Silk-screen printing and sintering net belt connector

A connector, mesh belt technology, applied in the direction of semiconductor devices, sustainable manufacturing/processing, electrical components, etc., can solve the problems of fragmentation, height inconsistency, easy to drop chips, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

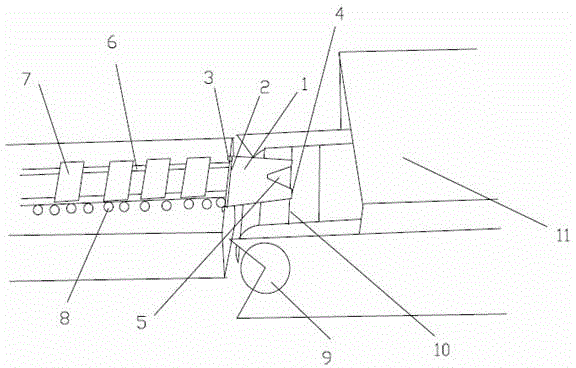

[0015] In order to further describe the present invention, the specific implementation manner of the screen-printed sintered mesh belt connector will be further explained below in conjunction with the accompanying drawings.

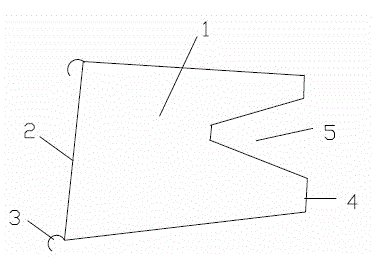

[0016] Such as figure 1 As shown, a silk screen sintered mesh belt connector is made of a trapezoidal flat plate 1, the width of the left side 2 is slightly larger than the width of the screen printing conveyor belt, the right side 4 is a small strip, and there is an inverted trapezoidal hollow body 5 in the middle. And left side 2 edge both sides have hook 3.

[0017] Preferably, the length of the trapezoidal flat plate 1 is greater than the distance between the screen printing conveyor belt 6 and the mesh belt of the sintering furnace.

[0018] Preferably, the surface of the trapezoidal planar plate 1 is smooth.

[0019] Preferably, the trapezoidal flat plate 1 is made of high temperature resistant and wear resistant materials.

[0020] Preferably, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com