Quantum dot nanomaterial synthetic apparatus

A technology of nanomaterials and synthesis devices, applied in the field of quantum dots, can solve problems such as complexity, affecting the quality of quantum dots, and the inability to expand quantum dot production on a large scale, so as to simplify operations and improve quantum yields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

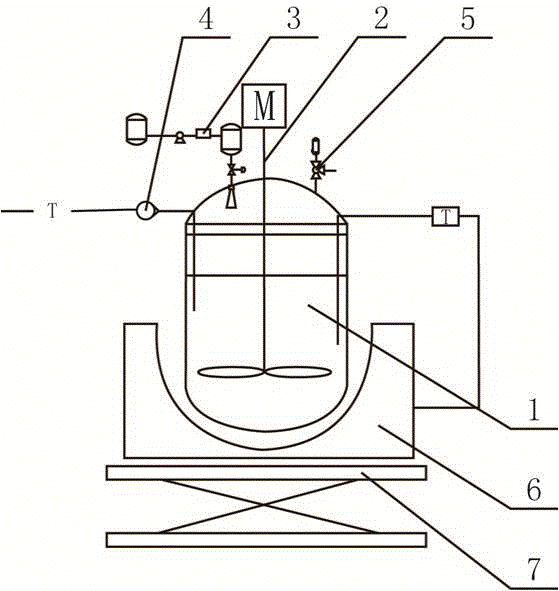

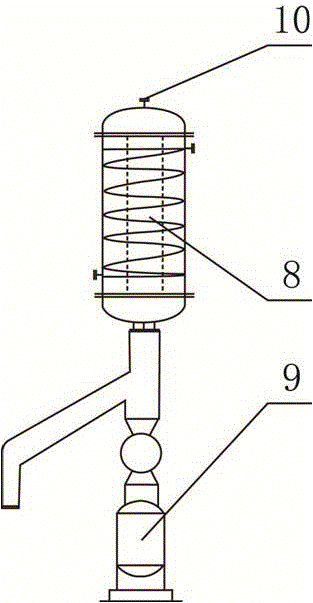

[0015] Such as figure 1 figure 2 As shown, the reaction device includes a reaction part 1, a stirring part 2, a feed part 3, a gas protection part 4, a tail liquid collection part 5, a heating part 6 and a lifting part 7, the reaction part 1 is located above the heating part 6, and the reaction part 1 A stirring part 2, a feeding part 3, a gas protection part 4 and a tail liquid collecting part 5 are arranged on the top, and the heating part 6 is located on the lifting part 7. The reaction part 1 is equipped with a first reactant, solvent and reflux, the feed part 3 is equipped with a second reactant, and the gas protection part 4 is filled with an inert gas. The tail liquid collecting part 5 includes a condensation reflux device 8 , a collection bottle 9 and a gas outlet 10 ; the condensation reflux device 8 is one of gas condensation and liquid condensation. The gas inlet of the gas protection part 4 is placed below the liquid surface of the reaction part 1, the gas outle...

Embodiment 2

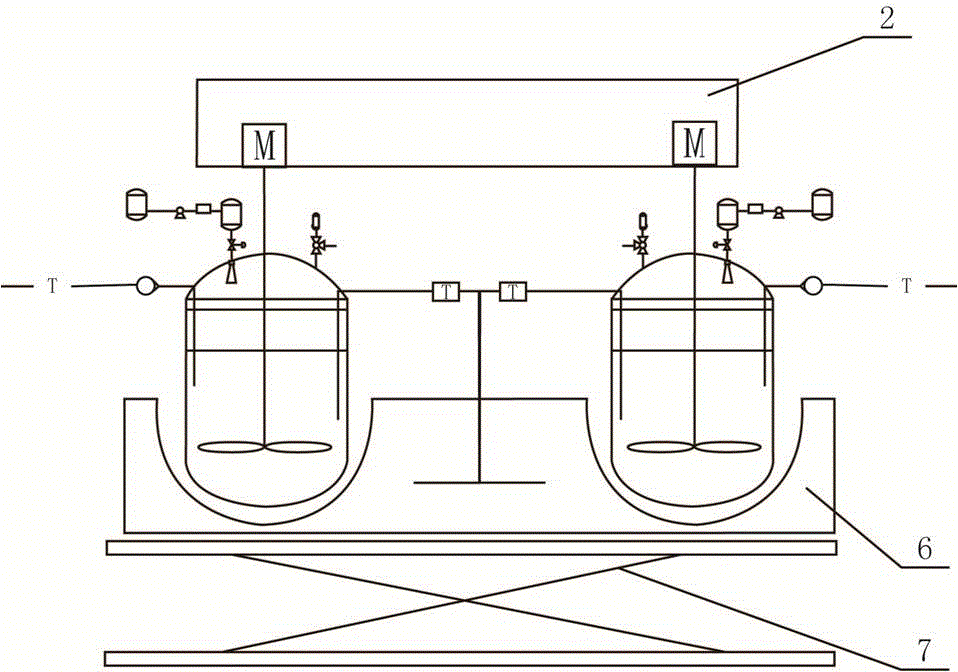

[0020] Such as image 3 As shown, two reaction devices are connected in parallel to form a two-row row. Wherein the stirring part 2 is fixed in the same box, the heating part 6 is combined together, and the lifting part 7 is combined together, and can be lifted simultaneously.

Embodiment 3

[0022] Such as Figure 4 As shown, four reaction devices are connected in parallel to form a quadruple row. Wherein the stirring part 2 is fixed in the same box, the heating part 6 is combined together, and the lifting part 7 is combined together, and can be lifted simultaneously.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com