Laser welding device and method based on laser cleaning pretreatment

A laser welding and laser cleaning technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as unfavorable environmental protection, complicated chemical removal procedures, etc., to improve welding efficiency, realize automatic cleaning and welding, Significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

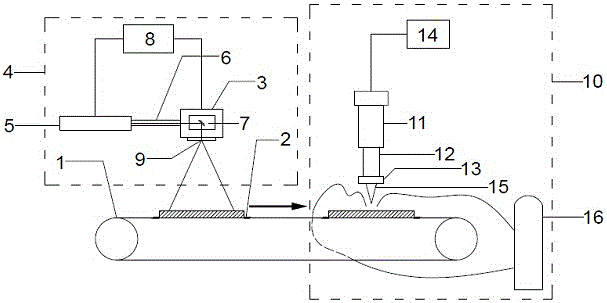

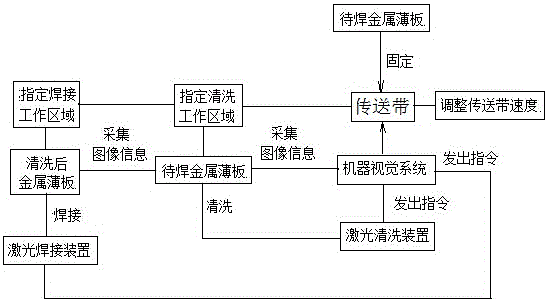

[0022] like figure 1 As shown, a laser welding device based on laser cleaning pretreatment includes a conveyor belt 1, a clamping and adsorption device 2, a machine vision system 3, a laser cleaning device 4, a pulsed laser 5, a beam transmission system A6, a beam focusing system A7, Control system A8, scanning head 9, laser welding device 10, continuous laser 11, beam transmission system B12, beam focusing system B13, control system B14, welding head 15, shielding gas bottle 16 and shielding gas pipeline.

[0023] The front part of the conveyor belt 1 is provided with a laser cleaning work area, and the rear part is provided with a laser welding work area. A laser cleaning device 4 is installed in the laser cleaning work area, and a laser welding device 10 is installed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com