Novel aerobic continuous closed type drum reactor

A reactor and closed technology, applied in the field of new aerobic continuous closed drum reactor, can solve the problems of affecting the normal use of equipment, easy blockage of blast holes, slow reaction speed, etc., achieving compact structure, not easy to agglomerate, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

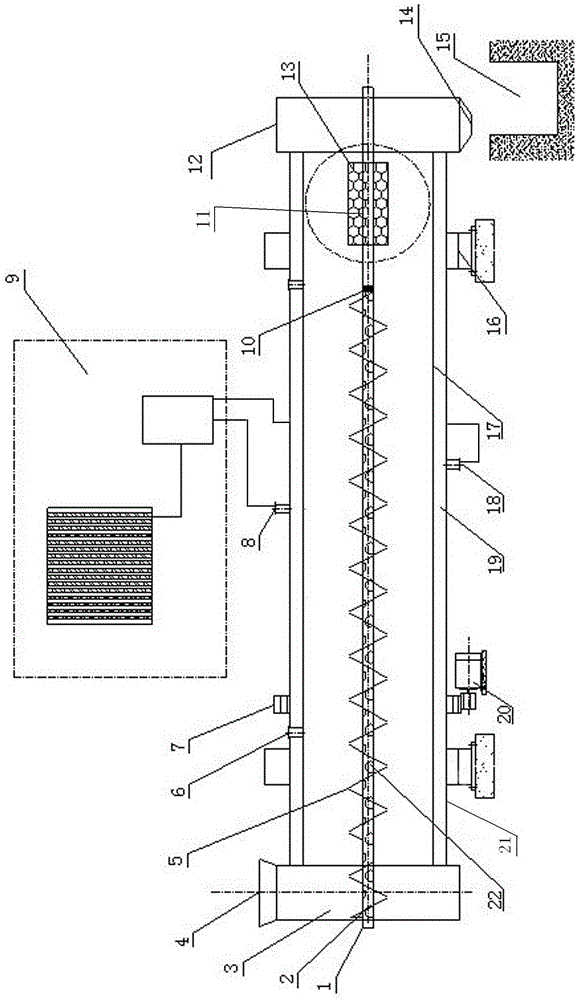

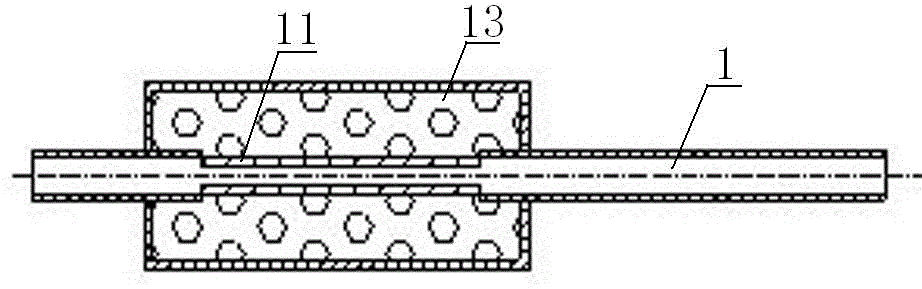

[0024] A new type of aerobic continuous closed drum reactor, which is composed of a reactor part and a water bath heating part. The reactor part is composed of a feed hopper (3), a discharge hopper (12), a reactor (17) and an aeration Composed of screw (1); the reactor is a hollow cylinder, and the feed hopper and discharge hopper are respectively arranged at both ends of the reactor; the aeration screw is a hollow screw, and the aeration screw passes through the feed hopper , the reactor and the discharge hopper are set, and the screw rod is evenly provided with aeration holes (22); the end of the aeration screw near the discharge hopper is provided with a gas stop valve (10) and an air outlet filter screen (13); the water bath The heating device is composed of a solar water heating device (9) and a water bath shell (21) sleeved outside the reactor. There is a water bath jacket (19) between the water bath shell and the reactor. The water bath jacket A temperature detection de...

Embodiment 2

[0034] A new type of aerobic continuous closed drum reactor, which is composed of a reactor part and a water bath heating part. The reactor part is composed of a feed hopper (3), a discharge hopper (12), a reactor (17) and an aeration Composed of screw (1); the reactor is a hollow cylinder, and the feed hopper and discharge hopper are respectively arranged at both ends of the reactor; the aeration screw is a hollow screw, and the aeration screw passes through the feed hopper , the reactor and the discharge hopper are set, and the screw rod is evenly provided with aeration holes (22); the end of the aeration screw near the discharge hopper is provided with a gas stop valve (10) and an air outlet filter screen (13); the water bath The heating device is composed of a solar water heating device (9) and a water bath shell (21) sleeved outside the reactor. There is a water bath jacket (19) between the water bath shell and the reactor. The water bath jacket A temperature detection de...

Embodiment 3

[0044] A new type of aerobic continuous closed drum reactor, which is composed of a reactor part and a water bath heating part. The reactor part is composed of a feed hopper (3), a discharge hopper (12), a reactor (17) and an aeration Composed of screw (1); the reactor is a hollow cylinder, and the feed hopper and discharge hopper are respectively arranged at both ends of the reactor; the aeration screw is a hollow screw, and the aeration screw passes through the feed hopper , the reactor and the discharge hopper are set, and the screw rod is evenly provided with aeration holes (22); the end of the aeration screw near the discharge hopper is provided with a gas stop valve (10) and an air outlet filter screen (13); the water bath The heating device is composed of a solar water heating device (9) and a water bath shell (21) sleeved outside the reactor. There is a water bath jacket (19) between the water bath shell and the reactor. The water bath jacket A temperature detection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com