Composite inoculant for degrading petroleum, preparation method and applications thereof

A technology of compound bacterial agent and oil, applied in the field of oil pollution control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

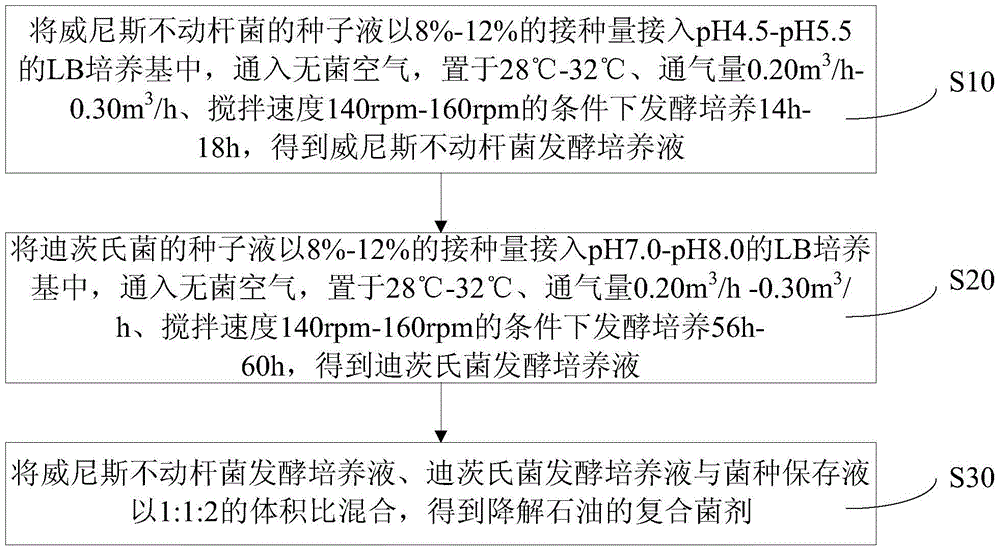

[0040] The preparation method of the above-mentioned composite bacteria agent for degrading petroleum of one embodiment comprises the following steps:

[0041] S10, insert the seed solution of Acinetobacter venezius into the LB culture medium of pH4.5-pH5.5 with the inoculum size of 8%-12%, feed sterile air, place at 28°C-32°C, ventilation volume 0.20m 3 / h-0.30m 3 Fermenting and culturing for 14h-18h under the conditions of stirring speed of 140rpm-160rpm per hour and stirring speed of 140rpm-160rpm, to obtain the Acinetobacter venicei fermentation culture liquid.

[0042] The preparation method of the seed solution of Acinetobacter venezius is as follows:

[0043] S110. Introduce the oil-contaminated soil collected from Dongying into sterilized LB culture solution, culture on a shaking table at 28°C-32°C for 22h-26h, and obtain Acinetobacter venezia after separation and purification.

[0044] In S110, the method of separation and purification is as follows:

[0045] Use ...

Embodiment 1

[0080] (1) Isolation of Acinetobacter venezia and Dietzella: Put the oil-contaminated soil collected from Dongying into the sterilized LB culture medium, cultivate it on a shaker at 30°C for 24 hours, and obtain Acinetobacter venezia and Dietzella sp.

[0081] (2) Test tube culture medium: Sterilized liquid LB medium was used to inoculate Acinetobacter veniceus into a test tube culture medium at pH 4.5, and after inoculation, it was placed on a shaker at 30° C. for 24 h of activation. Using sterilized liquid LB medium, Dietzella was inoculated into a test tube medium with pH 7.5, and after inoculation, it was placed on a shaker at 30°C for activation and culture for 24 hours.

[0082] (3) Expansion medium: use sterilized liquid LB medium, transfer the Acinetobacter venezius in the test tube culture medium to the Erlenmeyer flask medium at pH 4.5, place it in a shaker at 30°C, and culture it with shaking 24h, as seed solution. Using sterilized liquid LB medium, the Dietzella ...

Embodiment 2

[0088] (1) Isolation of Acinetobacter venezia and Dietzella: Introduce oil-contaminated soil into sterilized LB culture medium, culture on a shaking table at 28°C for 26 hours, and obtain Acinetobacter venezia after separation and purification and Dietzella.

[0089] (2) Test tube culture medium: Sterilized liquid LB medium was used to inoculate Acinetobacter veniceus into a test tube culture medium at pH 4.5, and after inoculation, it was placed in a shaker at 28°C for 26 hours of activation. Using sterilized liquid LB medium, Dietzella was inoculated into a test tube medium with pH 7.0, and placed in a shaker at 28°C for activating culture for 26 hours after inoculation.

[0090] (3) Expansion medium: use sterilized liquid LB medium, transfer the Acinetobacter venezius in the test tube culture medium to the Erlenmeyer flask medium at pH 4.5, place it in a shaker at 28°C, and shake it. 26h, as seed solution. Using sterilized liquid LB medium, transfer the Dietzella in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com