Induction motor feedback type indirect vector control system and control method thereof

A technology of induction motor and vector control, applied in vector control system, motor generator control, electronic commutation motor control, etc. slow response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

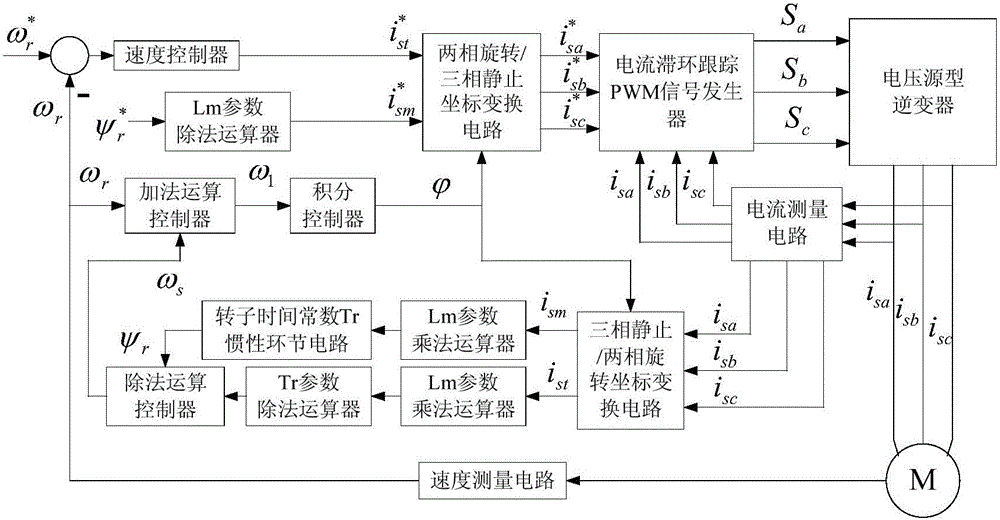

[0079] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the following in conjunction with the accompanying drawings and preferred embodiments, a kind of induction motor feedback type indirect vector control system and its control method according to the present invention, Its specific implementation, structure, feature and effect thereof are described in detail as follows.

[0080] The present invention is an induction motor feedback type indirect vector control system, including a speed controller, L m Parameter divider, adder controller, integral controller, divider controller, T r Parameter divider, high cut-off frequency low-pass filter, three-phase stationary / two-phase rotating coordinate transformation circuit, two-phase rotating / three-phase stationary coordinate transformation circuit, current hysteresis tracking PWM signal generator, voltage source inverter and induction motors;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com