Lead-cadmium-free compound glass powder for printing ink for windshield of automobile and preparation method thereof

A technology for windshield and composite glass, applied in coating and other directions, can solve the problem of unretrieved patent documents of lead- and cadmium-free composite glass powder, and achieve the effects of good gloss, good anti-stick performance and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

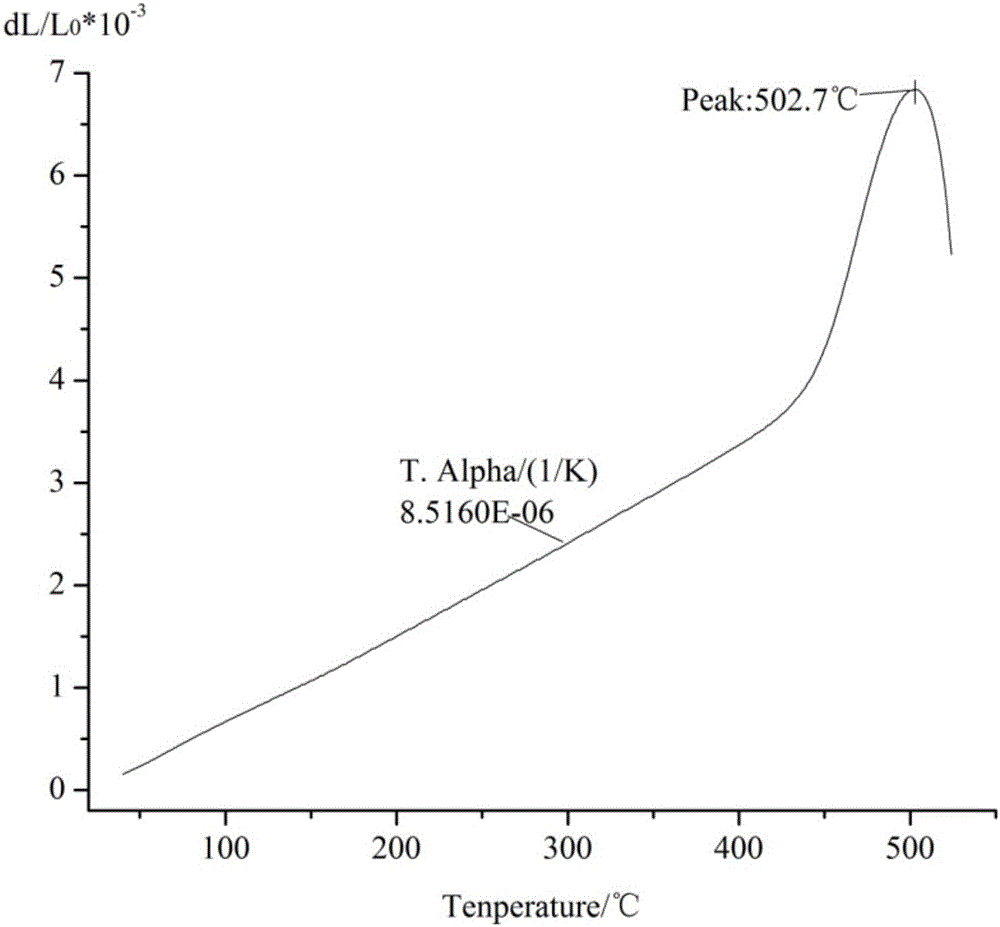

Embodiment 1

[0039] A kind of lead-free cadmium composite glass powder for automobile windshield printing ink, its component comprises the ③ number Bi in table 1 2 o 3 -B 2 o 3 -SiO 2 System glass powder and No. 1 Nb in Table 2 2 o 5 -ZnO-B 2 o 3 -SiO 2 System glass powder, the two system glass powders are fully mixed according to the mass ratio of 2:1.

[0040] Concrete preparation process is as follows:

[0041] (1) Ingredients: According to the mass percentage of No. ③ component in Table 1, take and prepare Bi 2 o 3 -B 2 o 3 -SiO 2 Raw material Bi of system glass frit 2 o 3 、H 3 BO 3 , ZnO, SiO 2 、Na 2 CO 3 and K 2 CO 3 Standby; according to the mass percentage of No. 1 component in Table 2, take and prepare Nb 2 o 5 -ZnO-B 2 o 3 -SiO 2 Raw material Nb of system glass frit 2 o 5 , ZnO, SiO 2 、H 3 BO 3 、MoO 3 、TiO 2 、Na 2 CO3 、K 2 CO 3 , Li 2 CO 3 , ZrO 2 and Al 2 o 3 spare.

[0042] (2) Melting of glass: two kinds of glass frit raw materials th...

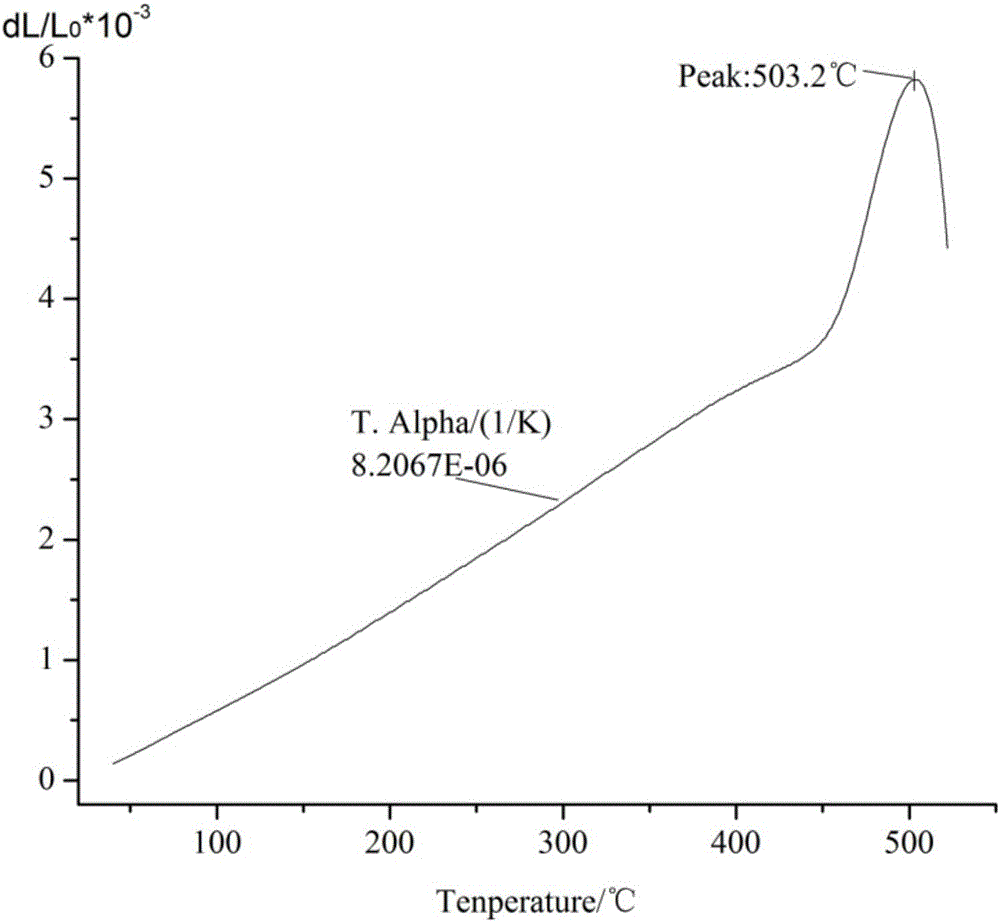

Embodiment 2

[0047] A kind of lead-free cadmium composite glass powder for automobile windshield printing ink, its component comprises the ④ number Bi in table 1 2 o 3 -B 2 o 3 -SiO 2 System glass powder and No. 3 Nb in Table 2 2 o 5 -ZnO-B 2 o 3 -SiO 2 System glass powder, the two system glass powders are fully mixed according to the mass ratio of 3:1.

[0048] Concrete preparation process is as follows:

[0049] (1) Ingredients: according to the mass percentage of No. ④ component in Table 1, take and prepare Bi 2 o 3 -B 2 o 3 -SiO 2 Raw material Bi of system glass frit 2 o 3 、H 3 BO 3 , ZnO, SiO 2 、Na 2 CO 3 and K 2 CO 3 Standby; According to the mass percentage of No. 3 component in Table 2, take and prepare Nb 2 o 5 -ZnO-B 2 o 3 -SiO 2 Raw material Nb of system glass frit 2 o 5 , ZnO, SiO 2 、H 3 BO 3 、MoO 3 、TiO 2 、Na 2 CO 3 、K 2 CO 3 , Li 2 CO 3 , ZrO 2 and Al 2 o 3 spare.

[0050] (2) Melting of glass: two kinds of glass frit raw materials ...

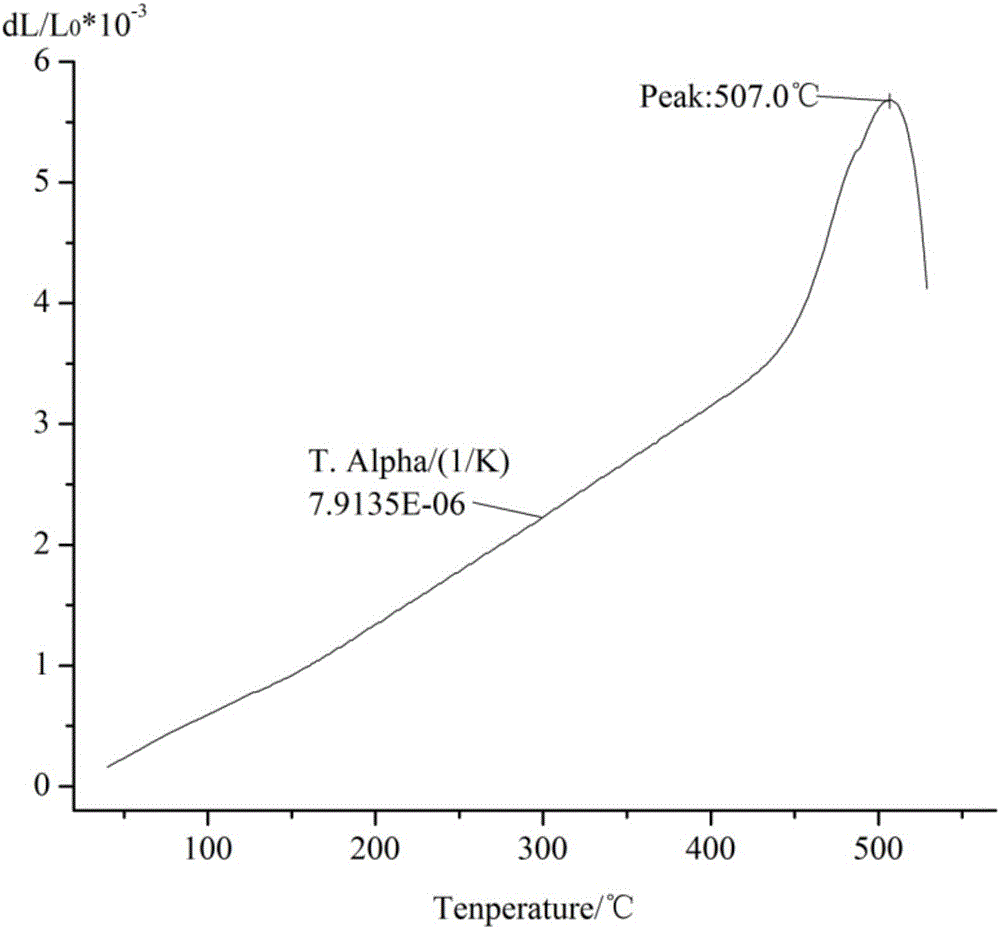

Embodiment 3

[0056] A kind of lead-free cadmium composite glass powder for automobile windshield printing ink, its component comprises ② No. Bi in table 1 2 o 3 -B 2 o 3 -SiO 2 System glass powder and No. 4 Nb in Table 2 2 o 5 -ZnO-B 2 o 3 -SiO 2 System glass powder, the two system glass powders are fully mixed according to the mass ratio of 4:1.

[0057] Concrete preparation process is as follows:

[0058] (1) Ingredients: according to the mass percentage of No. ② component in Table 1, take and prepare Bi 2 o3 -B 2 o 3 -SiO 2 Raw material Bi of system glass frit 2 o 3 、H 3 BO 3 , ZnO, SiO 2 、Na 2 CO 3 and K 2 CO 3 Standby; According to the mass percentage of No. 4 component in Table 2, take and prepare Nb 2 o 5 -ZnO-B 2 o 3 -SiO 2 Raw material Nb of system glass frit 2 o 5 , ZnO, SiO 2 、H 3 BO 3 、MoO 3 、TiO 2 、Na 2 CO 3 、K 2 CO 3 , Li 2 CO 3 , ZrO 2 and Al 2 o 3 spare.

[0059] (2) Melting of glass: two kinds of glass frit raw materials that take...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Softening temperature | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com