Optical fiber coupler achieving scattered coupling and application thereof

A fiber coupler and fiber combiner technology, which is applied in the coupling, light guide, optics and other directions of optical waveguides, can solve the problems of reduced waveguide conditions, scattering, reflection and mode crosstalk, heat accumulation, etc., to reduce return loss. and mode crosstalk, preventing damage and destruction, eliminating the effect of crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

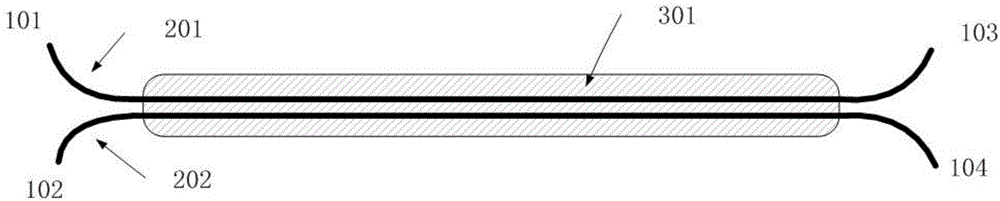

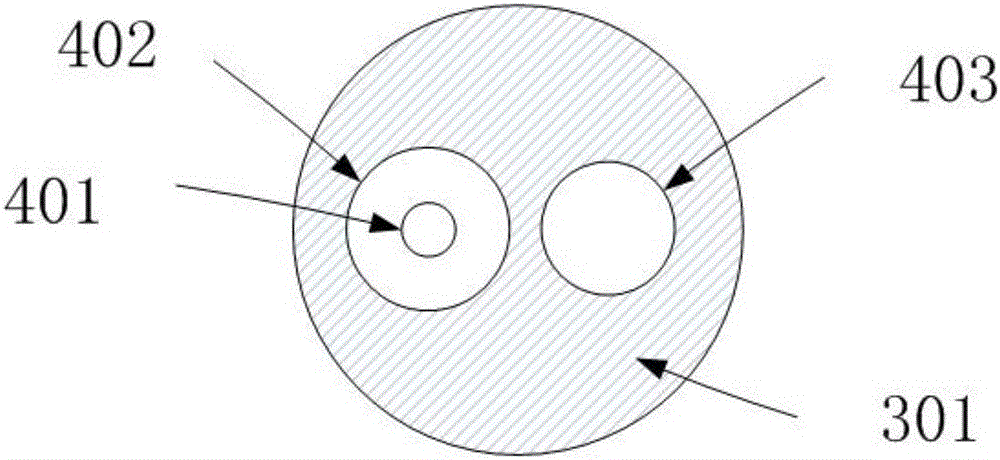

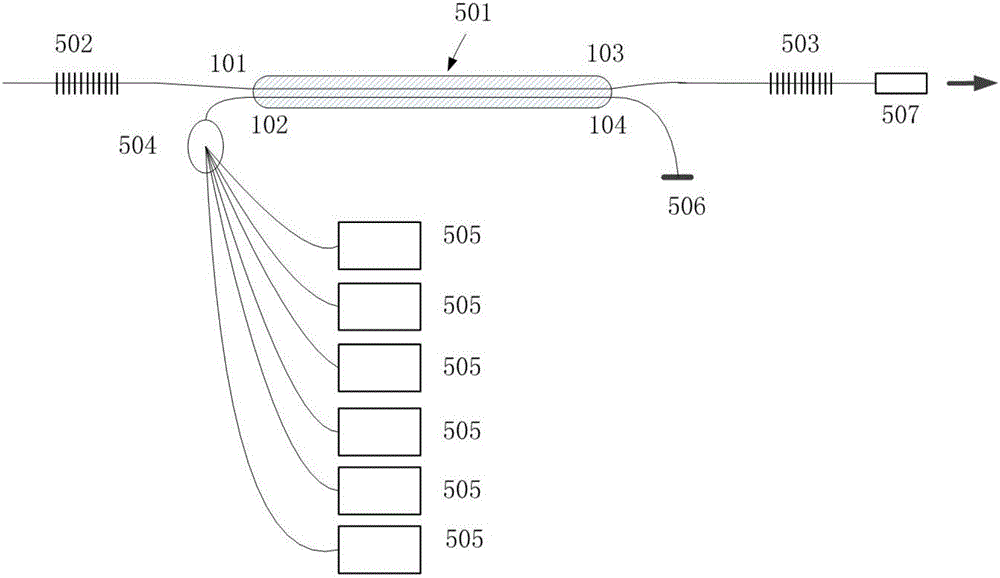

[0021] like image 3 Shown is a schematic structural diagram of the first fiber laser using the fiber coupler of the present invention. A fiber laser uses 6 independent semiconductor pump lasers 505, which are combined into one bundle through a 6x1 fiber combiner 504, and then enter the port 102 of the second optical fiber 202 of the fiber coupler 501 of the present invention. The first optical fiber 201 is an active optical fiber with an inner cladding 402 and a core 401, the core portion of which is doped with a rare earth element at a relatively low concentration. The first optical fiber 201 is engraved with fiber gratings on both sides of the coupling part as light reflectors 502 and 503, which constitute a laser resonator of the desired wavelength. The pump laser light is weakly coupled per unit length through the fiber coupler of the present invention, and the pump laser light in the optical fiber 202 is coupled into the inner cladding of the optical fiber 201 . The in...

Embodiment 2

[0023] like Figure 4 As shown, it is a schematic structural diagram of the second fiber laser using the fiber coupler of the present invention. A semiconductor laser is used as the seed light source 508, and the pulsed laser output from it is pre-amplified through the pre-optical amplifier 510, and then enters the port 101 of the first optical fiber of the fiber coupler of the present invention. A cladding optical power stripper for double-clad fiber is already included inside the preamplifier. The pumping source uses 6 independent semiconductor pumping lasers 505, which are combined into one bundle through a 6x1 fiber combiner 504, and then enter the port 2 of the second optical fiber of the fiber coupler 501 of the present invention. The first optical fiber 201 is an active optical fiber with an inner cladding 402 and a core 401, the core portion of which is doped with a rare earth element at a relatively low concentration. The first optical fiber 201 does not require fib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Horizontal spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com