An Economical Forming Method of Three-jaw Force Transmission Mechanism

A molding method and economical technology, applied in auxiliary devices, auxiliary welding equipment, welding/welding/cutting items, etc., can solve the problems of complex process and high cost, and achieve the effect of simple process, high connection strength and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

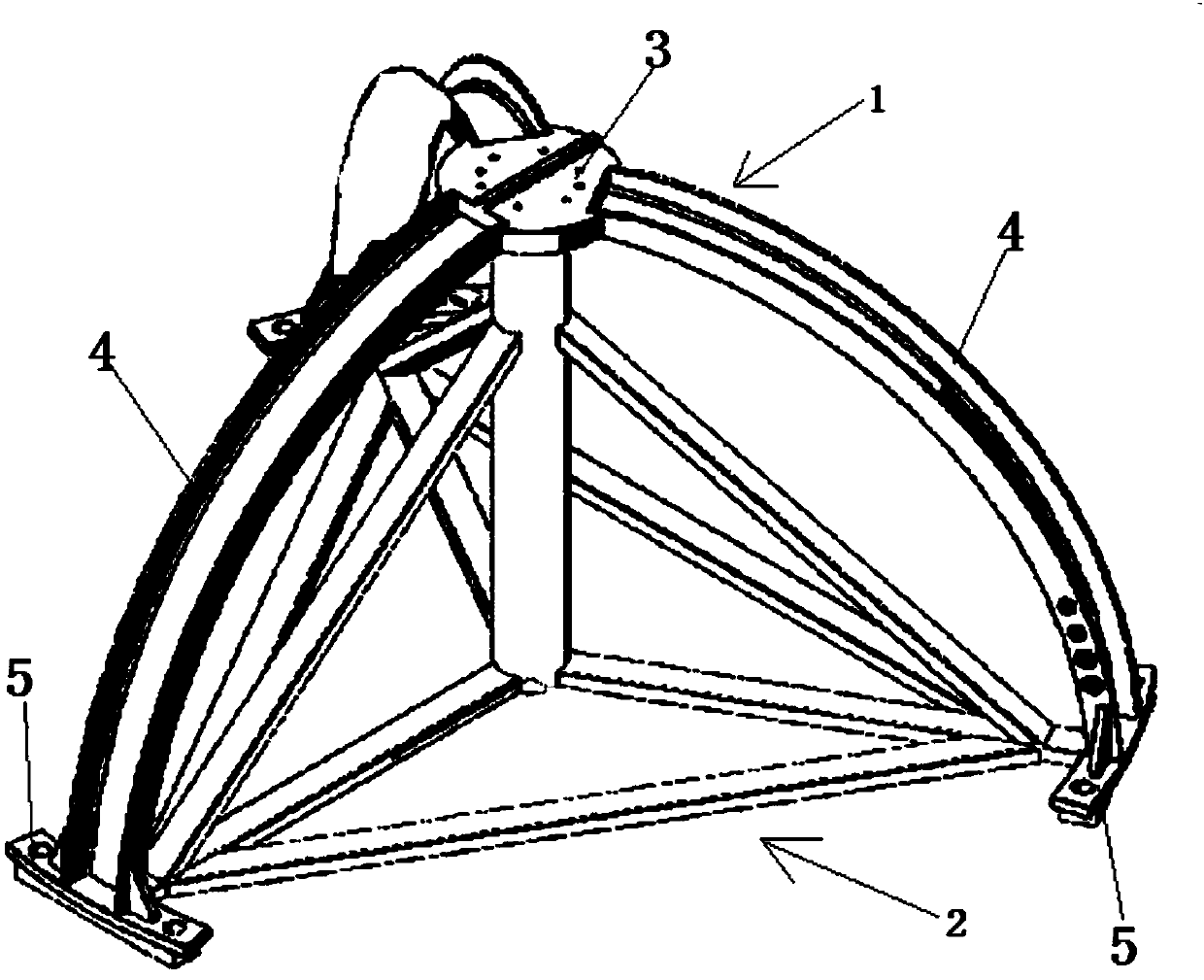

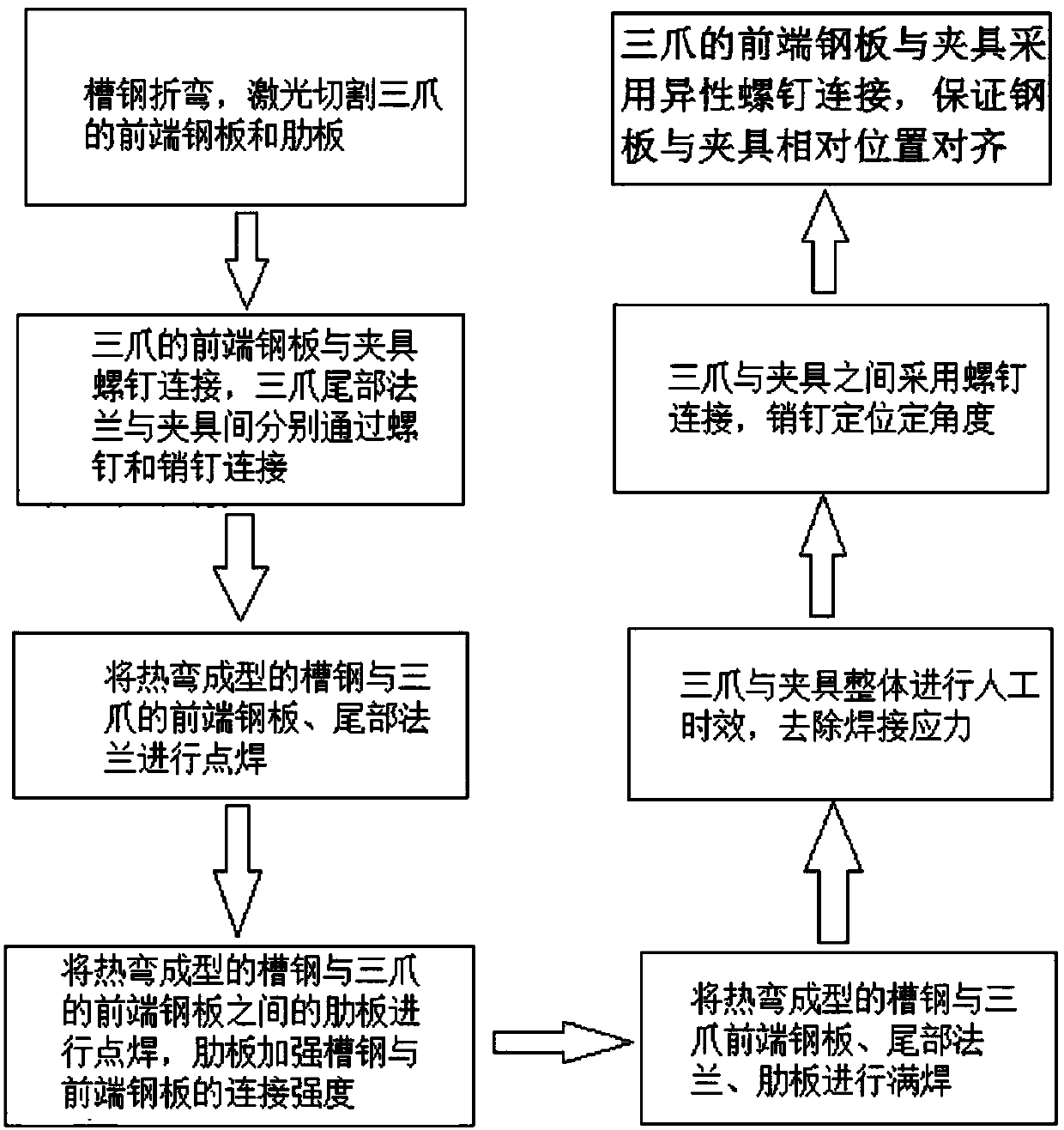

[0018] Implementation case: channel steel bending, laser cutting the front steel plate and rib plate of the three claws; the front steel plate 3 of the three claws 1 is connected to the fixture 2 with screws, and the tail flange 5 of the three claws 1 is connected to the fixture through six screws and two respectively. connect the hot-bent channel steel with the front-end steel plate 3 and tail flange 5 of the three-jaw 1; spot-weld the rib plate between the hot-bend-formed channel steel and the front-end steel plate 5 of the three-jaw 1 Welding, the rib plate strengthens the connection strength between the channel steel and the front steel plate 3; the hot-bent channel steel is fully welded to the front steel plate 3, tail flange 5, and rib plate 4 of the three jaws 1; the three jaws 1 and the fixture 2 are integrally welded Artificial aging is carried out to remove welding stress; the three claws 1 and the fixture 2 are connected by screws, and the pins are positioned at a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com