A method and system for reconstructing three-dimensional microstructure of materials

A microstructure and reconstruction system technology, applied in the analysis of materials, material analysis using wave/particle radiation, image enhancement, etc., can solve the problem of inaccurate division of components, achieve wide division and avoid secondary etching Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

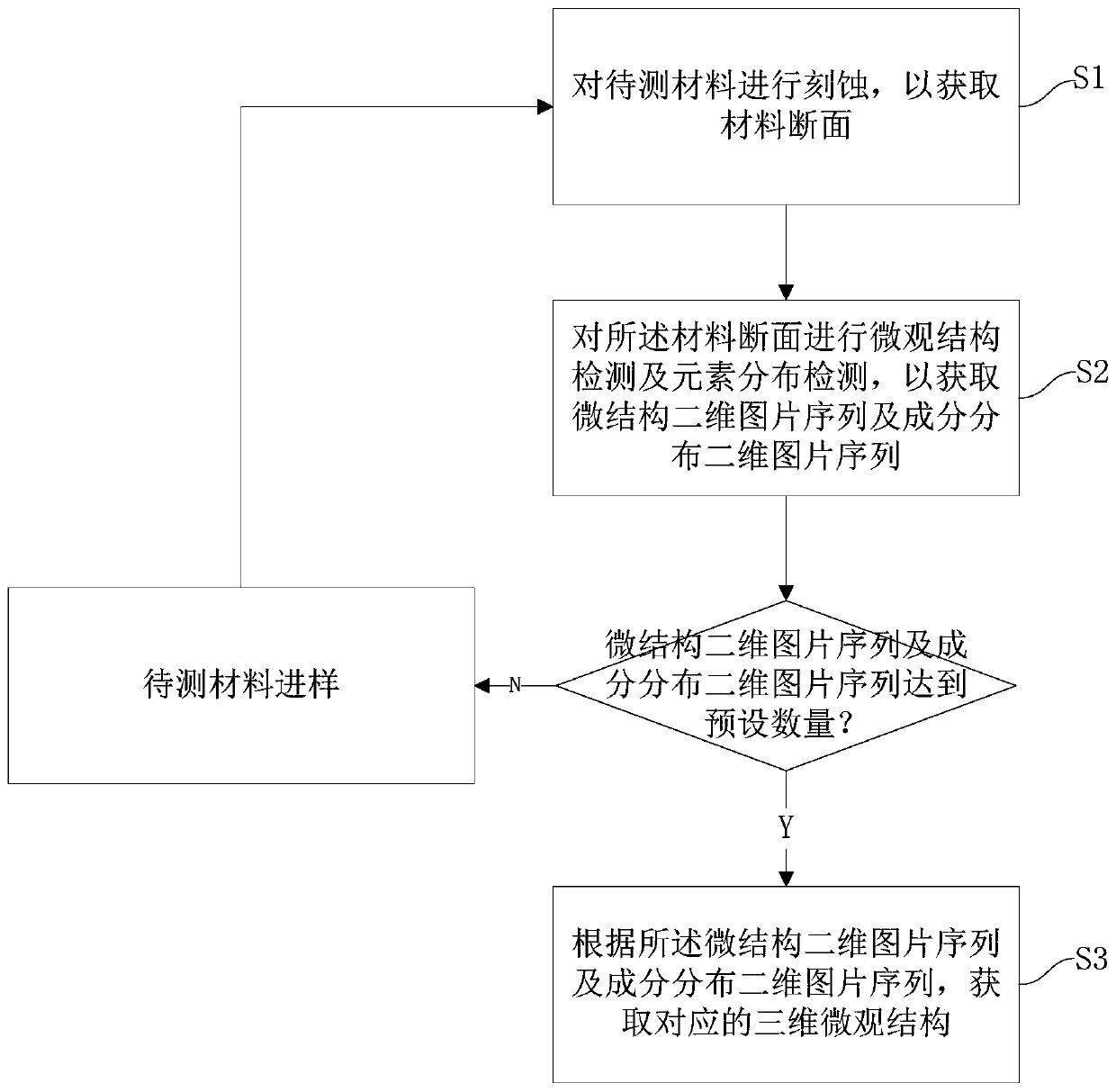

[0044] figure 1 It is a flowchart of a material three-dimensional microstructure reconstruction method in this embodiment, such as figure 1 As shown, a method for reconstructing the three-dimensional microstructure of a material in this embodiment includes:

[0045] S1. Etching the material to be tested to obtain the cross section of the material;

[0046] In this step, a focused ion beam device is used to etch the material to be tested to obtain a cross section of the material; the focused ion beam is an ion beam generated by a Ga ion source, and the focused ion beam is accelerated by an ion gun to etch the material; the focused ion beam The accelerating voltage is adjusted according to different material properties.

[0047] In this embodiment, the accelerating voltage intensity of the focused ion beam emitting gun can be set to 20kV, and the generated accelerated ion beam can be used to perform cross-sectional etching on the material to be tested, and the cross-sectional ...

Embodiment 2

[0072] In this embodiment, before the reconstruction of the three-dimensional microstructure of the material, it also includes: a material preparation process, specifically:

[0073] A certain amount of lithium-ion battery cathode active material (lithium cobalt oxide), conductive agent (carbon black), and binder (PVDF) are fully dry-ground according to a certain ratio, and a certain amount of NMP (N-methylpyrrolidone) is added to carry out wet grinding;

[0074] The ground slurry is scraped on the aluminum foil to form a porous material coating with a thickness of about 100 microns;

[0075] Cut the material into a size of 3mm×3mm, and conduct gold evaporation;

[0076] The gold-plated sample is placed on the sample stage, and the detection area is determined by the scanning electron microscope device.

[0077] In this embodiment, by using the three-dimensional microstructure reconstruction method, using the distribution of elemental components as the standard for the divis...

Embodiment 3

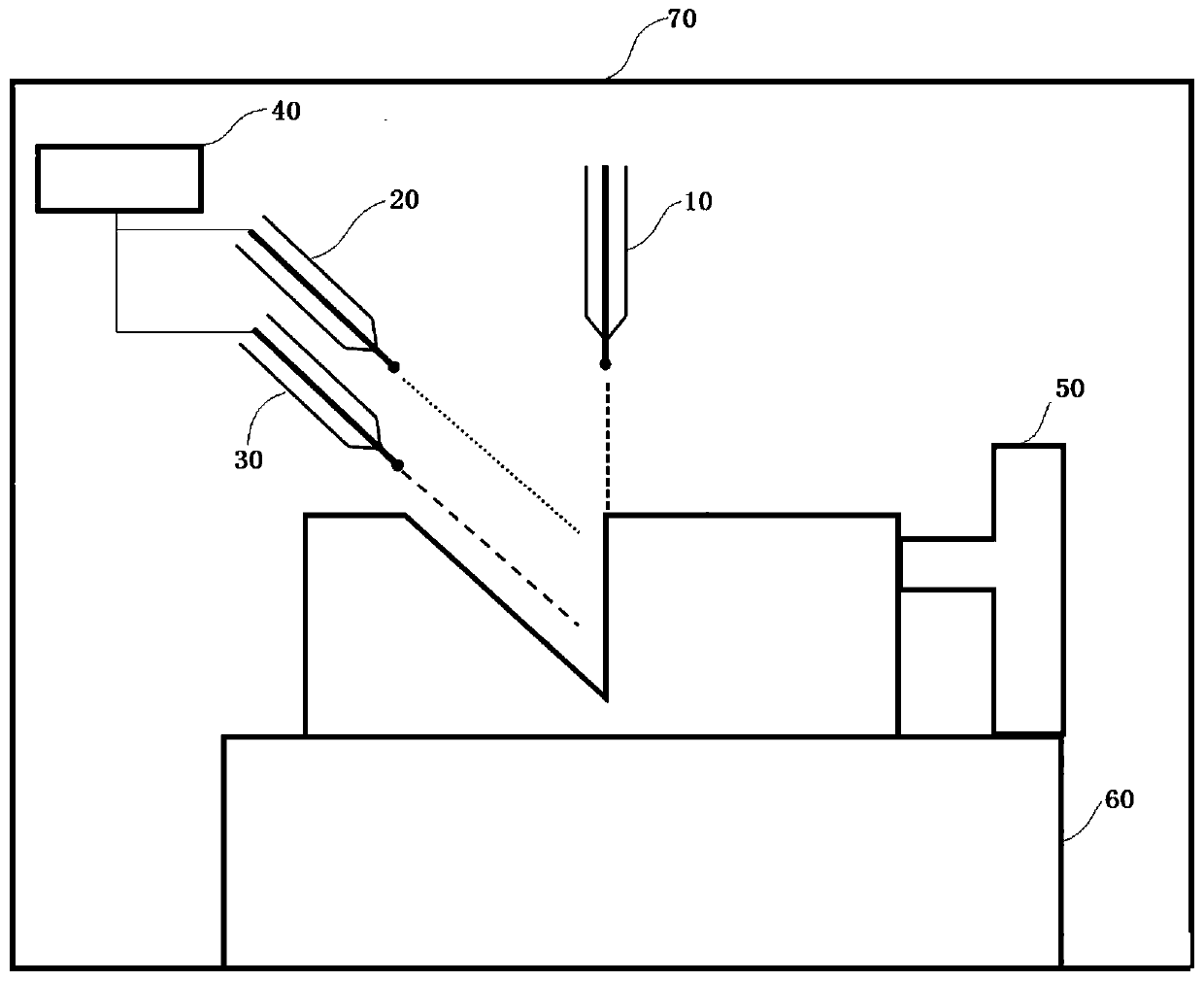

[0079] figure 2 It is a structural diagram of a material three-dimensional microstructure reconstruction system in this embodiment, such as figure 2 As shown, a material three-dimensional microstructure reconstruction system in this embodiment includes:

[0080] The focused ion beam device 10 is used to etch the material to be tested to obtain a cross section of the material;

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com