Automatic production system for bulb lamps with LED (light-emitting diode) filaments and product detecting method of system

A technology for LED filaments and production systems, applied in general control systems, control/regulation systems, and other manufacturing equipment/tools, etc., can solve problems such as filament deviation, complex process, drift, etc., to improve pass rate, stable production, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

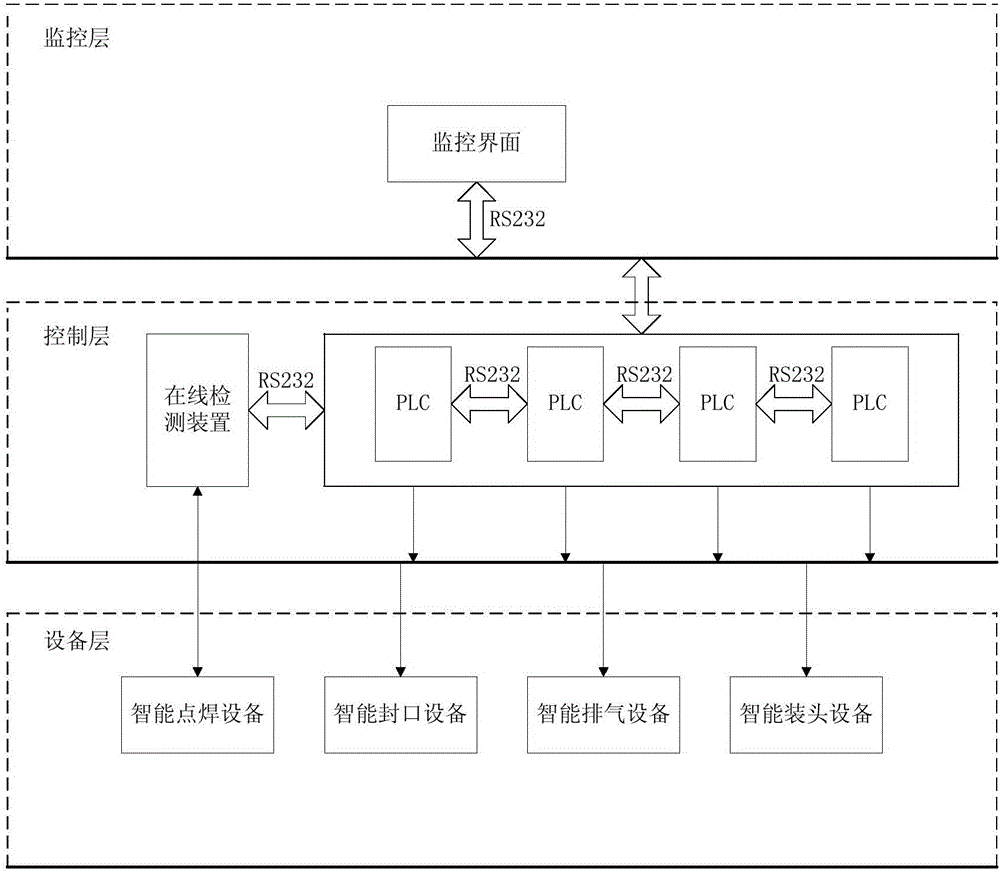

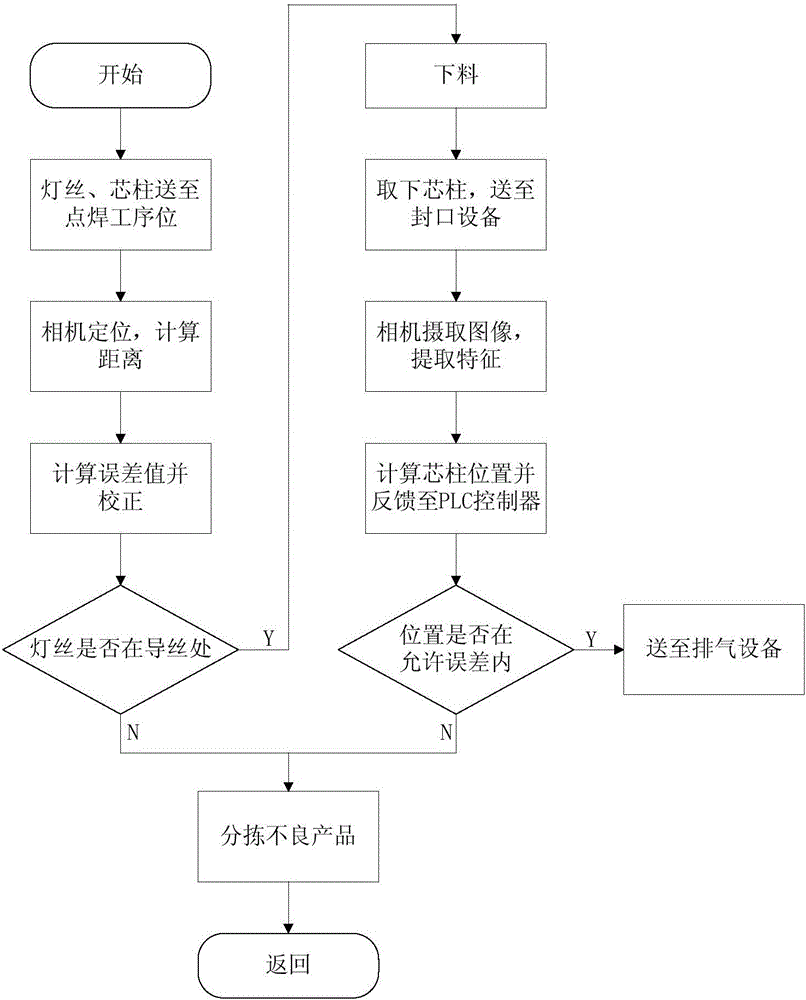

[0024] Such as figure 1 As shown, an automated production system for LED filament bulb lamps includes a monitoring layer, a control layer, and a device layer. The monitoring layer and the control layer are connected by a bus, and the control layer and the device layer are connected by a bus; The control layer includes several PLC controllers and online detection devices. The PLC controllers are connected through RS232 serial ports, and the PLC controllers and online detection devices communicate through RS232 serial ports; the monitoring layer adopts the RS232 protocol and the control layer PLC controller communication; the equipment layer includes: intelligent spot welding equipment, intelligent sealing equipment, intelligent exhaust equipment and intelligent head mounting equipment; the intelligent spot welding equipment, intelligent sealing equipment, intelligent exhaust equipment, intelligent head mounting equipment Connected in sequence; Intelligent spot welding equipment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com