Polystyrene reflection material and preparation method thereof

A polystyrene and reflective material technology, applied in the field of optical materials, can solve the problems of complex process, deterioration, deformation of reflective film, etc., and achieve the effect of simple production process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

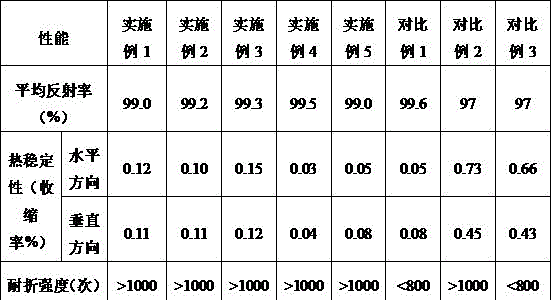

Examples

Embodiment 1

[0022] Polystyrene reflective material, according to the ratio of 28% polystyrene, 68% titanium dioxide (average particle size of 0.1 microns), 2% dispersant (such as paraffin), 1.5% compatibility aid (such as polyethylene Diol 400) and 0.5% hindered phenolic antioxidant (such as antioxidant 2,8-di-tert-butyl-4-methylphenol) are added to a high-speed mixer and stirred evenly for casting or extrusion Molding, get the product, and test its performance.

Embodiment 2

[0024] Polystyrene reflective material, according to the ratio of 45% polystyrene, 54% titanium dioxide (average particle size of 0.5 microns), 0.5% dispersant (such as polymer wax), 0.3% compatibilizer (such as Polyethylene glycol 200) and 0.3% hindered phenolic antioxidant (such as antioxidant 2,8-di-tert-butyl-4-methylphenol) are added to the high-speed mixer and stirred evenly, and then cast or Extrude to obtain the product, and perform performance testing on it.

Embodiment 3

[0026] Polystyrene reflective material, according to the ratio of 66% polystyrene, 30% calcium carbonate (average particle size of 5 microns), 2% dispersant (such as stearic acid), 1.2% compatibilizer ( Such as polyethylene glycol 400) and 0.8% antioxidant (such as antioxidant 1010) are added to a high-speed mixer and stirred evenly, and cast or extruded to obtain the product, and its performance is tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com