Etching-resistant jet ink and application thereof

An inkjet ink and anti-etching technology, applied in applications, anti-corrosion parts, inks, etc., can solve problems such as environmental pressure, long process, and various plate making, and achieve stable printing performance and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

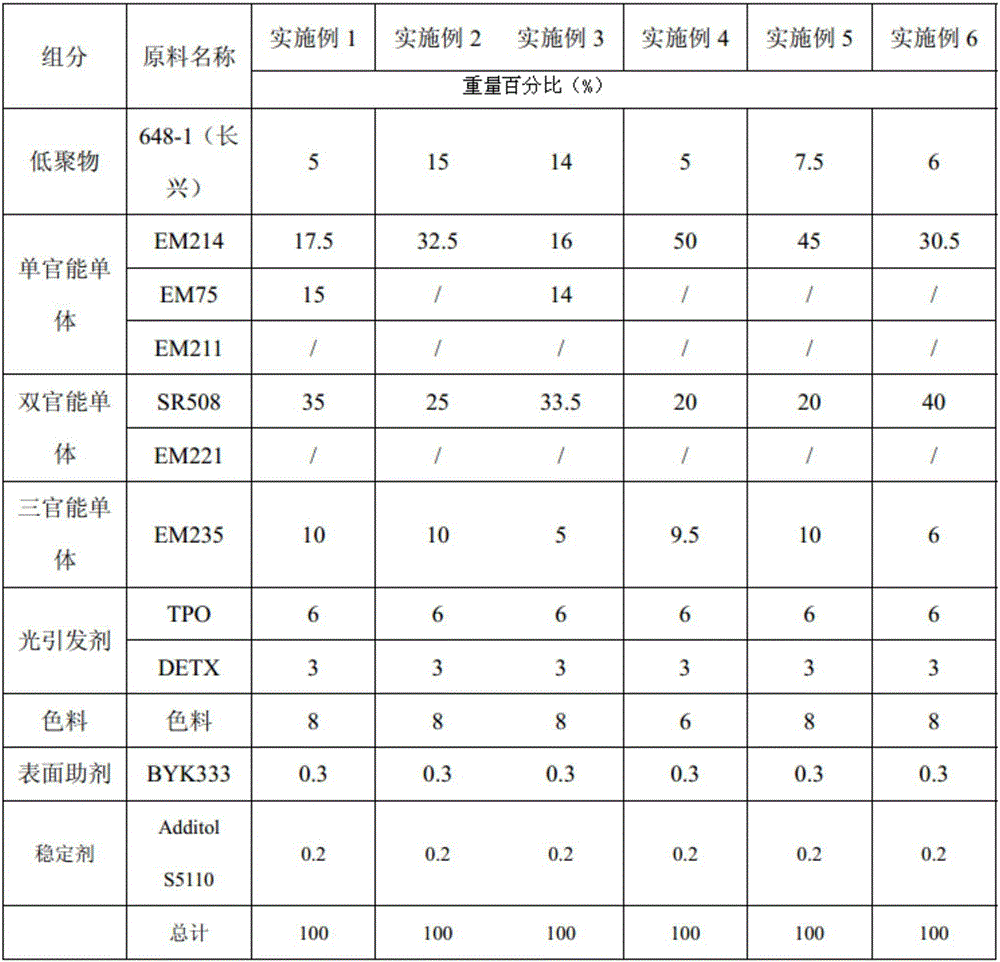

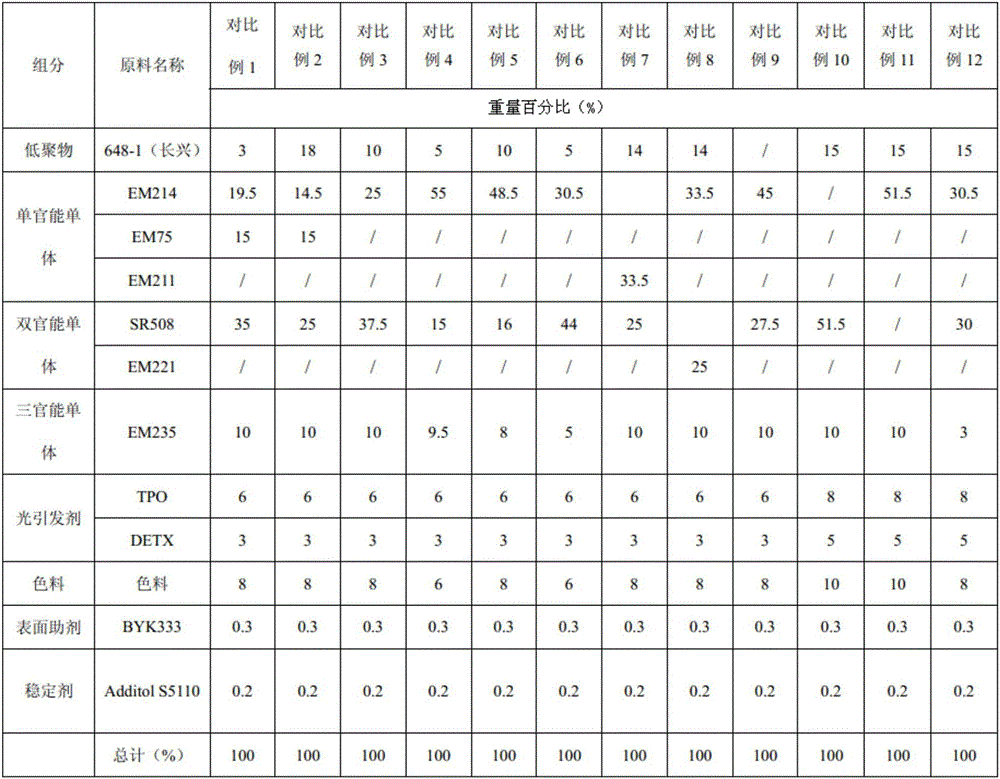

[0028] 1) take by weighing each component of embodiment 1-6 according to corresponding formula in following table 1;

[0029] 2) Mix monomers, oligomers, photoinitiators, and colorants, and stir until fully dissolved;

[0030] 3) Add surface additives and stabilizers, stir evenly, and filter with a filter membrane with a pore size of 1 μm under the condition of avoiding ultraviolet light indoors to complete ink preparation.

[0031] Table 1

[0032]

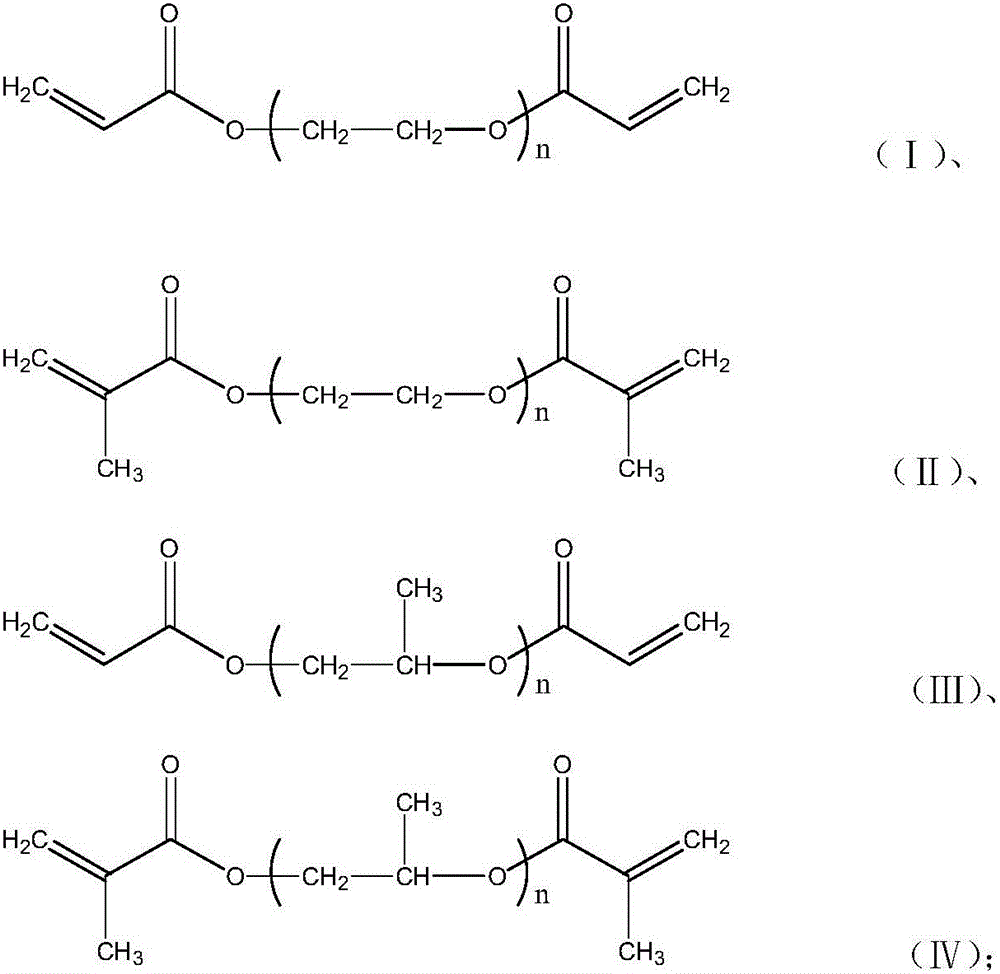

[0033] Oligomer 648-1 (Changxing) in Table 1 is carboxyl-containing acrylate; EM214 used is tetrahydrofurfuryl acrylate, EM75 is benzyl acrylate, EM211 is ethoxyethoxyethyl acrylate, EM221 is 1,6-hexanediol diacrylate, EM235 is pentaerythritol triacrylate, and SR508 is dipropylene glycol diacrylate. The colorant is specifically selected as SudanBlue670, and those skilled in the art can also select other existing colorants as required. The raw materials in Table 1 are all commercially available raw materials, among which, EM...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com