Air curtain protection method for bath wall of melting furnace

A protection method and melting furnace technology, applied in furnace safety devices, crucible furnaces, furnaces, etc., can solve problems such as energy loss, heat loss, and erosion of pool bricks, and achieve the effect of reducing heat loss and improving service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

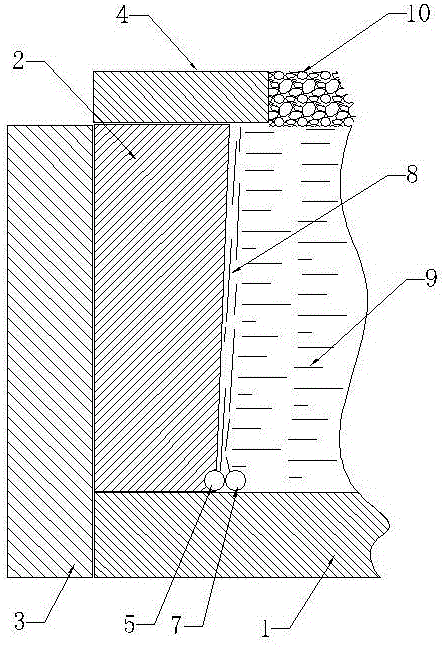

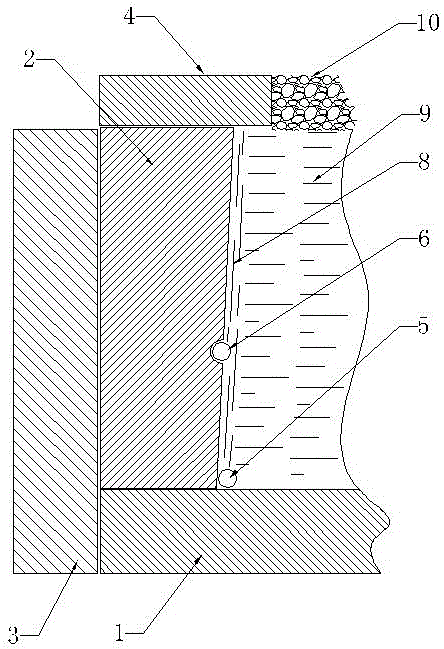

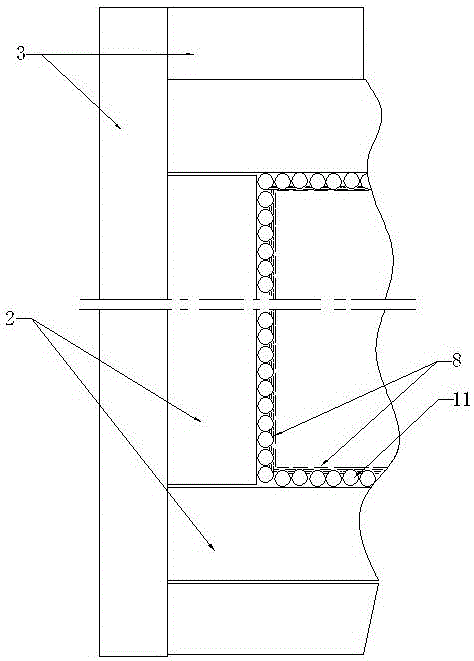

[0018] figure 1 Among them, the air supply pipes (5) and (6) used to make the isolation air curtain (8) are laid flat on the bottom of the inner side of the furnace pool wall brick (2), and the groove at a certain height inside the melting furnace pool wall brick Inside. The gas is ejected through one or several rows of ventilation slits or ventilation holes on the pipe wall, and a layer of isolation air curtain (8) is created between the inner surface of the furnace wall brick (2) and the melt (9), The furnace pool wall brick (2) is isolated from the melt (9) to reduce or prevent the melt (9) from contacting and eroding the furnace pool wall brick (2). In order to ensure that the above-mentioned isolation air curtain (8) is always attached to the refractory surface of the melting furnace pool wall, the upper end of the inner surface of the melting furnace pool wall can be inclined at an angle to the inner side of the kiln pool. The gas supply pipes (5) and (6) laid flat abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com