Ultrapure water preparing system and adblue solution preparing system

A preparation system and ultra-pure water technology, which is applied to the preparation of urea derivatives, water treatment parameter control, and the preparation of organic compounds. The effect of small area and convenient discharge process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

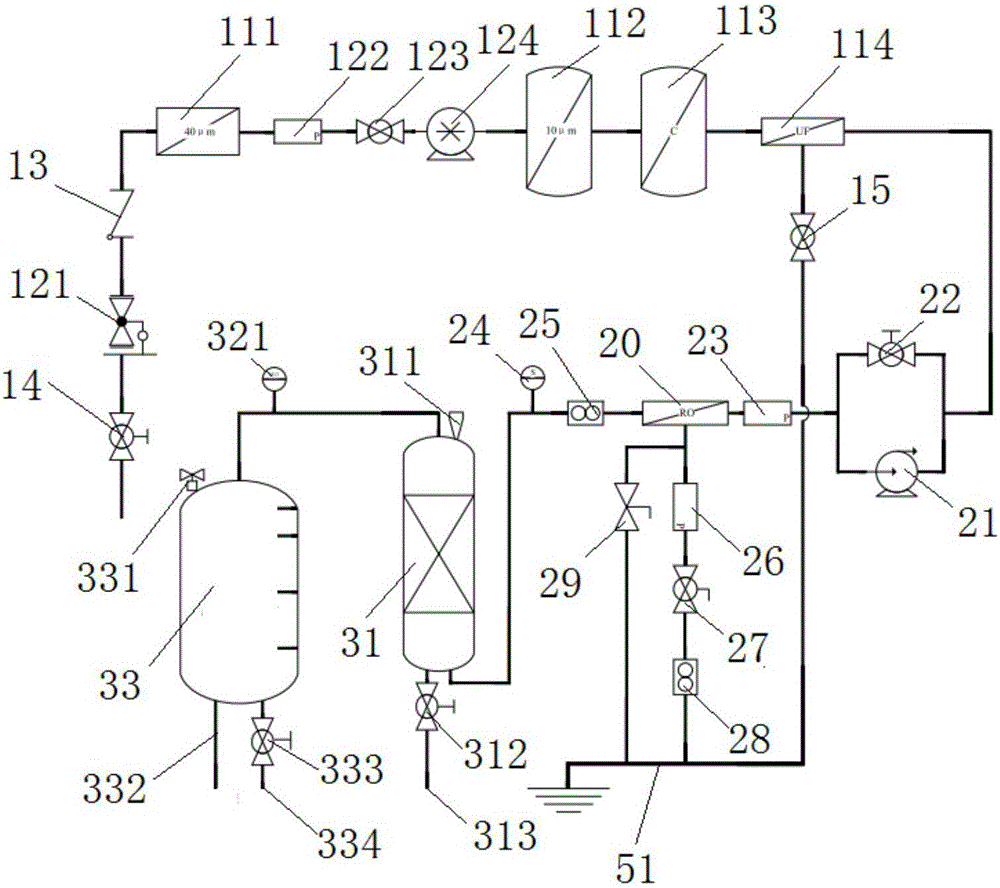

[0055] This embodiment provides an ultrapure water preparation system, which is mainly used in the production of urea solution for vehicles to prepare the ultrapure water required for the production of urea solution for vehicles. Specifically, the ultrapure water preparation system in this embodiment includes a pretreatment device, a reverse osmosis treatment device, and a polishing resin treatment device that are sequentially connected through pipelines.

[0056] Among them, the pretreatment device includes a filter component, which is used for preliminary filtration of the raw water to remove particles, residual chlorine, colloids and microorganisms in the raw water, and to protect the subsequent reverse osmosis treatment device.

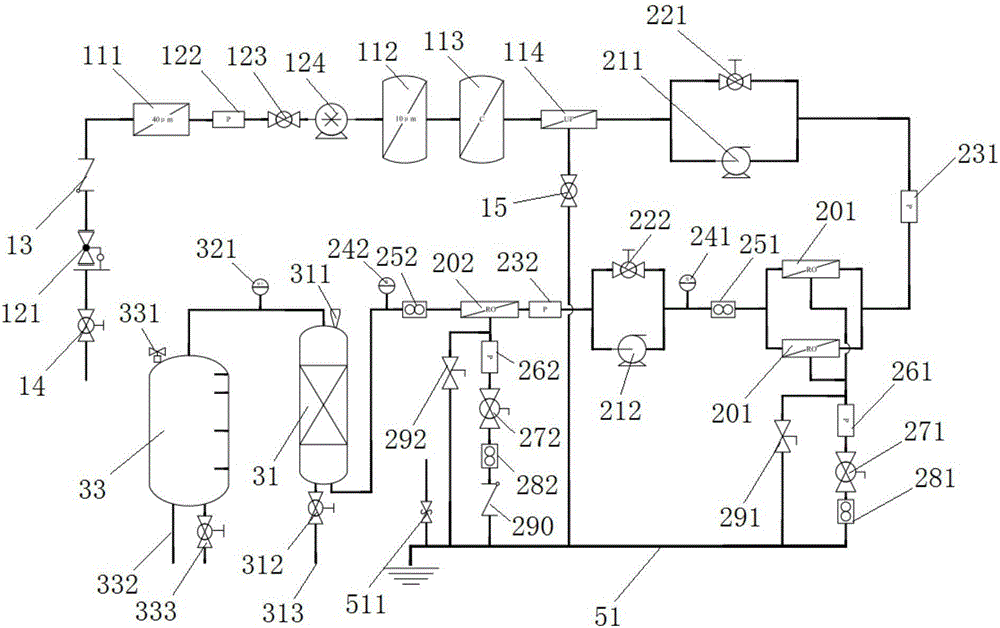

[0057] The reverse osmosis treatment device is used for reverse osmosis treatment of the primary filtered water. Wherein, the reverse osmosis treatment device includes a reverse osmosis treatment unit (such as figure 2 The shown ultrapure water ...

Embodiment 2

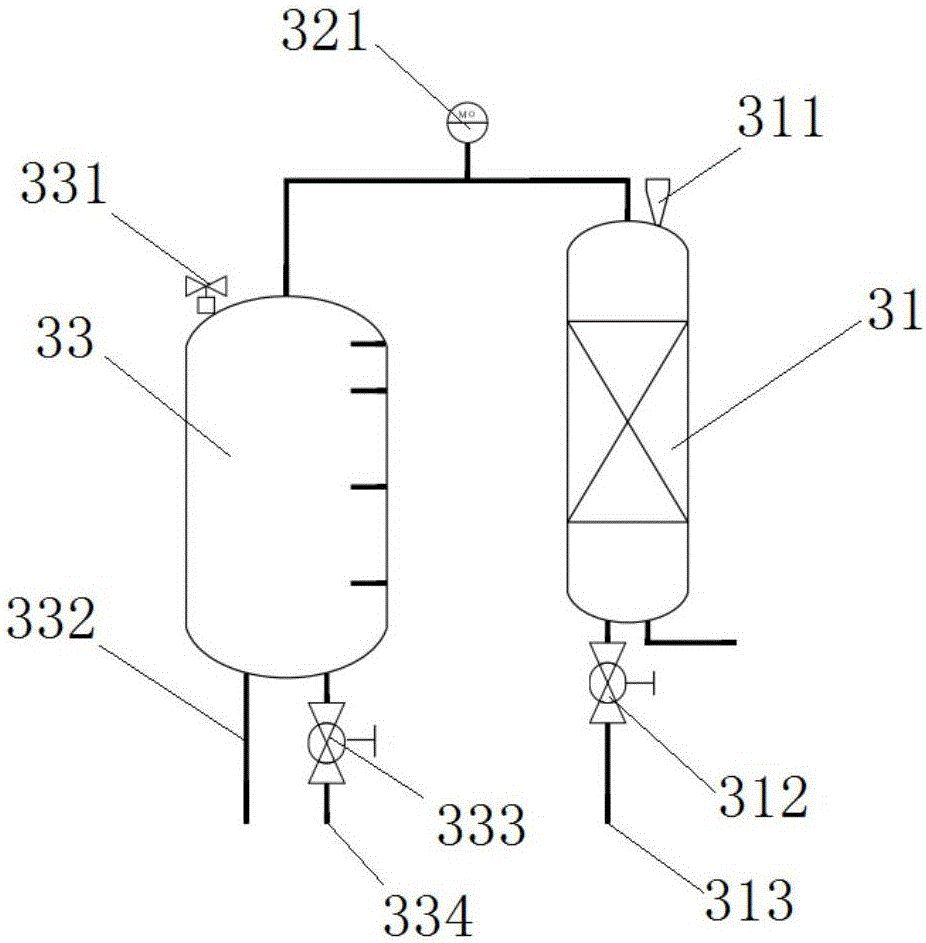

[0061] Preferably, this embodiment provides an ultrapure water preparation system, compared with the previous embodiment, such as figure 1 , figure 2 and image 3 As shown, the lower end of the polishing resin filter 31 in the polishing resin treatment device of this embodiment is connected to the water outlet pipeline of the reverse osmosis treatment device. The upper end of the polished resin filter is connected with an ultrapure water outlet pipeline. By setting in this way, the time for ion exchange between the reverse osmosis treated water and the polishing resin can be increased. Specifically, the water after the reverse osmosis treatment enters the polishing resin treatment filter 31 from the lower end of the polishing resin filter, and as the liquid level in the polishing resin filter 31 continues to rise, the water after the reverse osmosis treatment is fully mixed with the polishing resin Ion exchange is carried out, and the ultrapure water finally obtained enter...

Embodiment 3

[0069] Preferably, this embodiment provides an ultrapure water preparation system. Compared with the previous embodiment, the filter assembly of the pretreatment device in this embodiment includes a pre-filter, a filter element filter (a wire-wound filter element filter can be selected) One or more of filter or melt-blown PP cotton filter) and adsorption filter (granular activated carbon filter or carbon rod filter can be selected). Specifically, the filter assembly of the pretreatment device can increase or decrease the filter according to the local water quality.

[0070] Preferably, if figure 1 , figure 2 and Figure 4 As shown, the filter assembly in the pretreatment device in this embodiment can be configured as follows: a pre-filter 111 connected in sequence by pipelines, a wire-wound filter element filter 112 (the wire-wound filter element filter here can be melt-blown PP Cotton filter core filter replaces), granular activated carbon filter 113 (the granular activat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com