Rocker arm type valve wear test device

A wear test, rocker-type technology, applied in the direction of testing wear resistance, etc., can solve the problems of long inspection period, neglect, lack of pertinence, etc., and achieve the effect of avoiding too long test period, accurate research results and accurate contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

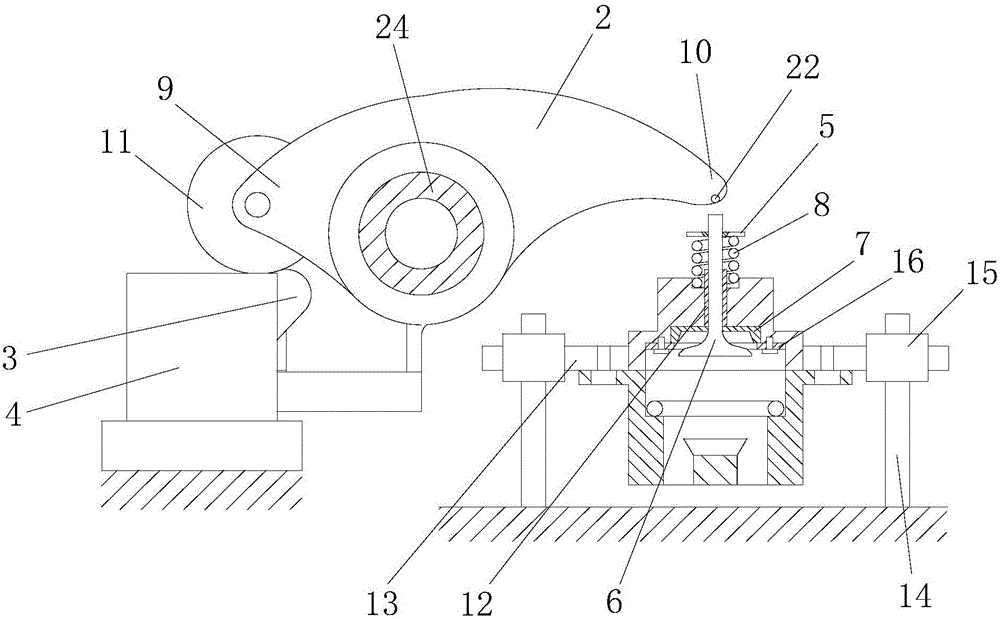

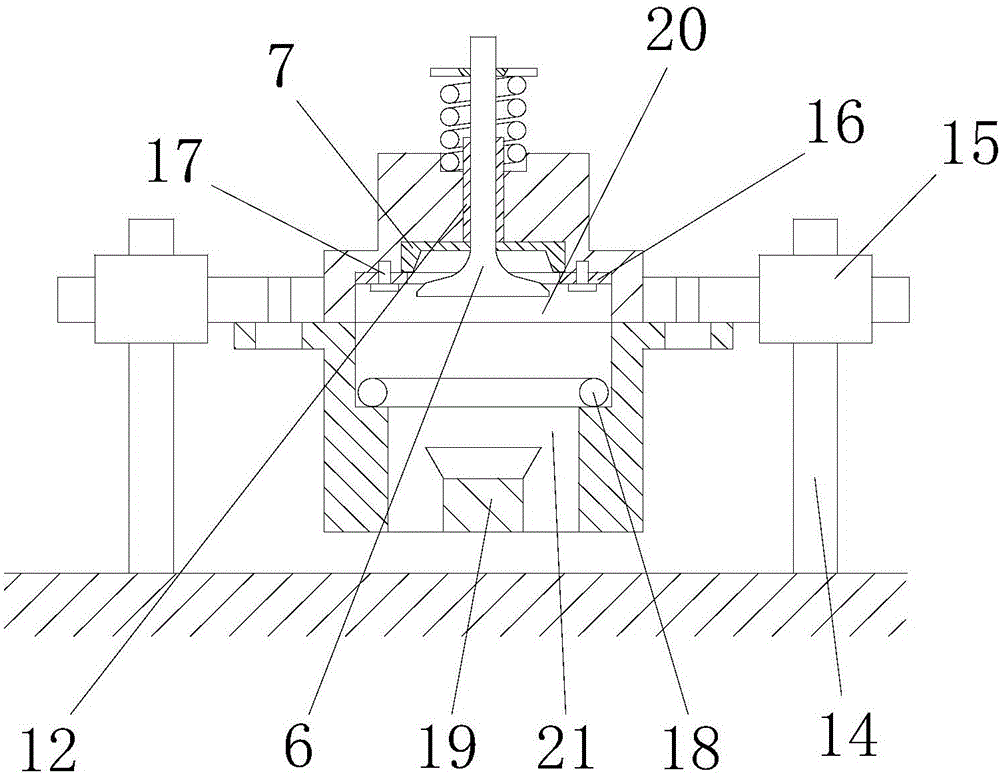

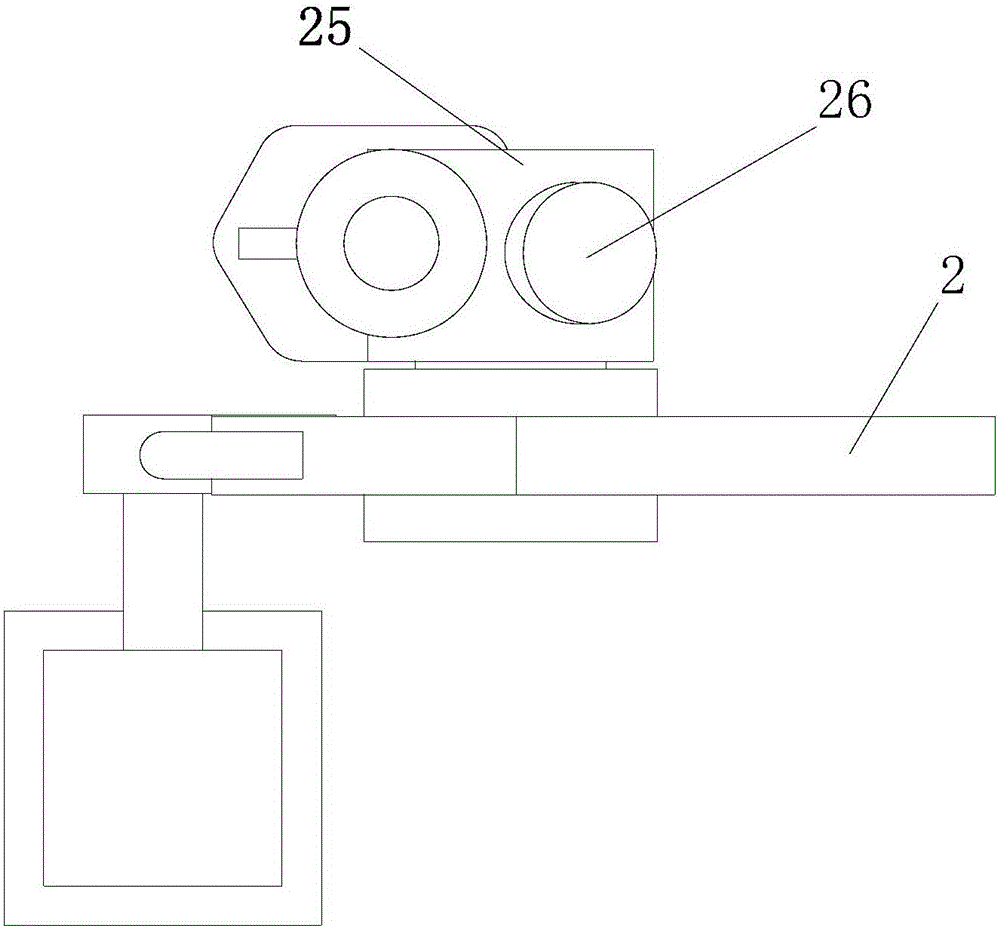

[0026] A rocker arm type valve wear test device, comprising a rocker arm platform 1, a rocker arm 2, a cam 3, a motor 4, a combustion chamber, a valve lock head 5, a valve 6, a valve seat ring 7 and driving the valve to the valve seat ring The impact spring 8, the valve head of the valve extends into the combustion chamber, the valve seat is arranged in the combustion chamber, the valve seat is set corresponding to the valve head of the valve, the valve stem of the valve protrudes from the combustion chamber, and the valve lock head is fixed Connected to the valve stem, the impact spring is set on the valve stem, the two ends of the impact spring are respectively connected with the valve lock head and the combustion chamber, the middle part of the rocker arm is hinged on the rocker arm platform, and one end of the rocker arm is the driving end 9 driven by a cam. The other end of the rocker arm is the trigger end 10 for driving the valve stem to move, and the motor is used to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com