Main shaft double-position positioning device for rhombic metal mesh knitting machine

The technology of a net weaving machine and a positioning device is applied in the directions of online nets, household appliances, other household appliances, etc., which can solve the problems of affecting the edge lock, difficult to adjust the power supply voltage of the electromagnetic brake, difficult to adjust and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] In order to enable those skilled in the art to better understand the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

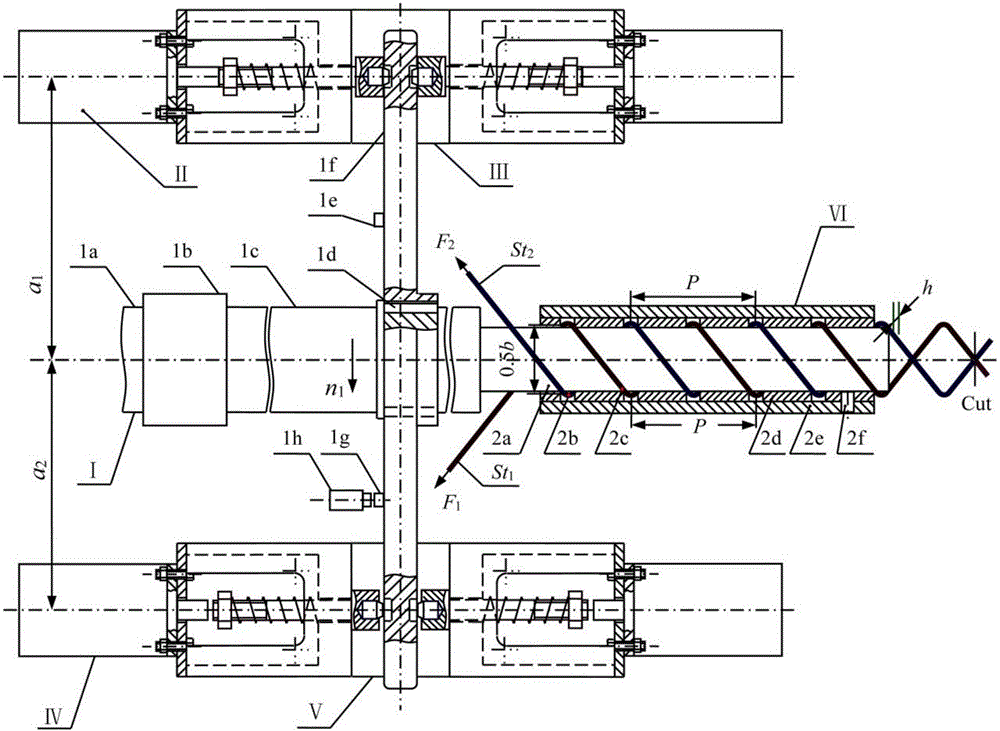

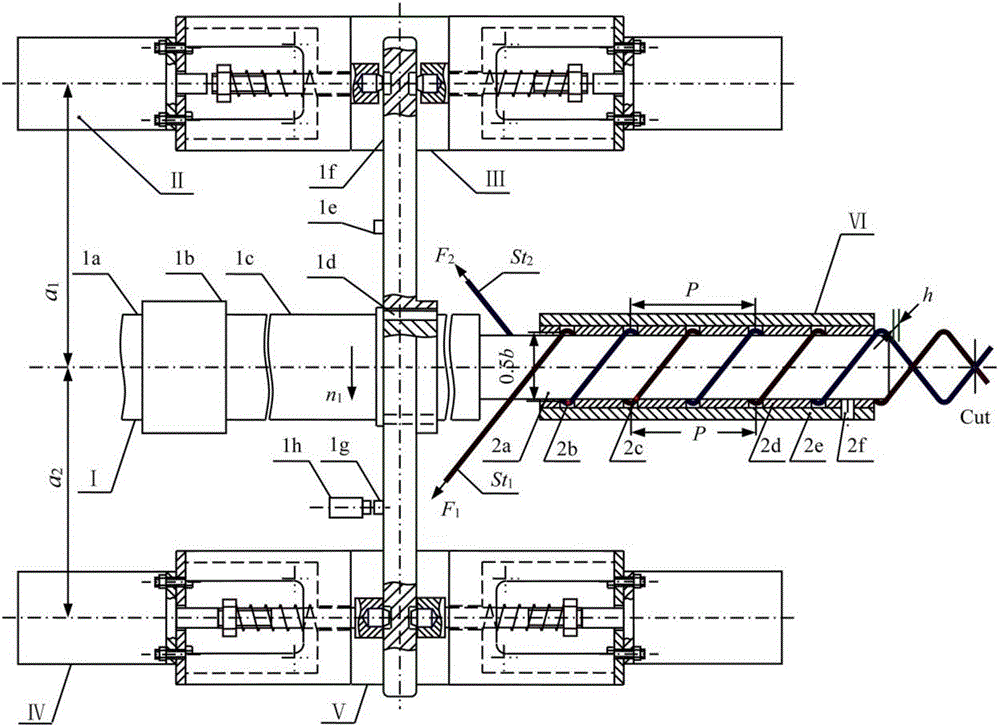

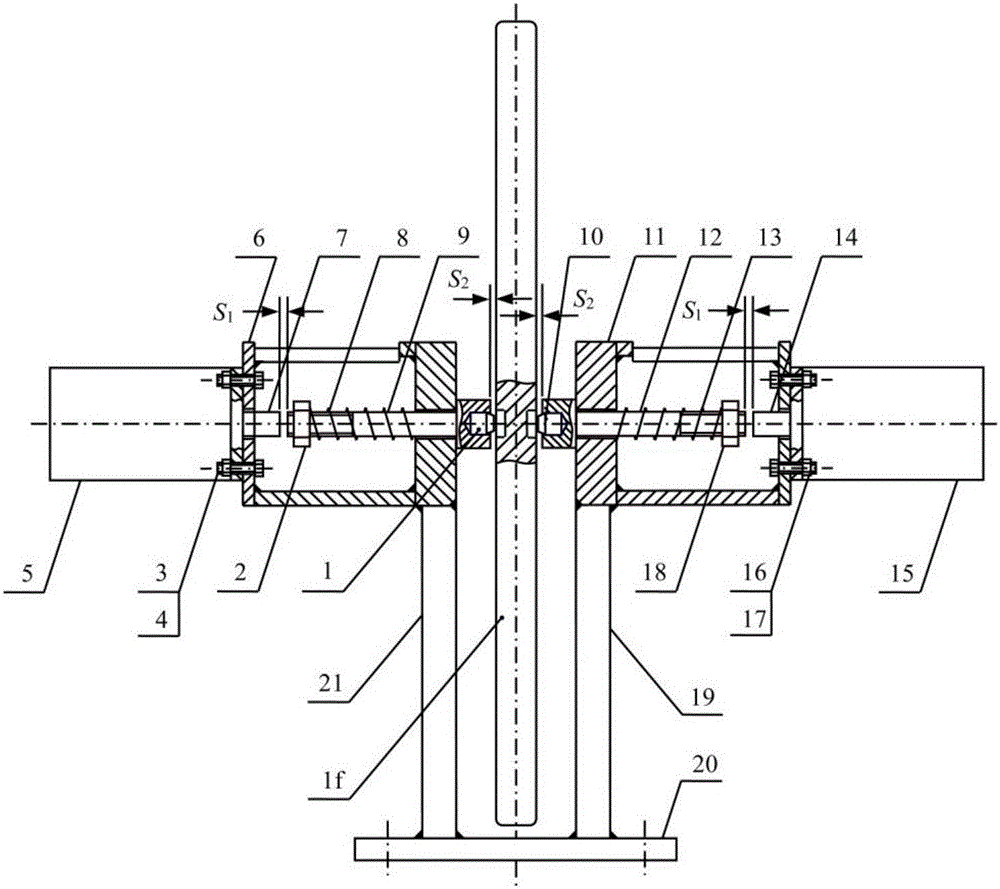

[0059] As shown in the picture figure 1 , figure 2 The double-position positioning device for the main shaft of a rhombic metal mesh knitting machine is shown, which includes a main shaft sensor system I, a main shaft upper positioning electromagnet push rod system II, a main shaft upper positioning electromagnet push rod system bracket III; a main shaft lower positioning electromagnet push rod system Rod system IV, spindle lower positioning electromagnet push rod system support V, forming structure VI of two inter-winding flat spiral steel wires, spindle input end 1a rotates continuously, when electromagnetic clutch 1b is energized, spindle output end 1c is driven, the spindle The output terminal 1c is connected with the key 1d to drive t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com