Composite preparation for accelerating tobacco mellowing

A compound preparation and technology of tobacco leaf alcohol, which is applied in the field of tobacco processing, can solve the problems of limiting the scale and application range of natural aging, inconsistent optimal aging cycle of tobacco leaves, and large warehouse occupied by tobacco leaf aging, achieving the effect of shortening the aging cycle and important application value , the effect of shortening the alcoholization cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The composite preparation for accelerating the alcoholization of tobacco leaves provided in this example includes microbial preparations and biological enzymes;

[0033] The microbial preparation includes two kinds of Bacillus subtilis bacterial liquid and Sphingomonas bacterial liquid;

[0034] The Bacillus subtilis bacterial liquid is prepared as follows: take Bacillus subtilis strain xp (the preservation number of the China Type Culture Collection Center is: CCTCCNo: M2011452), LB liquid medium, 30 ° C, 200 rpm shaker Cultivate and amplify, use the sterile culture solution as the blank control, record the absorbance value OD at 600nm of the bacterial solution 600 , when OD 600 =6.0, as the application of bacterial liquid; at this time, the number of bacterial cells in the bacterial liquid is roughly 6 billion / mL;

[0035] The sphingomonas bacterial liquid is prepared as follows: take sphingomonas strain xp (the preservation number of the China Center for Typical Cu...

Embodiment 2

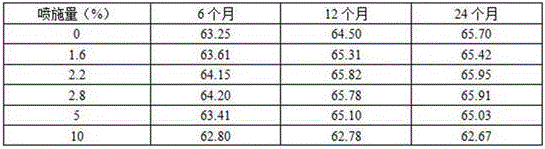

[0046] Taking the compound preparation for accelerating the alcoholization of tobacco leaves prepared in Example 1 (Bacillus subtilis bacterial liquid: Sphingomonas bacterial liquid: biological enzyme = 0.7:0.8:0.7) as an example, when it is used for tobacco leaf treatment, The specific process is as follows:

[0047] Take the fresh tobacco leaves after initial roasting (Luzhou-flavor tobacco leaves B2F, the same as Comparative Example 1), and spray the uniformly mixed compound preparation on the surface of the tobacco leaves by spraying, and the spraying amount is 2.2% of the mass of the tobacco leaves; It is directly threshed and re-roasted, then stored in storage, and alcoholized under natural conditions.

[0048] The sensory evaluation and measurement results for tobacco leaves in different periods are as follows:

[0049] Tobacco leaves after threshing and rebaking: the sensory quality score is 60.25 points, the starch content in the tobacco leaves is 5.80%, the protein ...

Embodiment 3

[0054] Taking the compound preparation for accelerating the alcoholization of tobacco leaves prepared in Example 1 (Bacillus subtilis bacterial liquid: Sphingomonas bacterial liquid: biological enzyme = 0.7:0.8:0.7) as an example, when it is used for tobacco leaf treatment, The specific process is as follows:

[0055] Take the fresh tobacco leaves after initial roasting (Luzhou-flavor tobacco leaves B2F, the same as Comparative Example 1), and spray the uniformly mixed compound preparation on the surface of the tobacco leaves by spraying, and the spraying amount is 2.2% of the mass of the tobacco leaves; Store under natural conditions for 30 days (compared with Example 2, increase the treatment of storing under natural conditions for 30 days), then threshing and re-roasting, storage, and alcoholization under natural conditions.

[0056] The sensory evaluation and measurement results for tobacco leaves in different periods are as follows:

[0057] Tobacco leaves after threshin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com