Ultrafine/nanocrystalline metal and short-process and large-deformation preparing method thereof

A nanocrystalline, short-process technology, applied in the field of metal processing, can solve the problems of product thickness limitation, long process, short process, etc., and achieve the effect of large plastic deformation in short process, good grain refinement and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

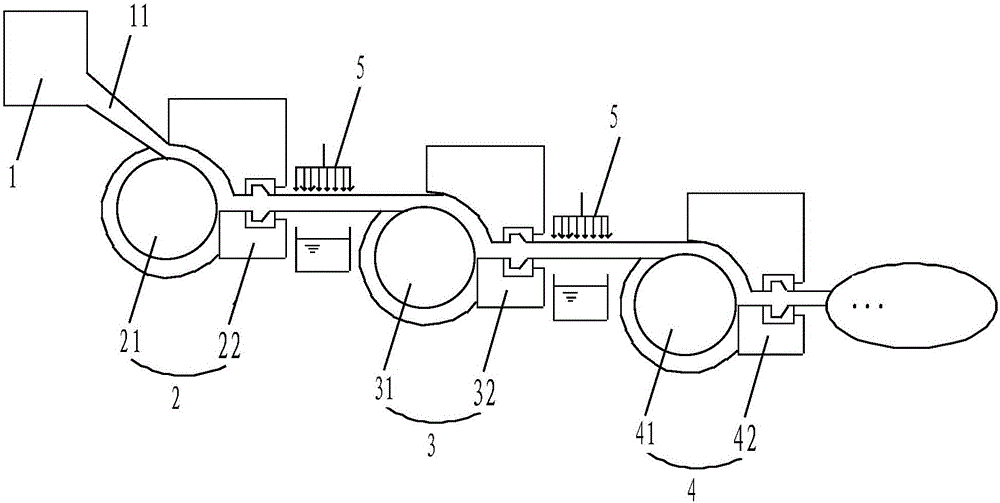

[0043] Adopt the method provided by the invention to prepare ultra-fine-grained aluminum alloy rod, take Al-0.5Si (wt.%) alloy as example:

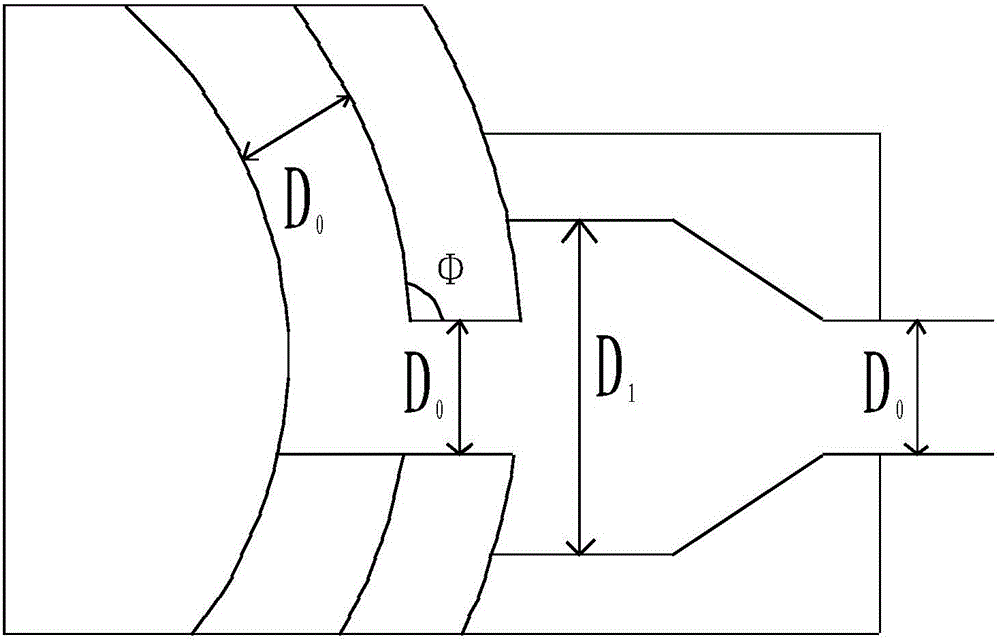

[0044] The extrusion shoe wrap angle of the continuous rheological extrusion machine is 90°, the rotation angle is 90°, and the extrusion die is an aluminum alloy extrusion die.

[0045] In the first step, according to the alloy composition, industrial pure aluminum and Al-9Si (wt.%) master alloy are used, the raw materials are melted in a certain order, the melt is degassed and slag removed at 800 ° C, and the melted alloy is melted The body is poured to the entrance of the rheological extruder, and the pouring temperature is 750 ° C, and the Al-0.5Si (wt.%) alloy raw material rod is prepared;

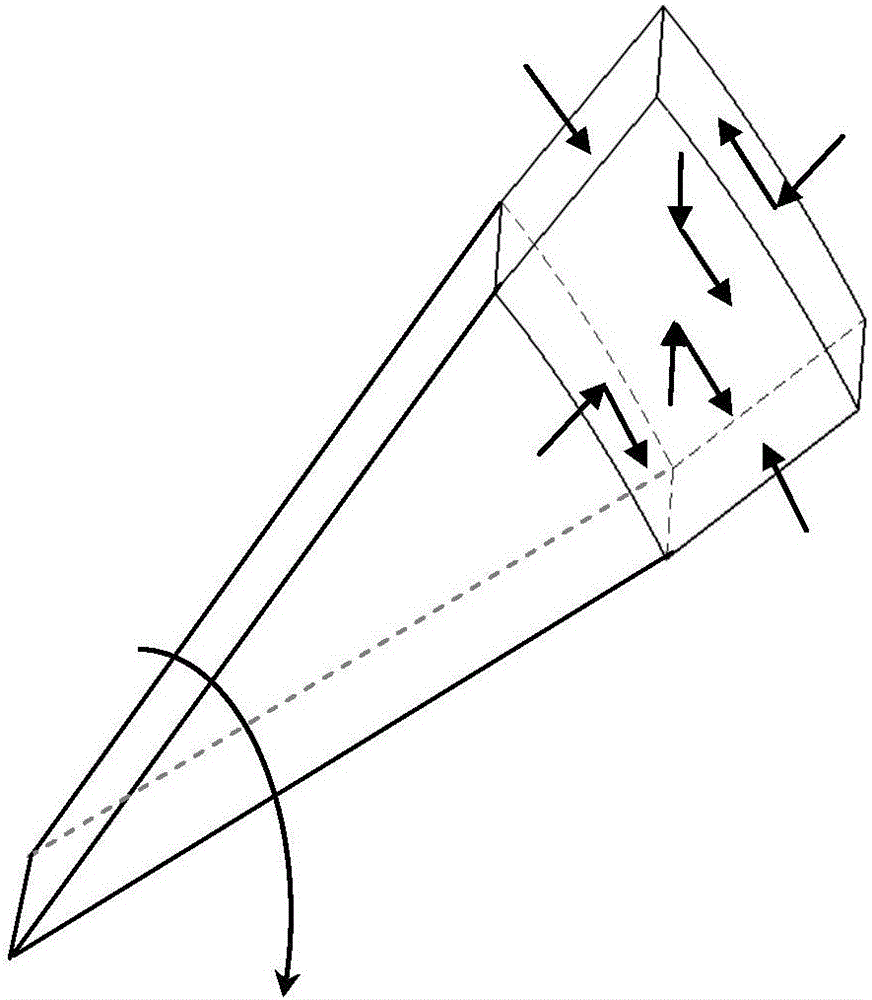

[0046] The second part starts the continuous rheological extruder, feeds the pretreated Al-0.5Si (wt.%) alloy raw material rod into the wheel groove of the continuous rheological extruder, and the metal rod rubs in the cavity Dynamic shear defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com