An automatic production line for inorganic decorative panels

A technology of automatic production line and inorganic decorative board, applied in the direction of ceramic molding machine, molding conveyor, ceramic molding workshop, etc., can solve the problem of discontinuous processing technology and achieve the effect of ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0026] The following examples are only examples for clearly illustrating the present invention, rather than limiting the implementation of the present invention. For those of ordinary skill in the art, on the basis of the following descriptions, other different forms of changes or changes can also be made, and these obvious changes or changes that belong to the spirit of the present invention are still within the protection scope of the present invention middle.

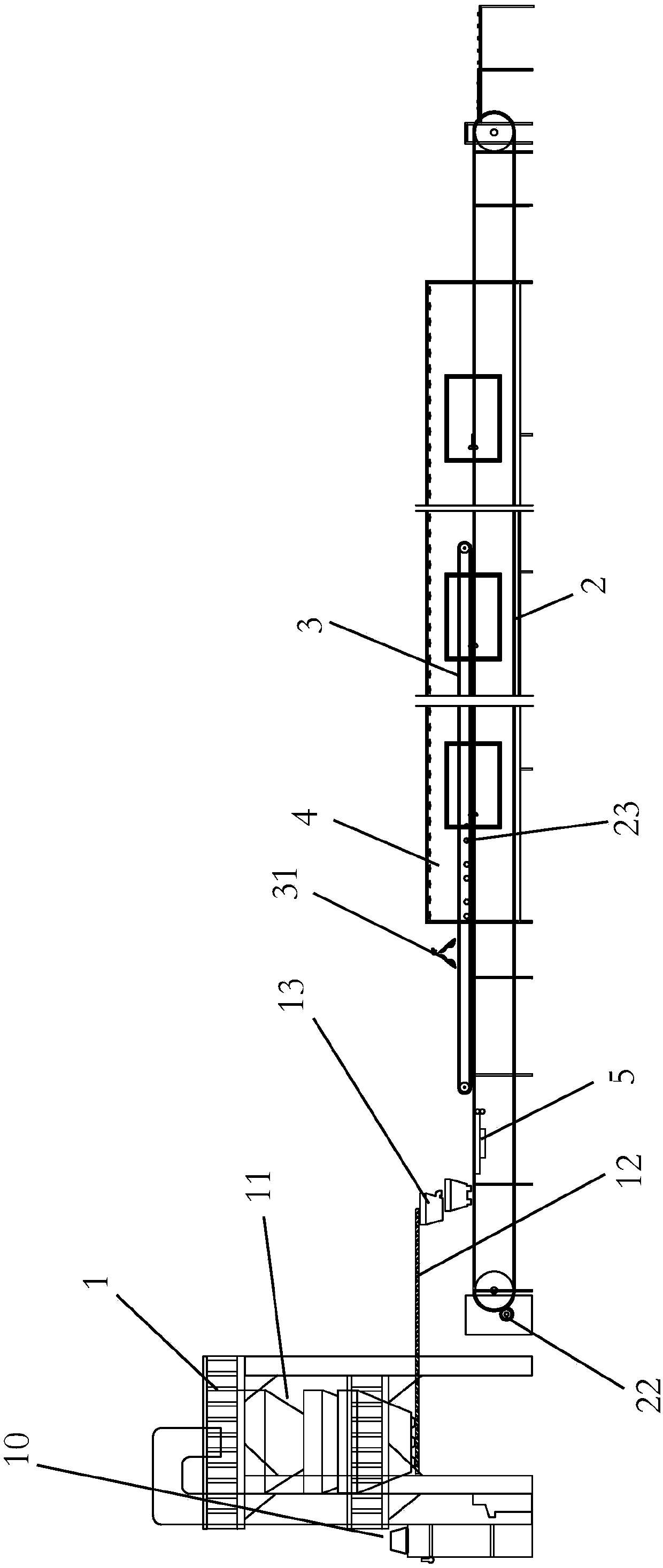

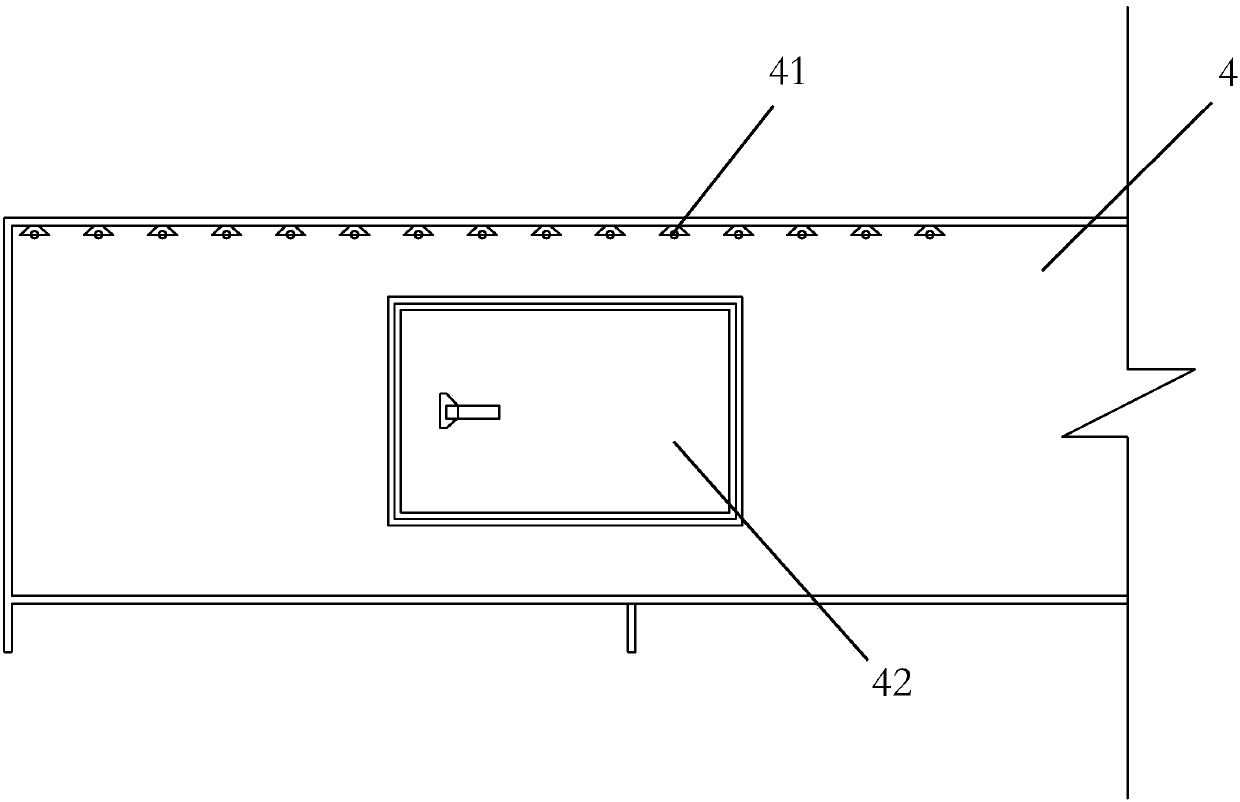

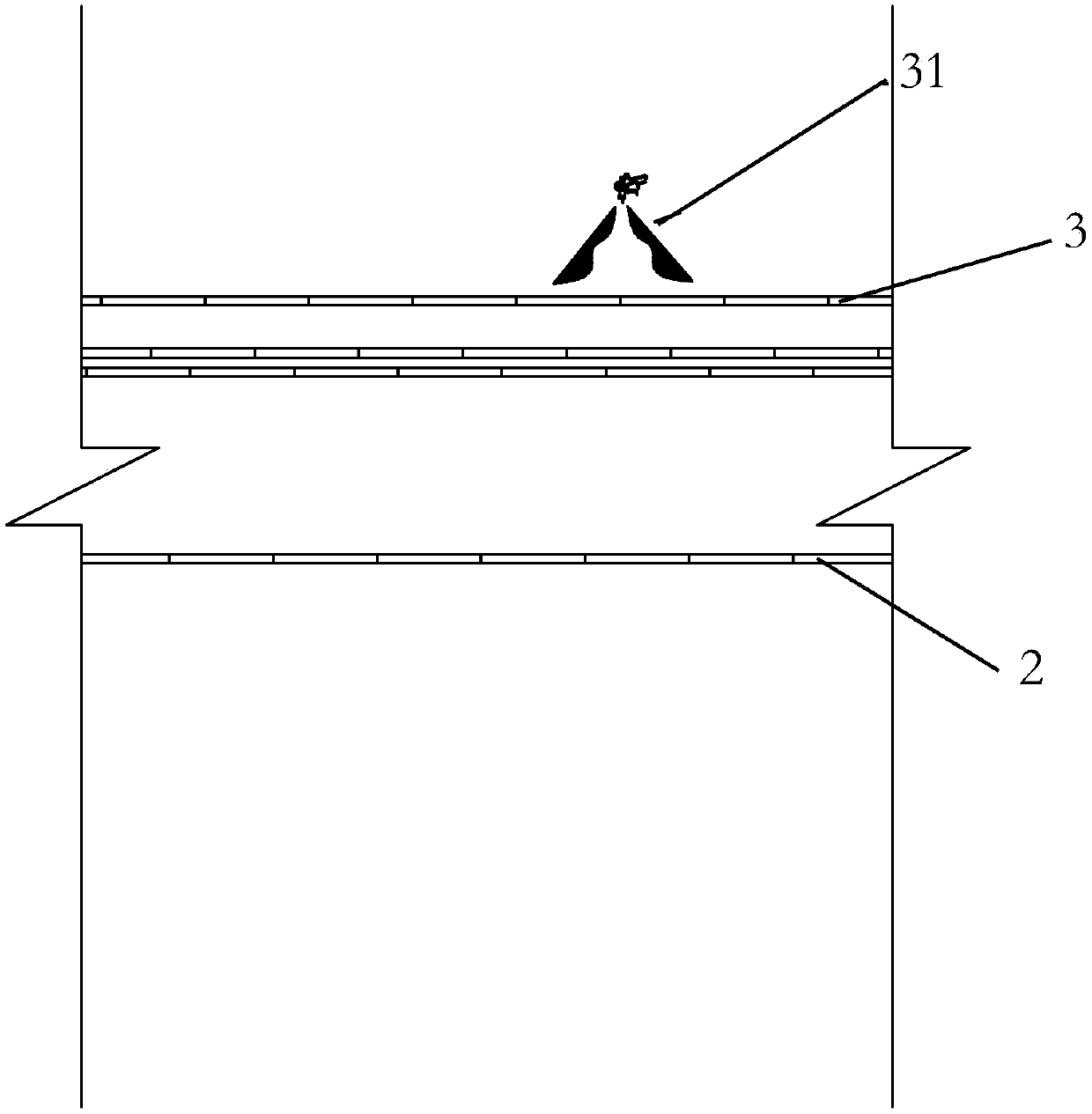

[0027] An automatic production line for inorganic decorative panels, comprising a blank material feeding system, a bottom mold belt circular conveyor line 2, a cover mold demoulding conveyor line 3, the bottom mold belt circular conveyor line 2, and the cover mold demoulding conveyor line 3 are both The two ends of the endless conveyor belt conveyor line are driven by rollers. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com