A headspace sampler control system and control method

A headspace sampler and control system technology, applied in the control/regulation system, sequence/logic controller program control, electrical program control, etc., can solve the problems of difficult expansion, poor anti-interference ability, high failure rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0095] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

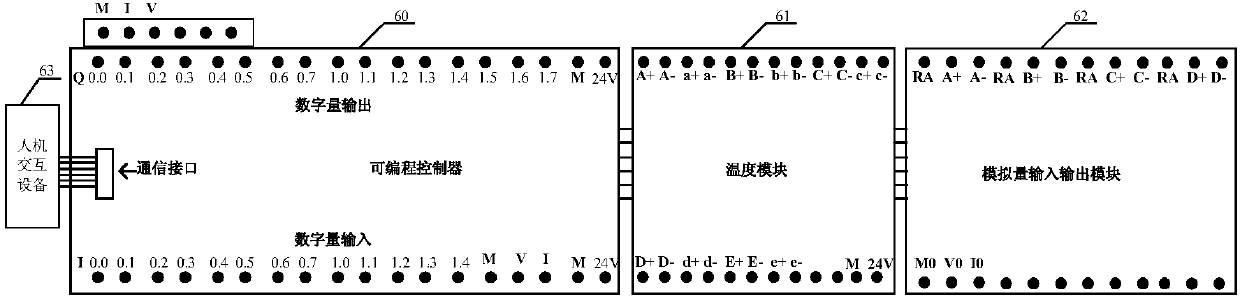

[0096] The headspace sampler control system of this embodiment, such as figure 1 As shown, the system includes programmable controller 60 (model S7-200 CPU224XP CN), temperature module 61 (model EM231 AI8xRTD), analog input and output module 62 (model EM235 CN) and human-computer interaction device 63 (model SK- 043AE), in which, the programmable controller 60 adopts a PLC model of S7-200 CPU224XP CN, the temperature module 61 adopts a model of EM231 AI8xRTD, the analog input and output module adopts a model of EM235 CN, and the human-computer interaction device 63 The display and control touch screen man-machine interface model SK-043AE is used.

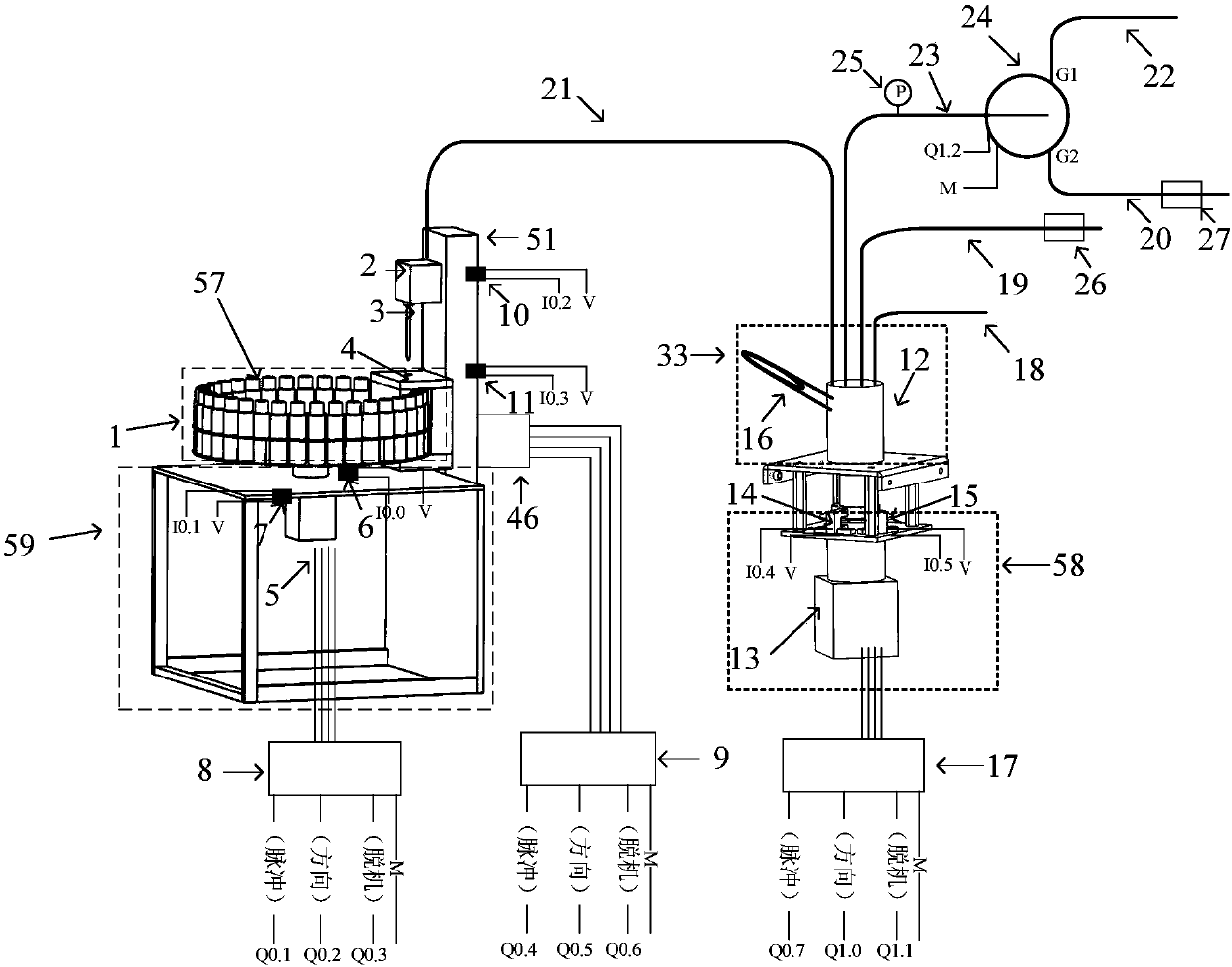

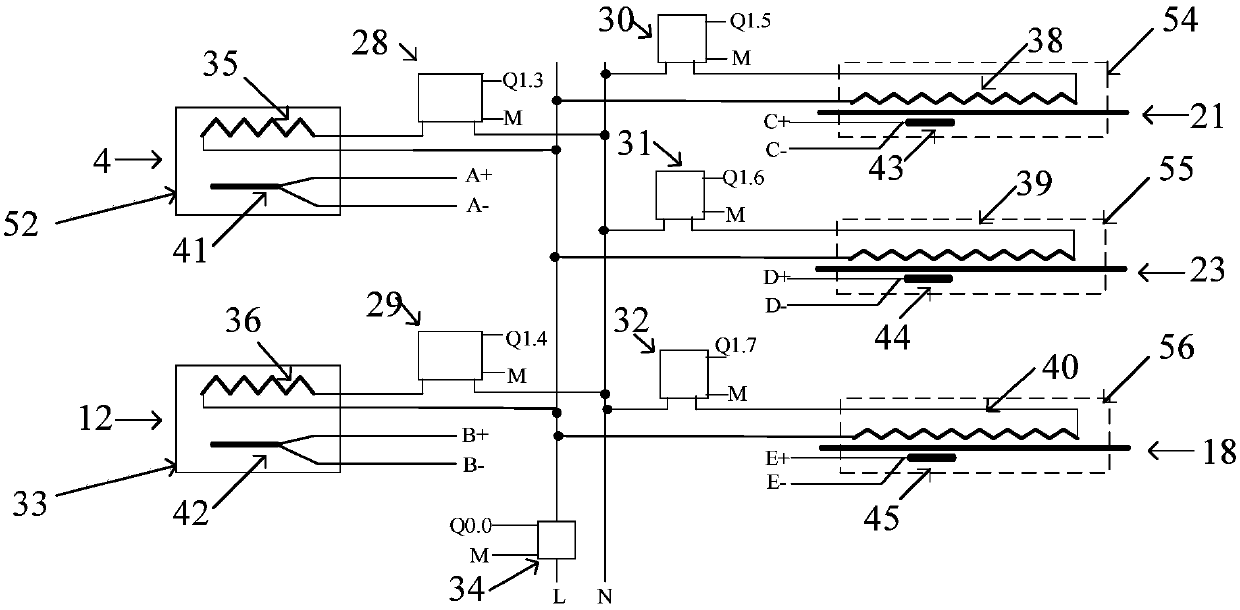

[0097] Such as figure 2 As shown, the first output terminal Q0.0 of the programmable controller 60 is connected to the input terminal of the 220V power relay 34 of the headspace sample...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com