Method and device for improving repetition frequency of laser

A repetition frequency and laser technology, applied in the laser field, can solve the problems of increasing the difficulty of mode locking, weak nonlinear effect, and increasing the difficulty of the process, and achieve the effect of reducing the difficulty of the assembly process, increasing the repetition frequency, and reducing the difficulty of mode locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

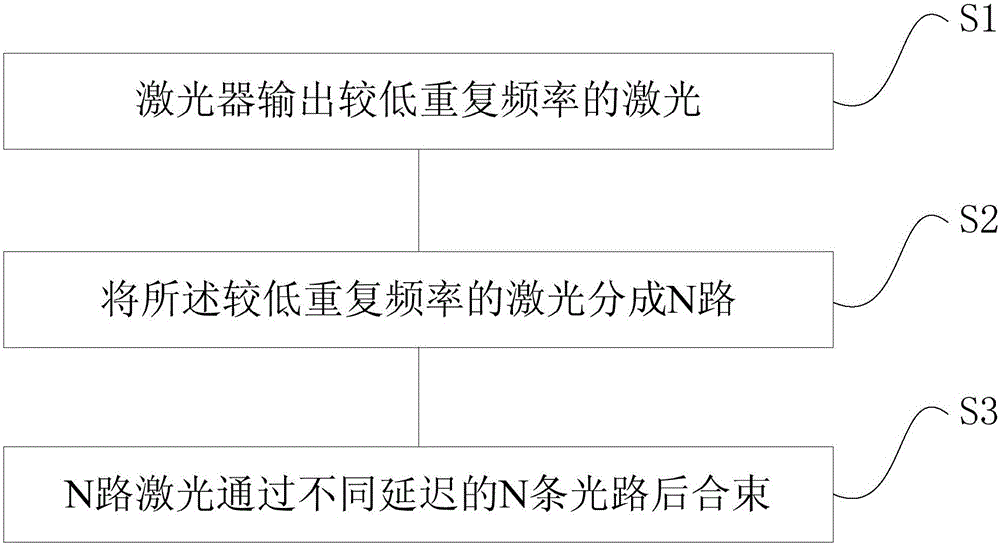

[0025] figure 1 A method of increasing the repetition rate of a laser is shown, comprising the steps of:

[0026] A method for increasing the repetition rate of a laser, comprising the steps of:

[0027] S1. The laser outputs laser with a lower repetition rate;

[0028] S2. Divide the laser light with a lower repetition rate into N paths;

[0029] S3. N laser beams are combined after passing through N optical paths with different delays.

[0030] As preferably, in the step S3, the delays of the N optical paths are respectively τ 1 , τ 2 , τ 3 ...τ N , the delay difference between two adjacent optical paths

[0031] Preferably, in the step S1, the lower repetition frequency output by the laser is RF, and in the step S3, the laser repetition frequency after beam combining is equal to N×RF.

[0032] Preferably, the color difference between the N optical paths is less than 0.0003 ps / nm, so that the output laser pulse width can be restored to the input laser pulse width; ...

Embodiment 2

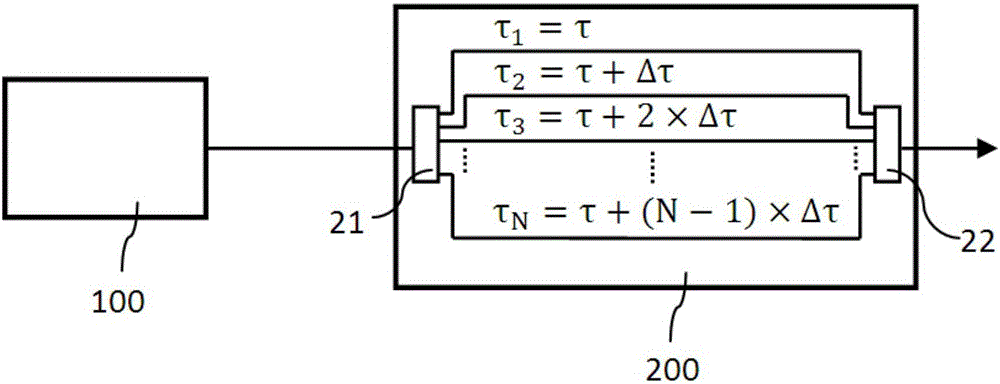

[0034] Figure 2 to Figure 4 A device for increasing the laser repetition rate is provided, including a laser 100 for outputting laser light, a TDM module 200 for increasing the laser repetition rate, and the TDM module 200 is used to divide the laser light into N paths, and after passing through N optical paths with different delays Be bundled.

[0035] In this embodiment, 100 uses a femtosecond fiber laser with a repetition rate of 72 MHz, a wavelength of 1550 nm, and a pulse width of 120 fs.

[0036] Preferably, the TDM module 200 includes a first optical splitter 21 and a second optical splitter 22, the first optical splitter 21 is used to divide the laser into N paths, and the second optical splitter The splitter 22 is used to combine N paths of light. In this embodiment, both the first optical splitter 21 and the second optical splitter 22 are 1×16 optical splitters.

[0037] Preferably, the laser light is divided into N paths and combined after passing through N light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com