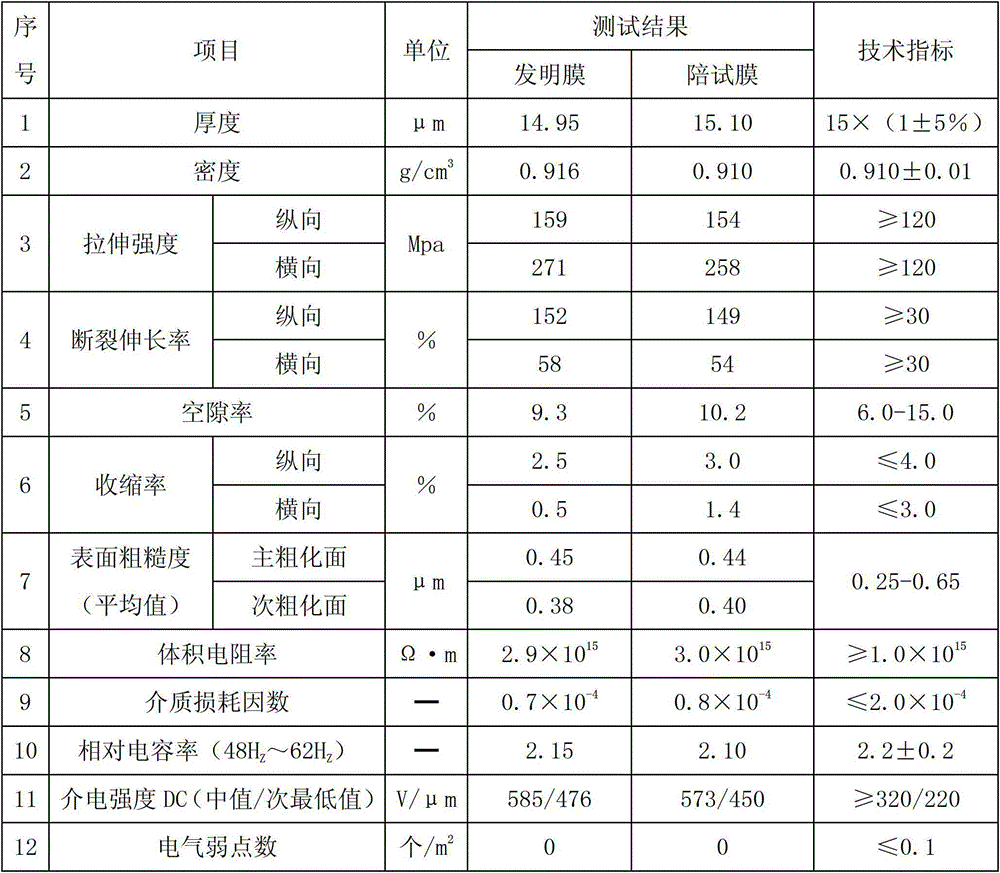

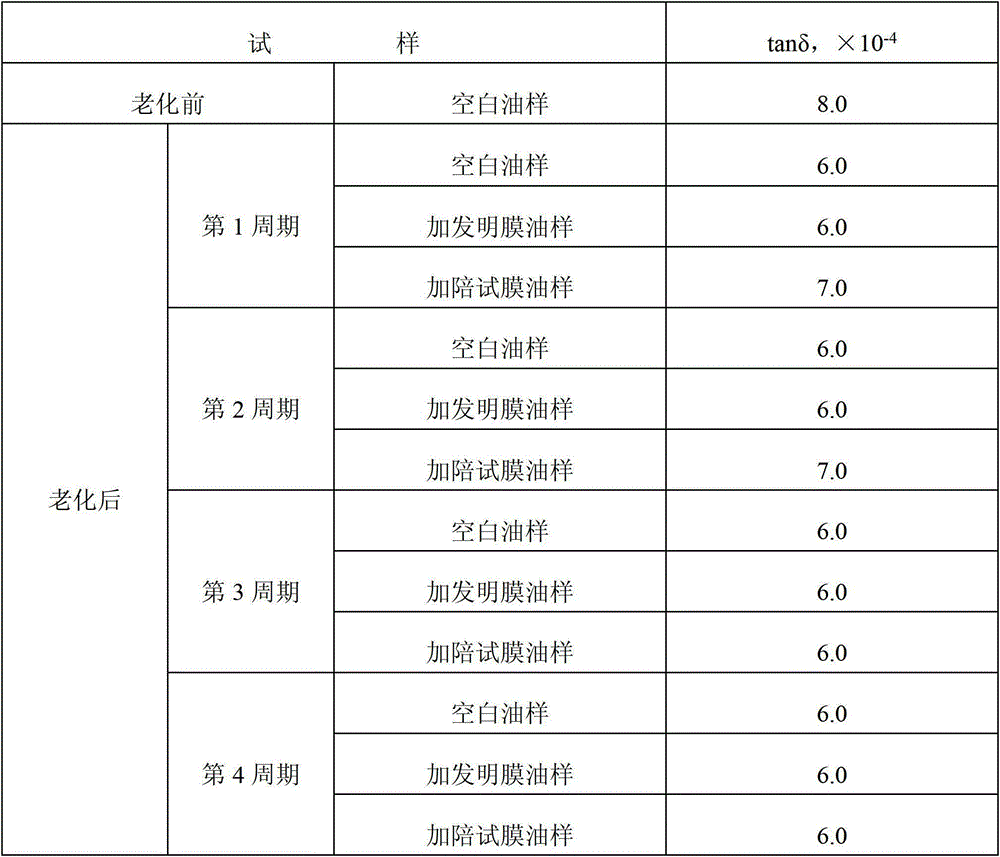

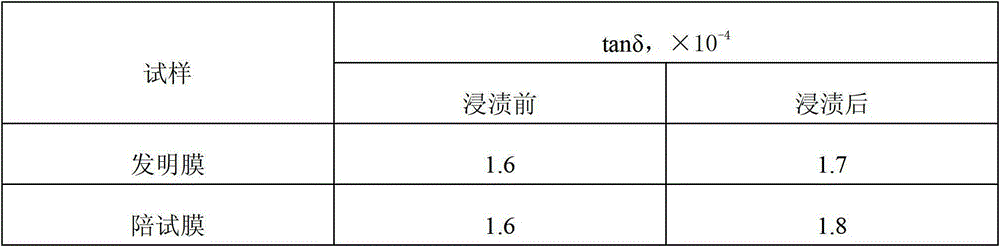

Examples

Embodiment Construction

[0018] The following specific embodiments are further descriptions of the present invention, but the present invention is not limited to the following specific embodiments.

[0019] A method for preparing a roughened film for a capacitor capable of long-term operation on an ultra-high voltage power grid, comprising the following steps,

[0020] (1) Raw material and production conditions: raw material polypropylene granules, with isotacticity ≥ 97.5%, melt index 3.2-3.4g / 10min, molecular weight distribution coefficient Mw / Mn less than 10 and greater than 5, internal heat-resistant antioxidant The melting point is 220-250°C and the content is 800-1100ppm; the environment in the first process hood of the production equipment requires a temperature of 32-36°C, a humidity of 30%-70%, and a cleanliness level of 10,000 or 10,000 Below the second process hood, the environment requires a temperature of 20-30°C, a humidity of 50%-60%, and a cleanliness level of 10,000 or less; the isota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com