Skid-mounted thermal energy self-circulation sludge drying system device

A sludge drying and system device technology, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of low drying temperature, accident-prone, short life, etc., achieve high drying temperature, improve drying Efficiency, long life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

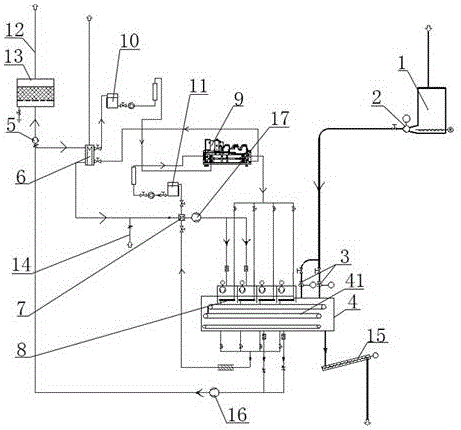

[0016] Referring to the accompanying drawings, the skid-mounted thermal energy self-circulation sludge drying system device includes a sludge system and a hot air and hot water system. The sludge system includes a sludge tank 1, a sludge pump 2, a sludge noodle machine 3, and a sludge Drying machine 4, the lower end of the sludge tank 1 is connected to the sludge noodle machine 3 through a pipeline, and a sludge pump 2 is installed on the pipeline, and the outlet of the sludge noodle machine 3 is installed on the drying chain plate 41 of the sludge drying machine 4 Above; the hot air and hot water system includes exhaust fan 5, H105 heat exchanger system 6, H106 heat exchange system 7, H101-104 internal heat exchange system 8, and the upper end of the sludge dryer 4 is equipped with H101-104 internal heat exchange system 8. The upper end of the H101-104 internal heat exchange system 8 is connected to the H106 heat exchange system 7 through the air duct pipeline, and the other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com