Olaparib and urea eutectic and preparation method thereof

A technology of urea and eutectic crystal form, which is applied in the field of cocrystal and preparation of olaparib and urea, can solve the problem of low solubility of free base crystal form, simplify the preparation and post-treatment process, and improve bioavailability , Improve the effect of drug absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Preparation of Olaparib and Urea Cocrystal Form A:

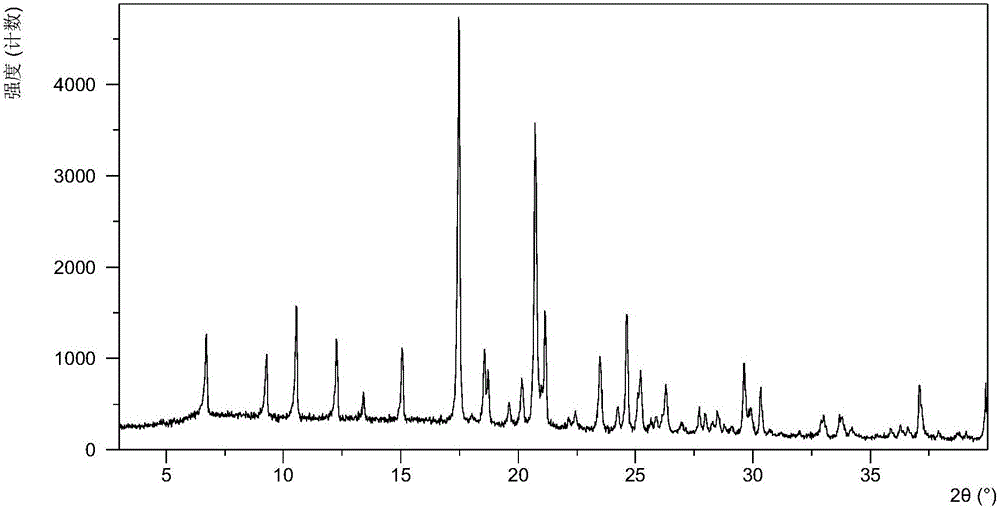

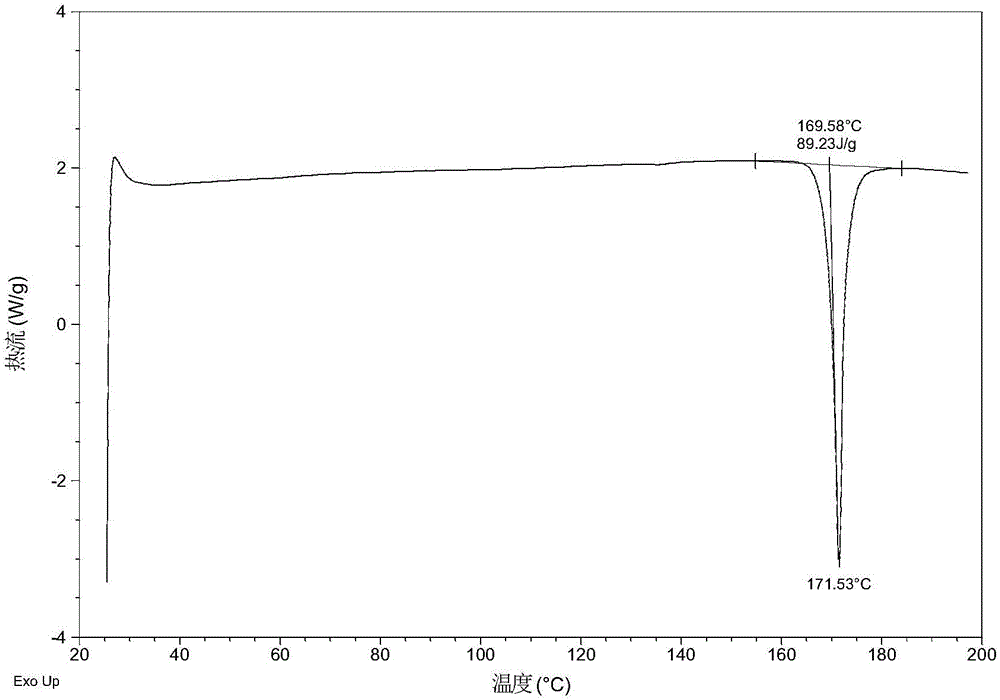

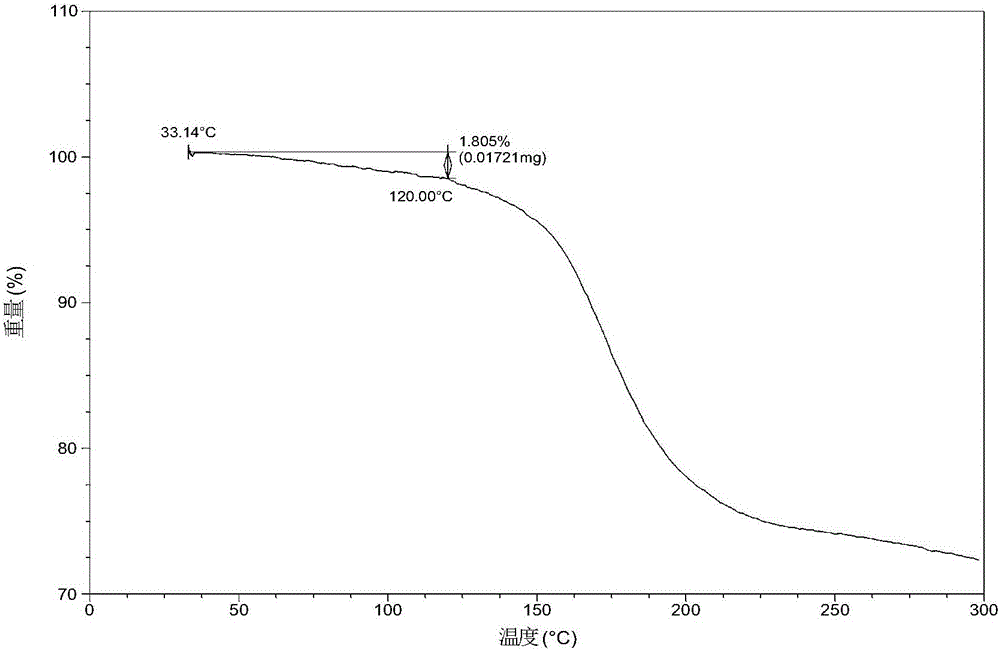

[0056] Dissolve 10.0 mg of olaparib free base (amorphous) in 0.6 mL of ethanol, add 11.8 mg of urea, heat to 60 °C at a heating rate of 1.0 °C / min, stir at 60 °C for 600 min, and then heat at 0.37 °C / min The temperature was lowered to 5° C. at a cooling rate of min, and the above heating and cooling process was repeated three times. After the reaction was completed, it was filtered, and the obtained solid was washed with ethanol, dried, and collected. After testing, the solid obtained in this embodiment is eutectic crystal form A, and its XRPD pattern is as follows figure 1 , and its X-ray powder diffraction data are shown in Table 1. Its DSC diagram is as follows figure 2 , and its TGA figure is shown in image 3 ,That 1 HNMR picture as shown Figure 6 .

[0057] The eutectic product of olaparib and urea prepared by the above method, its 1HNMR identification data are as follows:

[0058] 1 HNMR(400MHz,DMSO)δ...

Embodiment 2

[0063] Preparation method of co-crystal of olaparib and urea: 101.9 mg of olaparib free base was dissolved in 3.0 mL of ethanol, 98.7 mg of urea was added, heated to 60 °C at a heating rate of 1.0 °C / min, and then Stir at 60°C for 600min, then cool down to 5°C at a cooling rate of 0.37°C / min, repeat the above heating and cooling process three times, filter after the reaction, and wash the obtained solid with ethanol and dry.

[0064] After testing, the solid obtained in this example is crystal form A, and its X-ray powder diffraction data are shown in Table 2.

[0065] Table 2

[0066]

[0067]

Embodiment 3

[0069] Preparation of co-crystals of olaparib and urea:

[0070] Dissolve 10.0 mg of olaparib free base (amorphous) in 0.6 mL of acetone, add 10.8 mg of urea, heat to 60 °C at a heating rate of 1.0 °C / min, stir at 60 °C for 600 min, and cool down (cooling rate 0.37 °C / min) to 5 °C, repeat the above heating and cooling process three times, filter after the reaction, and wash the obtained solid with ethanol, dry, cool to room temperature, and collect the solid.

[0071] After testing, the solid obtained in this example is consistent with the crystal form obtained in Example 1, which is the eutectic crystal form A, and its X-ray powder diffraction data are shown in Table 3.

[0072] table 3

[0073]

[0074]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com