A dust removal system for a dust-free stone carving grinding system

A dust removal system and stone carving technology, applied in grinding/polishing equipment, grinding/polishing safety devices, electromechanical devices, etc., can solve problems such as unfavorable motor rapid heat dissipation, reduce the number of sewage replacements, and avoid system performance degradation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

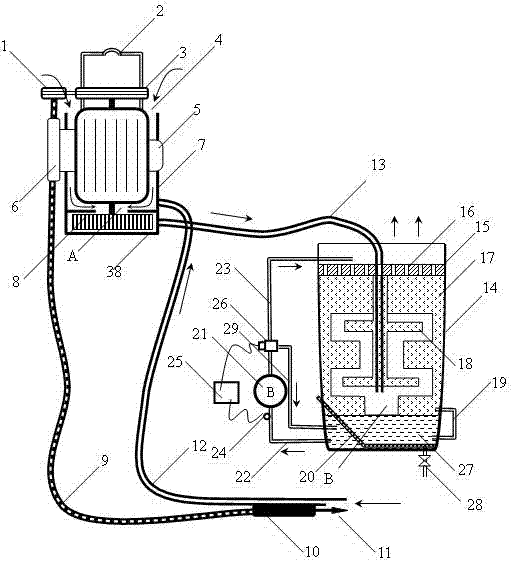

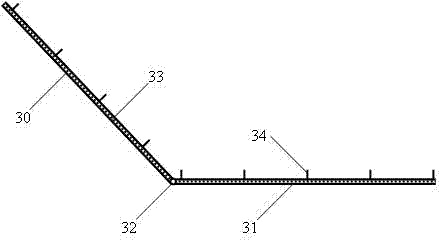

[0050] Example 1: if figure 1 , figure 2 , image 3 A dust-free stone carving grinding system, including dust suction grinding equipment and a dust removal system, is characterized in that: the dust suction grinding equipment uses the motor 5 of the grinding tool as the power of the suction and dust suction equipment, and the suction and suction The dust equipment sucks the air outside the motor 5 to cool down the motor 5, and at the same time sucks the dust generated by the grinding machine, and the dirty gas containing dust is discharged into the dust removal system. There is a space between the outer sponge 17 and the inner sponge 18 in the container 14 of the dust removal system. A cavity is formed, the lower space of the container 14 is filled with water, the coarse particles of dirty gas are directly sprayed into the water, and the circulation pump 21 circulates water supply to the sponge, and the gas containing fine particles is absorbed by the sponge and cleaned by w...

example 2

[0051] Example 2: According to Example 1, a more preferred dust-absorbing grinding equipment of a dust-free stone carving grinding system includes a grinding tool and an air suction and dust suction system, and is characterized in that:

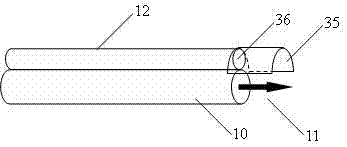

[0052] The grinding tool includes a driven wheel 1, a hook 2, a driving wheel 3, a motor 5, a flexible shaft mounting frame 6, a flexible shaft 9, a handle 10, and a grinding tool 11. The main shaft of the motor 5 is connected with the driving wheel 3, and the motor 5 A hook 2 is installed on the top, a flexible shaft mounting frame 6 is arranged on the side of the motor 5, a flexible shaft 9 is installed in the flexible shaft mounting frame 6, the upper end of the flexible shaft 9 has a driven wheel 1, and the other end of the flexible shaft 9 is connected with a handle 10 , the front end of the handle 10 is equipped with a grinding tool 11;

[0053] The air suction and dust suction system includes a shroud 7 installed on the outer side and ...

example 3

[0060] Example 3: According to example 1-2, the dust removal system of a more preferred dust-free stone carving grinding system includes a container 14 and a water circulation system for filtering, and is characterized in that:

[0061] An outer sponge 17 and an inner sponge 18 are installed in the container 14;

[0062] The outer sponge 17 has a cavity, and a cavity is formed between the outer sponge 17 and the inner sponge 18;

[0063] The bottom of the outer sponge 17 has a connecting hole discharge port B;

[0064] The container 14 also includes a deflector 15 on the top of the outer sponge 17, and holes 16 are distributed on the deflector 15;

[0065] The container 14 also includes an opening on the side;

[0066] The bottom of the container 14 is equipped with a cleaning filter plate 20, and one end of the cleaning filter plate 20 stretches out from the opening on the side of the container 14 to the outside of the container 14;

[0067] The cavity 27 between the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com