Grounding module and preparation method thereof

A technology of grounding modules and metal poles, applied in the direction of connection, connection contact materials, electrical components, etc., can solve the problems of large footprint, unstable resistance, easy corrosion, etc., and achieve easy operation, reduce grounding resistance, and cost cheap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A grounding module, which is composed of an external non-metallic conductive material wrapped with a built-in metal pole core. In terms of weight percentage, the external non-metallic conductive material consists of 15% artificial graphite powder, 50% natural phosphorus flake graphite and 35% high-grade Composed of conductive cement, the built-in metal grounding body is φ18 galvanized rebar.

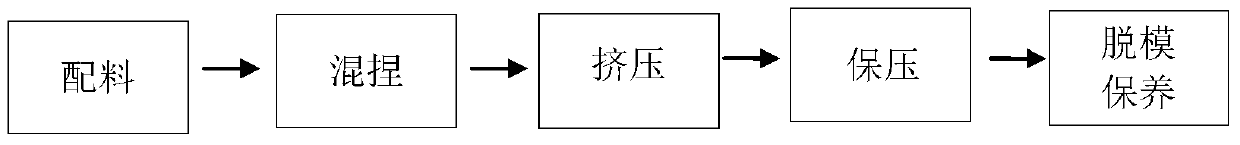

[0032] The grounding module can be prepared by conventional preparation methods, for example, including the following steps:

[0033] (1) Ingredients: weighed according to the weight ratio, artificial graphite powder with a particle size of less than 0.5mm: 15%, natural phosphorus flake graphite with a mesh number of 50: 50%, 525# high-grade cement: 35%;

[0034] (2) Kneading: Put the artificial graphite powder, natural flake graphite and high-grade cement in the ingredients into the kneading pot, add a certain amount of water, and stir for 40 minutes to make it fully kneaded even...

Embodiment 2

[0038] A grounding module, which is composed of an external non-metallic conductive material wrapped with a built-in metal pole core. In terms of weight percentage, the external non-metallic conductive material consists of 10% artificial graphite powder, 60% natural phosphor flake graphite and 40% high-grade conductive Composed of cement, the built-in metal grounding body is φ18 galvanized rebar.

[0039] The grounding module can be prepared by conventional preparation methods, for example, including the following steps:

[0040] (1) Ingredients: weighed according to the weight ratio, artificial graphite powder with a particle size of less than 0.5mm: 10%, natural phosphorus flake graphite with a mesh size of 50: 60%, 525# high-grade cement: 40%;

[0041] (2) Kneading: Put the artificial graphite powder, natural flake graphite and high-grade cement in the ingredients into the kneading pot, add a certain amount of water, and stir for 40 minutes to make it fully kneaded evenly; ...

Embodiment 3

[0045] This embodiment also provides a grounding module with a specification of ¢150*800 as in Example 1. The difference is that the grounding module is prepared according to the preparation method described in the present invention. The specific preparation method includes the following steps:

[0046] (1) Ingredients: weighed according to weight ratio, artificial graphite powder with a particle size of less than 0.5mm: 15%, natural phosphorus flake graphite with a mesh size of 50: 50%, 525# high-grade cement: 35%.

[0047] (2) Kneading: Put the prepared artificial graphite powder and natural flake graphite into a kneading pot, add a certain amount of water, and stir for 25 minutes; then add high-grade cement in the ingredients and stir for 20 minutes to make it fully kneaded evenly.

[0048](3) Extrusion: use φ18 galvanized rebar as the metal pole core, put the kneaded raw materials into the mold, and vibrate for 5 minutes at a vibration frequency of 200HZ and an amplitude of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface area | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com