Method for manufacturing thin film transistor

一种薄膜晶体管、制作方法的技术,应用在液晶显示领域,能够解决影响重掺杂漏极区和轻掺杂漏极区电子迁移率、离子均一性影响较大、工艺制备过程复杂等问题,达到避免二次蚀刻、离子均一性小、简化工艺制备过程的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

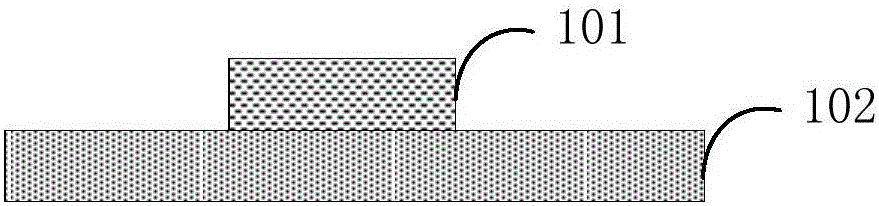

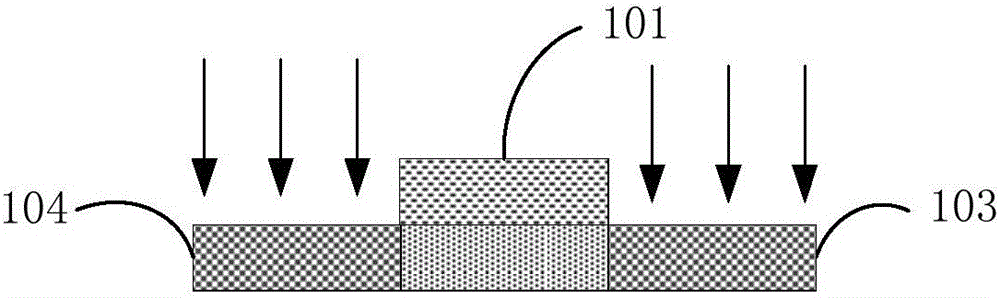

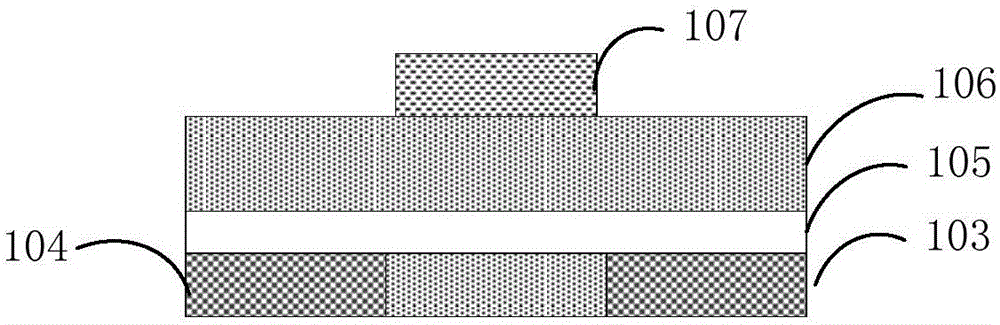

[0031] The following descriptions of the various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the invention may be practiced. The directional terms mentioned in the present invention, such as [top], [bottom], [front], [back], [left], [right], [inside], [outside], [side], etc., are only for reference The orientation of the attached schema. Therefore, the directional terms used are used to illustrate and understand the present invention, but not to limit the present invention. In the figures, structurally similar elements are denoted by the same reference numerals.

[0032] The implementation process of the embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] In view of the complicated preparation process of the thin film transistor, which leads to a long production cycle and is not conducive to production, the following improvements are made.

[0034] like ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com