Tobacco ridging and mechanical fertilizer distribution device

A technology for separating fertilizers and tobacco, which is applied in fertilization devices, agricultural machinery and implements, fertilizer distributors, etc., can solve the problems of time-consuming and laborious, late blooming of tobacco plants, and more concentrated fertilizers in contact with moist soil, so as to improve fertilization. The uniformity, the effect of improving the release rate of fertilizer efficiency and improving the utilization rate of fertilizer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following is attached Figure 1-6 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

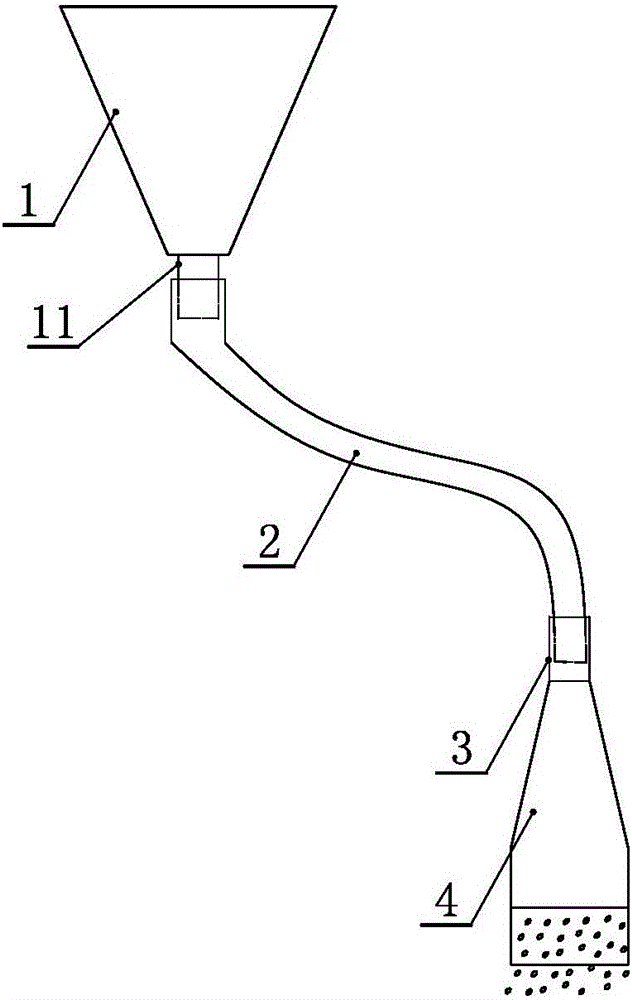

[0024] like figure 1 Shown, this invention mainly comprises fertilizer hopper 1, lower fertilizer pipe 2, connecting pipe 3 and fertilizer divider 4 four parts. The top opening of the fertilizer hopper 1 is convenient for adding fertilizer, and the bottom constriction 11 is convenient for the natural falling of fertilizer.

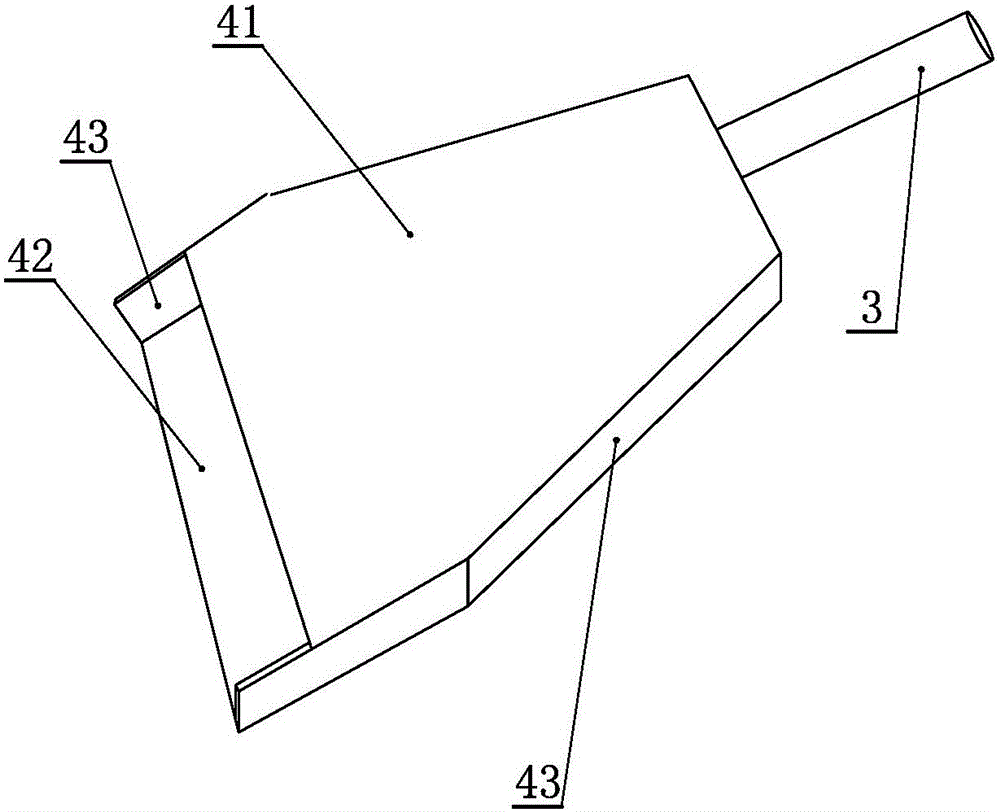

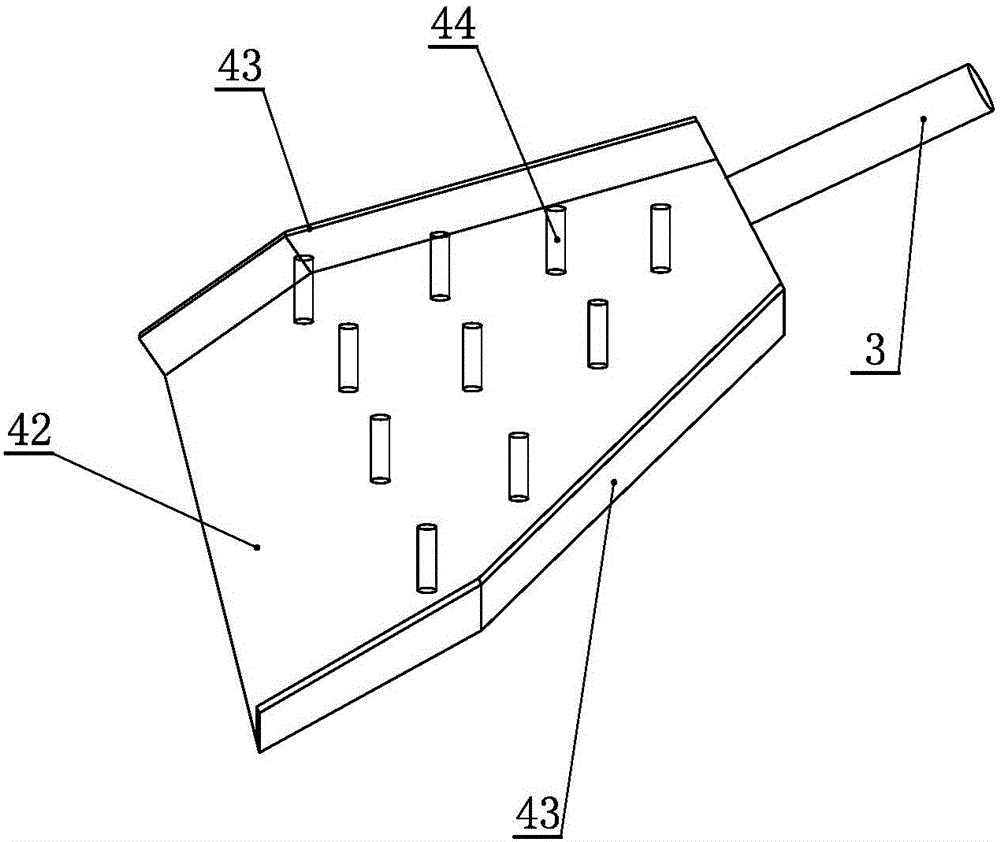

[0025] The bottom constriction 11 of the fertilizer hopper 1 communicates with one end of the lower fertilizer pipe 2 , and the other end of the lower fertilizer pipe 2 is connected with the fertilizer distributor 4 through the connecting pipe 3 . In order to adjust the arrangement of the lower fertilizer pipe 2 conveniently, the lower fertilizer pipe 2 adopts a plastic pipe. The lower fertilizer pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com