A clutch disc assembly assembly manipulator

A clutch disc and assembly assembly technology, applied in the field of clutch production, can solve the problems of slow speed, many parts, small shape, etc., and achieve the effects of high efficiency, fast positioning speed and short positioning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following is a further detailed description through specific implementations:

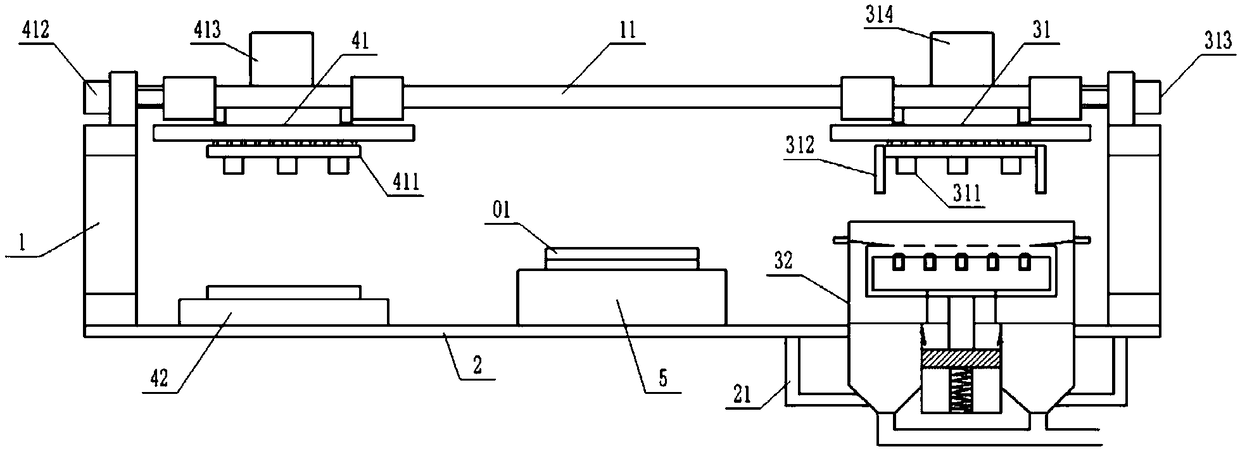

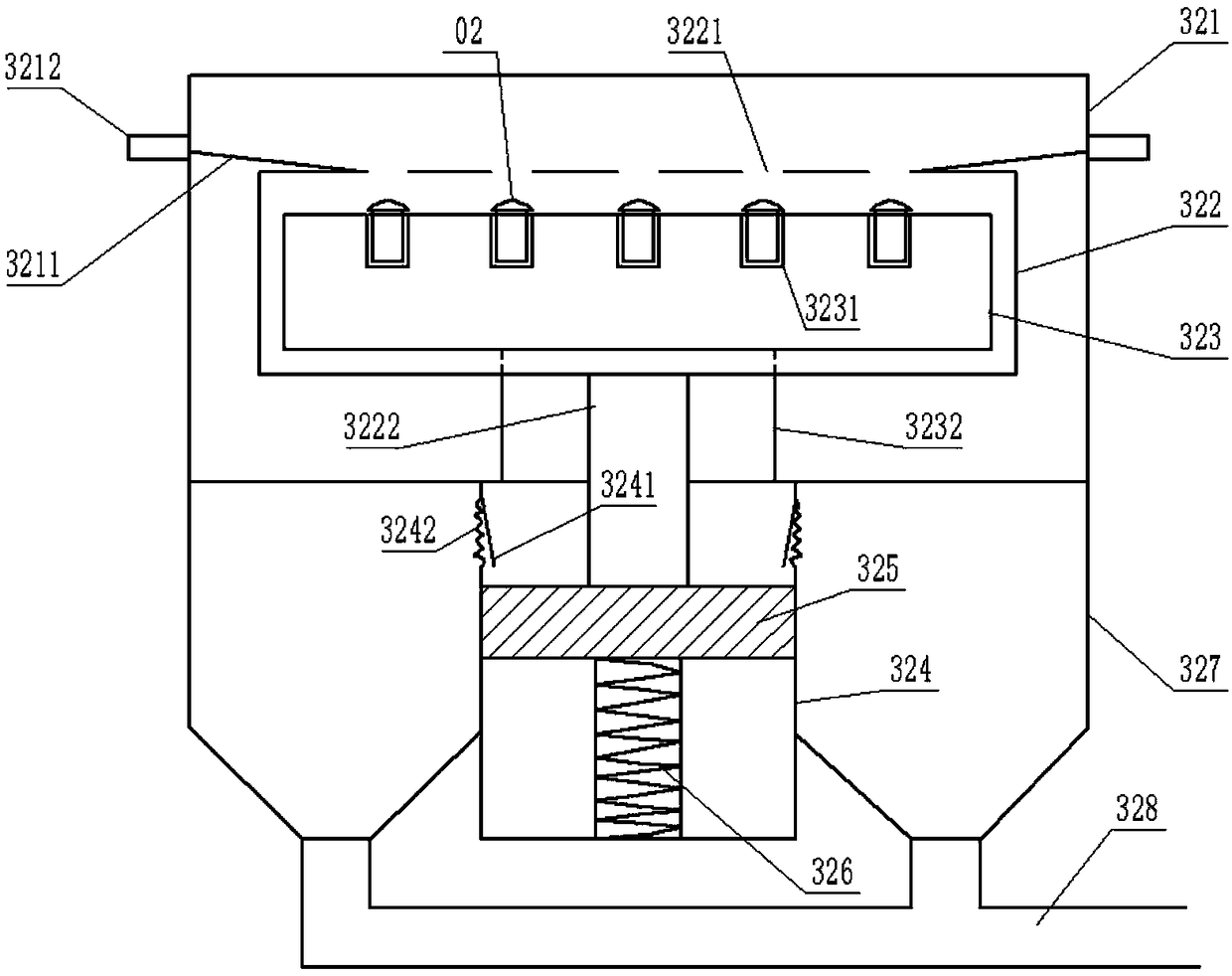

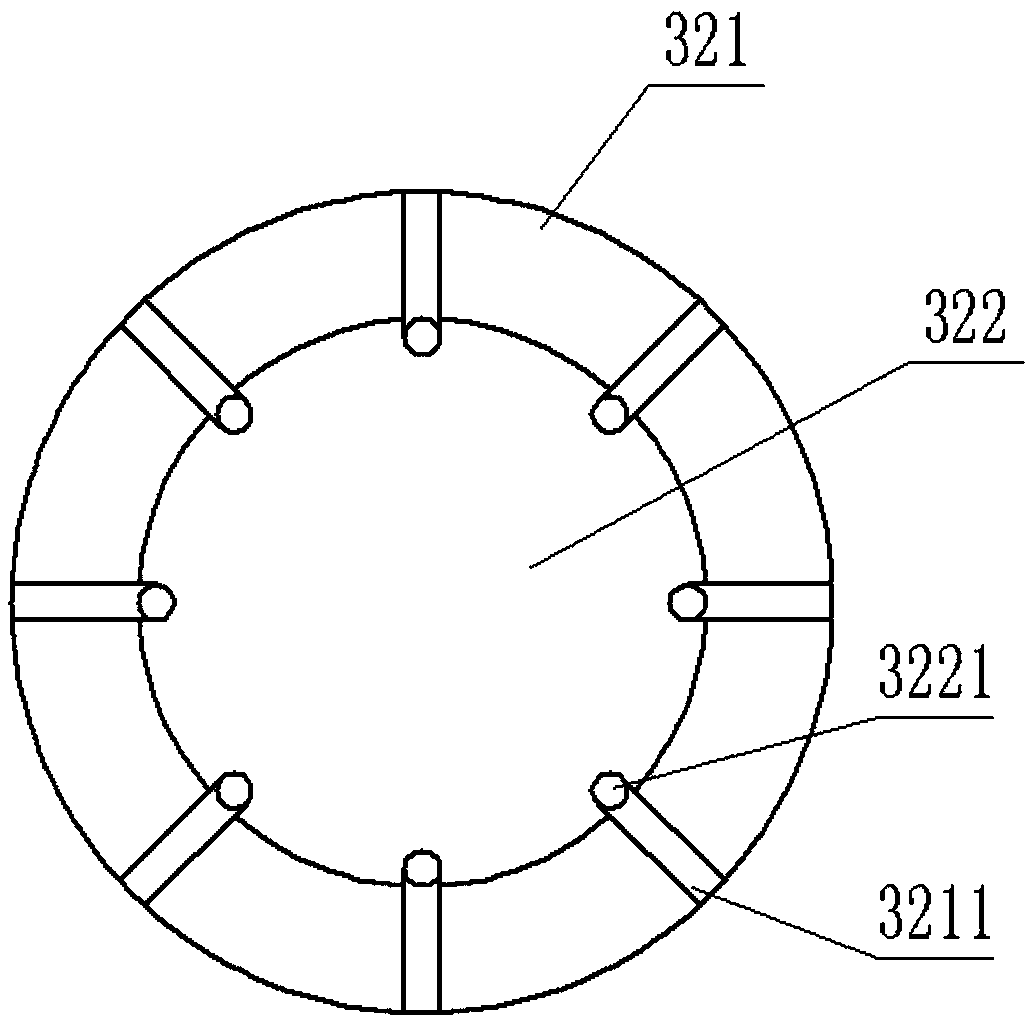

[0019] Instruction attached Figure 1 to 5 The reference signs in include: clutch assembly 01, rivet 02, frame 1, rail 11, base 2, bracket 21, rivet grasping mechanism 31, suction nozzle 311, extrusion rod 312, first air cylinder 313, first Hydraulic cylinder 314, rivet positioning mechanism 32, outer barrel 321, conveying plate 3211, rivet feeding vibration plate 3212, hollow column 322, through hole 3221, piston rod 3222, positioning plate 323, first positioning hole 3231, external groove 324, single Toward door 3241, filter screen 3242, piston 325, first spring 326, slag collection chamber 327, slag pipe 328, wave plate grasping mechanism 41, suction cup structure 411, second cylinder 412, second hydraulic cylinder 413, wave plate Positioning mechanism 42, positioning barrel 421, rolling ball 422, support plate 423, motor 424, first transmission gear 425, fixed rod 426, second transmissi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com