Rolling distributing equipment

A technology for rolling materials and equipment, applied in supply devices, manufacturing tools, etc., can solve problems such as affecting production efficiency, powder adhesion, and instability of design and color, and achieve the effect of simple structure and reduced downtime maintenance time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

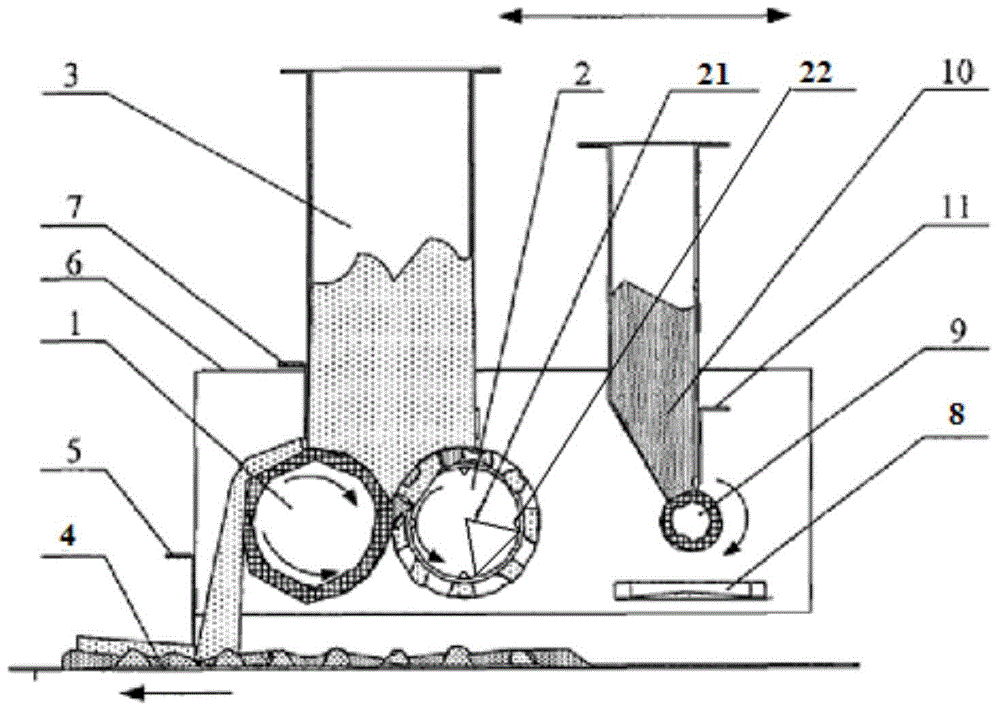

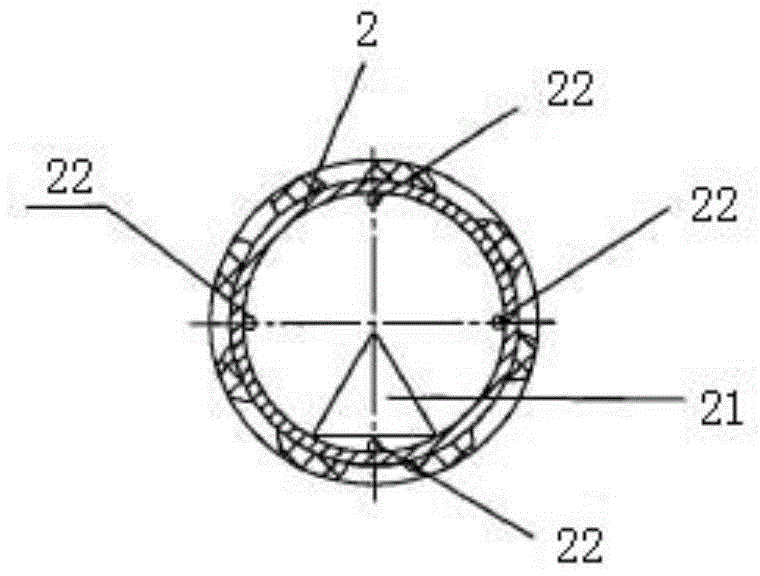

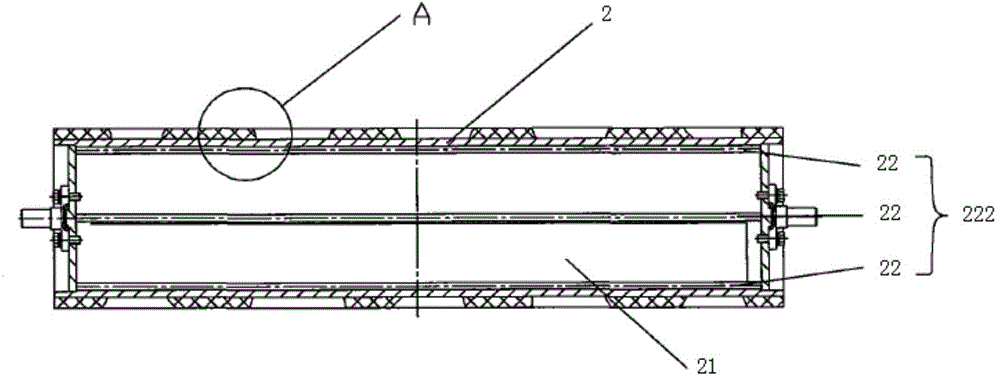

[0026] figure 1 It is a structural schematic diagram of the rolling material distribution device of the present invention. Such as figure 1 As shown, the main structure of the rolling material distribution device of the present invention includes a smooth roller 1, an engraved roller 2, a micropowder flower hopper 3 and a mobile filler connecting frame 6, and the left side of the smooth roller 1 is provided with a powder for scraping The powder scraper 5 of the material is connected with the mobile filler connecting frame 6; the engraved roller 2 is arranged on the right side of the smooth roller 1, and the outer surface of the engraved roller 2 is provided with a pit for accommodating the powder. The powder slips from the pit of the engraved roller 2 and falls on the powder-bearing carrier 4 under the extrusion state; the fine powder flower hopper 3 is arranged above the smooth roller 1 and the engraved roller 2, and passes through the smooth roller 1 and the The interactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com