Energy-saving insulation box for tubular wet electrostatic precipitator

A wet electrostatic precipitator and insulating box technology, applied in the field of dust collectors and energy-saving insulating boxes, can solve the problems of inability to guarantee quality, waste of working time, and high power consumption, and achieve the effects of beautiful appearance, energy saving and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

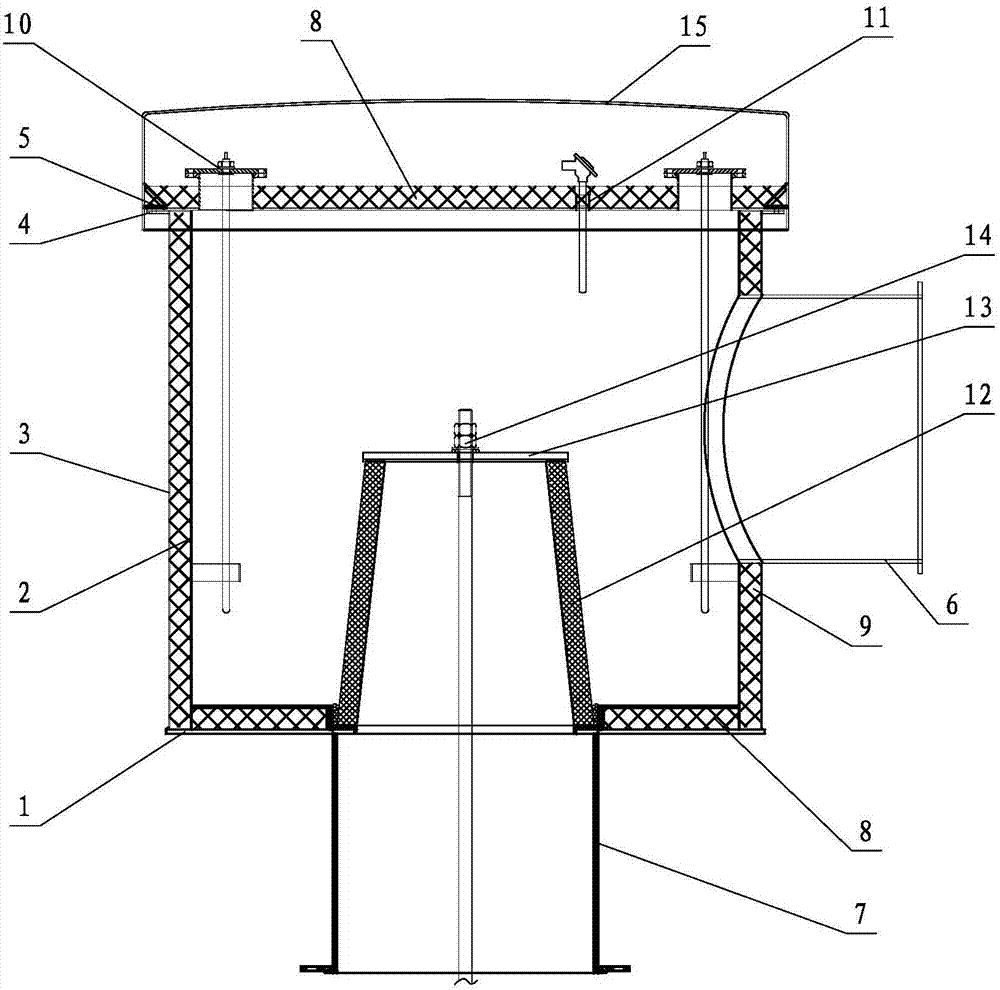

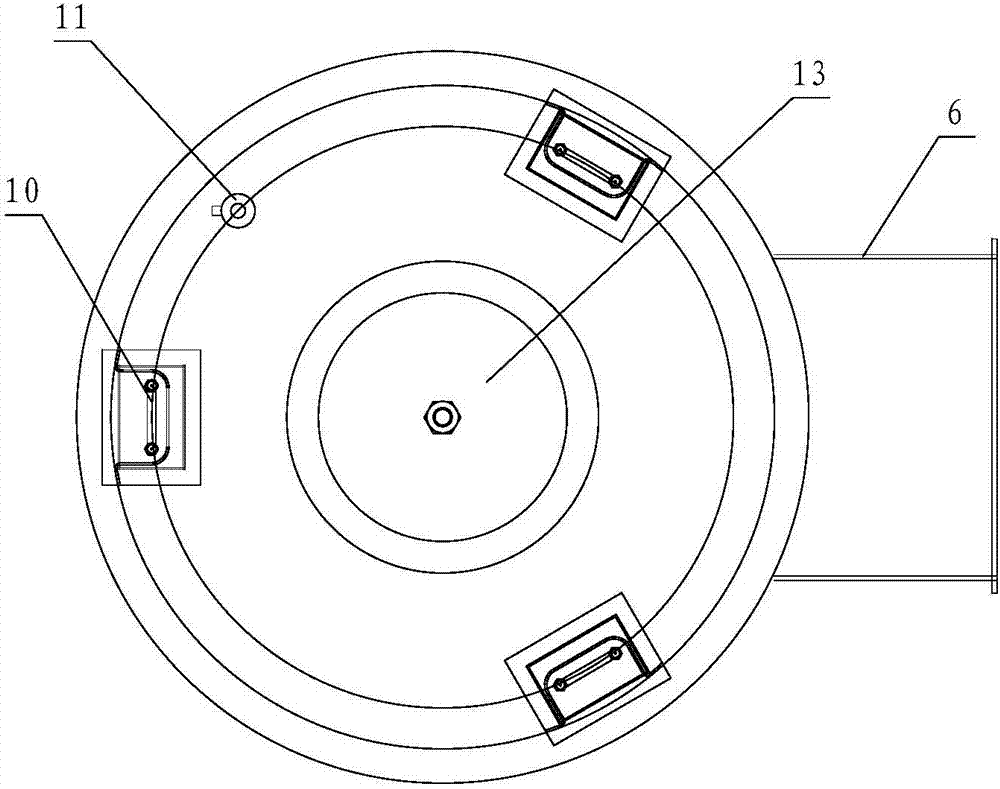

[0018] Such as figure 1 and figure 2 As shown, the energy-saving insulation box used for the tubular wet electrostatic precipitator includes a double-layer cylinder and a control cabinet. The double-layer cylinder includes a bottom plate 1, and an inner cylinder 2 and an outer cylinder 3 are fixed on the bottom plate 1. There is an insulation gap between the outer cylinder and the outer cylinder 3, the first insulation filler 9 is filled in the insulation gap, the second insulation material 8 is laid on the bottom surface of the inner cavity of the inner cylinder 2, and the tops of the inner cylinder 2 and the outer cylinder 3 are sealed and covered with a cover 5. The second thermal insulation material 8 is laid on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com