A kind of processing technology of thin cigarette

A processing technology and slim cigarette technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of high stalk content rate of tobacco leaves, high draw resistance standard, large single box consumption, etc., and achieve the elongation rate of tobacco sheets High efficiency, reasonable structure of leaf shreds, high utilization rate of feed liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

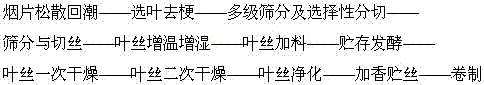

[0028] A processing technique for slim cigarettes, comprising the steps of:

[0029] (1) Loosening and regaining moisture: the raw materials of golden leaf (Aishang) slim cigarette leaf group formula are sent to the conditioning machine for loosening and moisture regaining after unpacking and slicing. The outlet temperature of the leaves is (40±1)℃, Moisture content is (17.5±1)%;

[0030] (2) Leaf selection and destemming: after moisture resurgence, the tobacco sheets are sent to the spectral de-stemming machine for online leaf selection and de-stemming, and the tobacco leaves with a stem diameter of 1.2mm or more are removed through spectral de-stemming, and the removed tobacco leaves enter the batch after manual de-stemming secondary cigarettes;

[0031] (3) Multi-stage screening and selective slitting of smoked sheets: Sieve the smoked sheets after spectral removal, and cut the area of 550mm 2 More than 70% of the smoke slices enter the slicer for selective re-cutting: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com