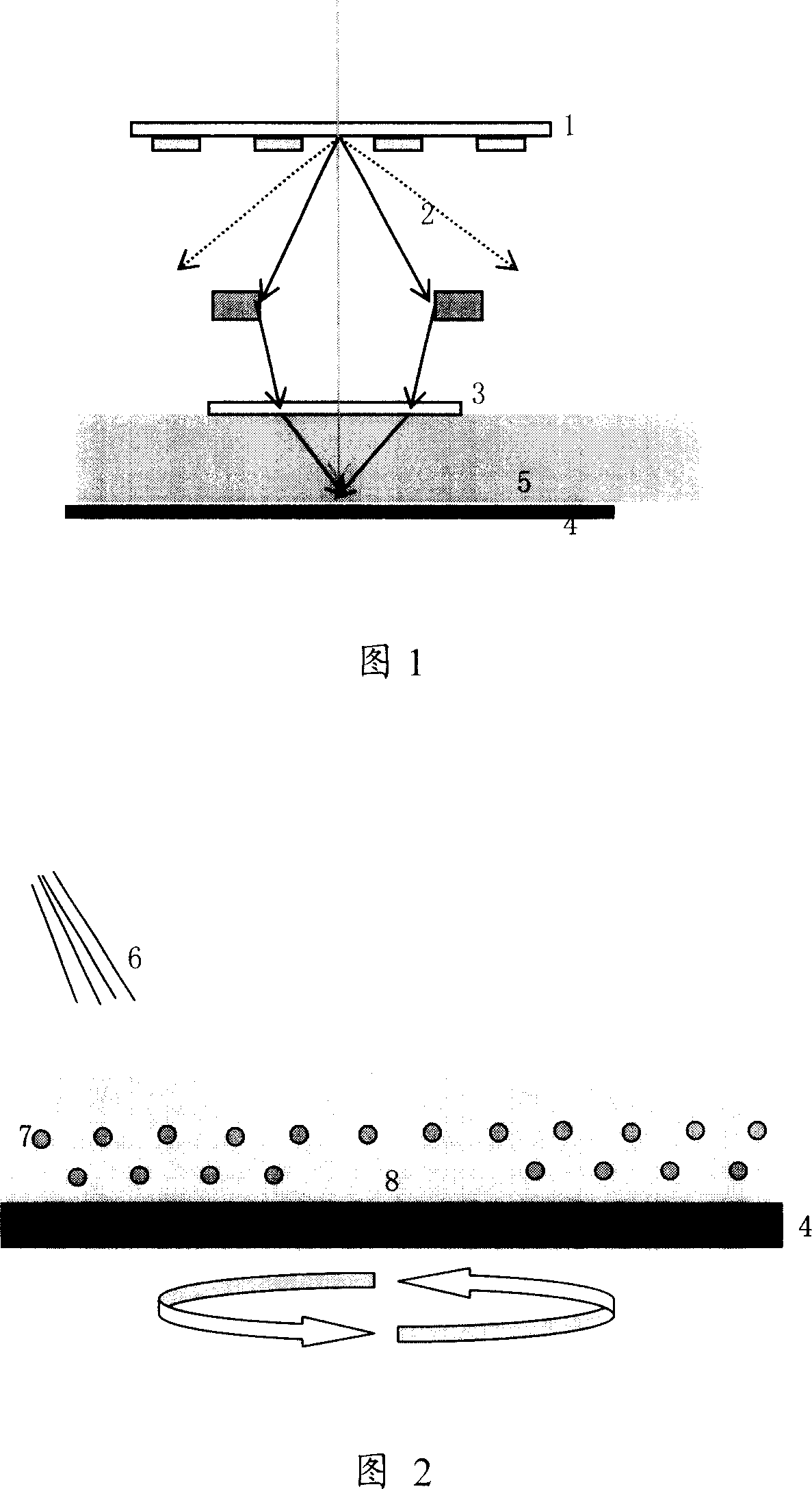

Method for reducing water pollution of optical elements in immersion type photoengraving technology

A technology of immersion lithography and optical components, applied in the direction of microlithography exposure equipment, optical, electrical components, etc., can solve the problems of reducing expressiveness and eroding optical components, and achieve the effect of protection from erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method to reduce the contamination of optical components by aqueous solution in immersion lithography technology. First, the silicon wafer enters the glue coating equipment and coats the photosensitive material. The photosensitive material includes ketones or ethers or alkane organic solvents, photosensitive crosslinking resins, photoacid generators and trace metal ions, the molecular weight is between 85000 and 150000, the organic solvent and photosensitive crosslinking resins and photoacid generators The molar ratio is 1:X:Y, wherein X and Y are 5-100, for example, the ratio is set as 1:20:50, 1:40:100, etc. Each coating dose is 1.5ml, 2ml, 3ml, 4ml or 5ml; each baking temperature is 60°C, 100°C, 120°C, 150°C or 250°C, and the baking time is 10 seconds, 30 seconds, 50 seconds, 80 seconds or 120 seconds; the cooling temperature is 15°C, 20°C, 23°C or 25°C, and the cooling time is 20 seconds, 30 seconds, 40 seconds, 50 seconds or 60 seconds.

[0030] Next, rinse the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com