Wine material agitation tank with split agitating paddle

A stirring paddle, split-type technology, applied in the field of wine mixing tanks, can solve the problems of difficult blade processing, troublesome cleaning of blades, unstable stirring, etc., and achieve the effect of low cost, convenient processing and manufacturing, and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

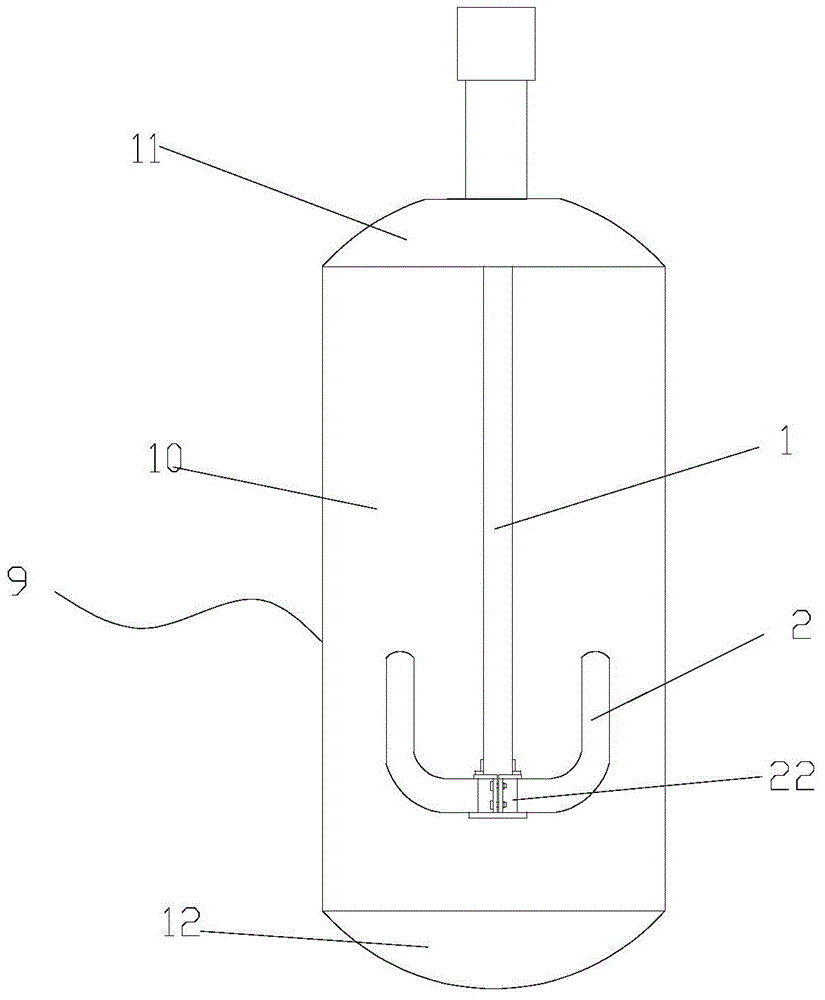

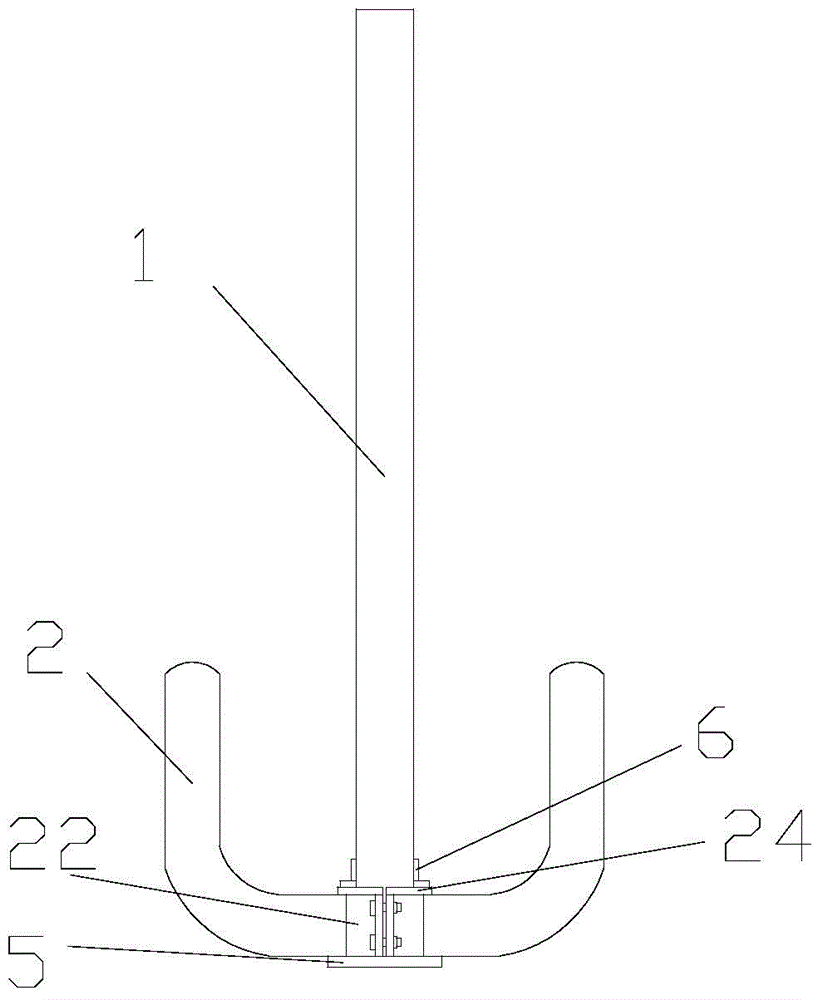

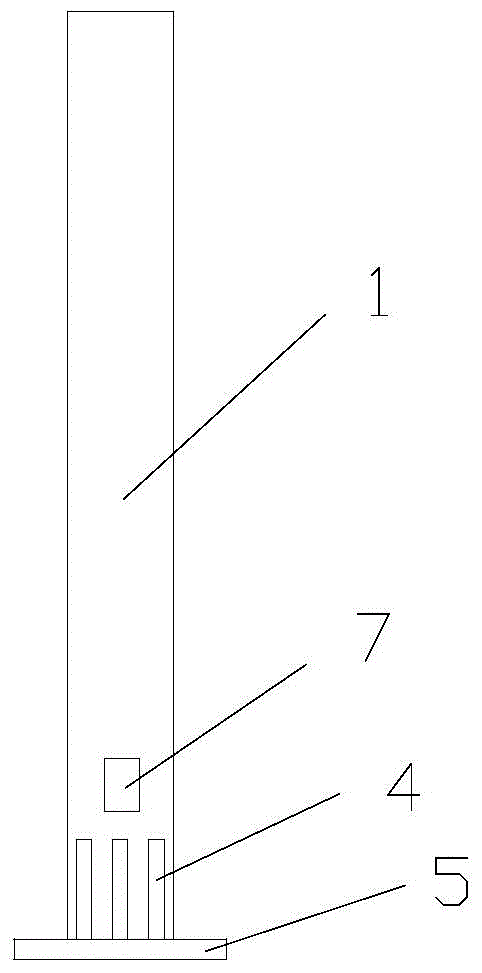

[0017] As shown in the figure: the wine material stirring tank of the concrete split stirring paddle of the present embodiment includes a reaction tank 9 and a stirring paddle, and the reaction tank 9 includes a tank body 10, an upper sealing head 11 and a lower sealing head 12. The upper sealing head 11 is connected with the tank body 10 by welding, and the upper sealing head 11 is provided with a feeding port. The stirring paddle includes a stirring shaft 1 and a paddle 2. The paddles 2 all include a paddle body 21 and a connecting portion 22 integrally formed with the paddle body 21 and connected with the stirring shaft 1 in a key fit. The connecting portions 22 of the two paddles 2 are connected to each other, and the lower end of the stirring shaft 1 A connecting section 3 is provided, the outer side of the connecting section 3 is provided with a connecting key 4 along the axial direction, the connecting portion 22 is semicircular, and the inner side of the connecting port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com