Electric power steering controller hardware function test board

A technology of electric power steering and hardware functions, which is applied in the direction of vehicle steering/bump performance, etc., can solve the problems of increasing time and equipment cost, idle test equipment and low utilization rate, and achieve the effect of reducing input cost and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

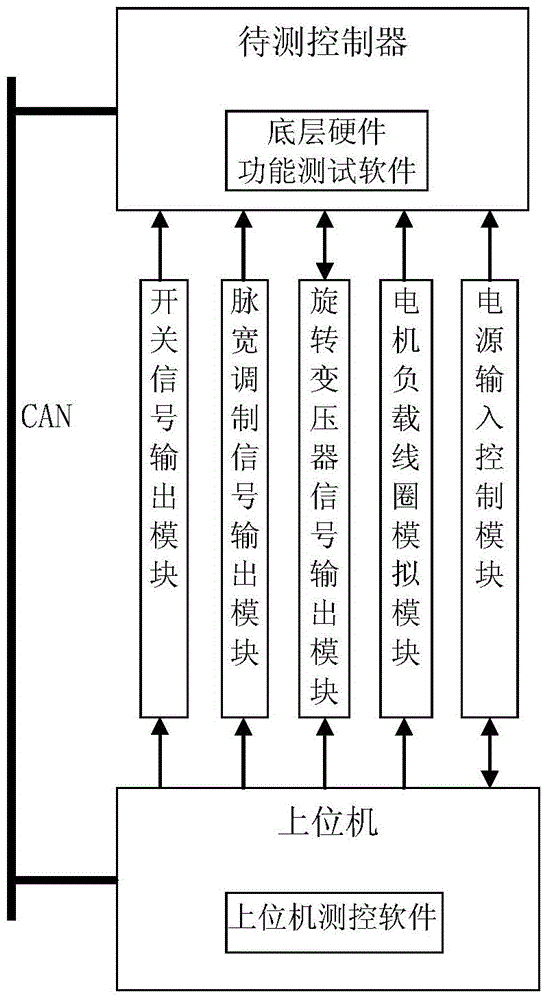

[0052]Electric power steering controller hardware function test bench, such as figure 1 As shown, including the host computer and the simulation signal generation module;

[0053] The controller to be tested is burned into the underlying hardware function test software;

[0054] The upper computer is provided with upper computer measurement and control software;

[0055] The host computer communicates with the controller to be tested, sends test instructions and simulation parameters to the controller to be tested, and receives test results fed back by the controller to be tested;

[0056] The host computer communicates with the simulation signal generation module, and sends simulation parameters to the simulation signal generation module;

[0057] The simulation signal generation module is used to generate a simulation signal according to the simulation parameters and instructions sent by the host computer and output it to the controller to be tested;

[0058] The underlyi...

Embodiment 2

[0062] Based on the first embodiment, the electric power steering controller hardware function test bench further includes a motor load coil simulation module;

[0063] The upper computer communicates with the motor load coil simulation module, and sends a load mode selection instruction to the motor load coil simulation module;

[0064] The motor load coil simulation module uses a three-phase coil to simulate a DC brushed motor load, and uses a two-phase coil to simulate a DC brushless motor load;

[0065] The motor load coil simulation module is used to connect to the controller under test in a three-phase coil mode or a two-phase coil mode according to the load mode selection instruction sent by the host computer.

[0066] In the hardware function test bench of the electric power steering controller of the second embodiment, before testing, the load type of the controller can be selected through the host computer, and the motor load coil simulation module switches the relay...

Embodiment 3

[0068] Based on the second embodiment, the electric power steering controller hardware function test bench further includes a power input control module;

[0069] The upper computer communicates with the power input control module, and sends the power setting parameters to the power input control module;

[0070] The power input control module is used to output the corresponding voltage or current to the controller under test according to the power setting parameters sent by the upper computer.

[0071] Preferably, the power input control module communicates with the upper computer through a serial port communication protocol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com